Mechanism suitable for NTC442 diamond wire cutting device

A diamond wire cutting and bushing technology, which is used in fine working devices, working accessories, stone processing equipment, etc., can solve the problems of silicon wafer thickness and surface requirements that cannot meet the requirements, long distance of the main roller, and unstable cutting. Achieve the effect of simple structure, high processing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

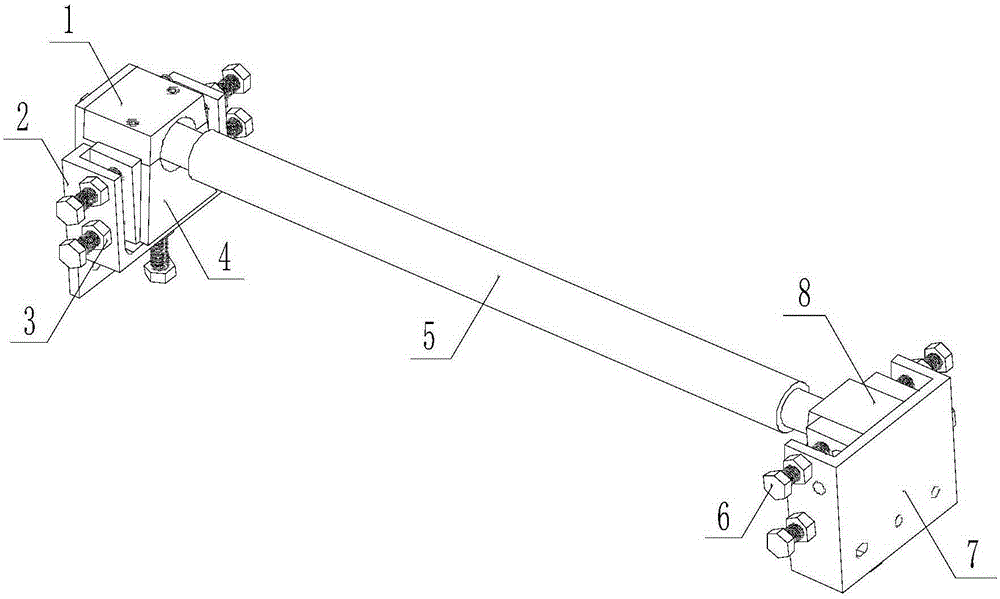

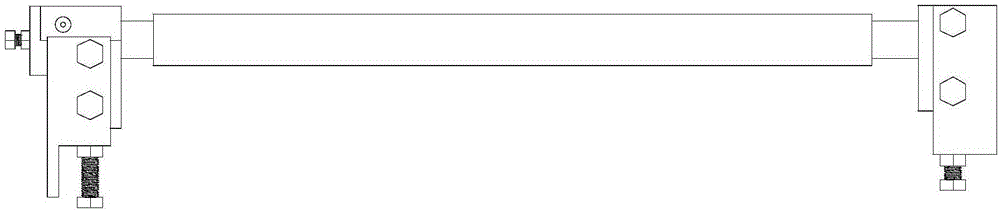

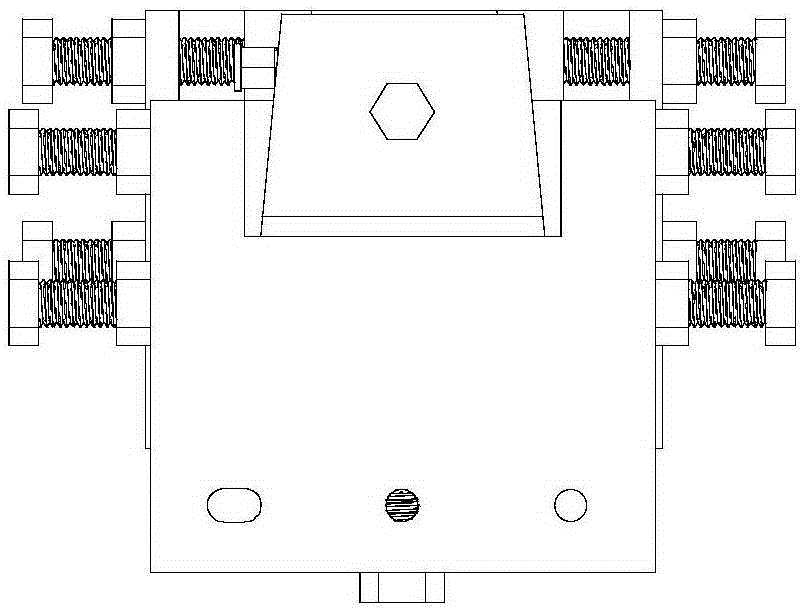

[0017] Examples such as figure 1 , figure 2 and image 3 As shown, a mechanism suitable for NTC442 diamond wire cutting device, including a pressing block 1, a left bushing frame 2, a nut 3, a left square bushing 4, a half shaft 5, a bolt 6, a right bushing frame 7 and a right square shaft Cover 8; the top surface of the briquetting block 1 is provided with a mounting hole, the bottom surface of the briquetting block 1 is provided with a semicircular groove, and the briquetting block 1 is fixedly installed on the top surface of the left square shaft sleeve 4 through the bolt 6, and the left square shaft A semicircular groove is provided on the top surface of the sleeve 4, and a groove is provided on the left shaft sleeve frame 2, and the left square shaft sleeve 4 is installed in the groove of the left shaft sleeve frame 2 by bolts 6 and nuts 3, and the right Square axle sleeve 8 is provided with cylindrical hole, and described right axle sleeve frame 7 is provided with gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com