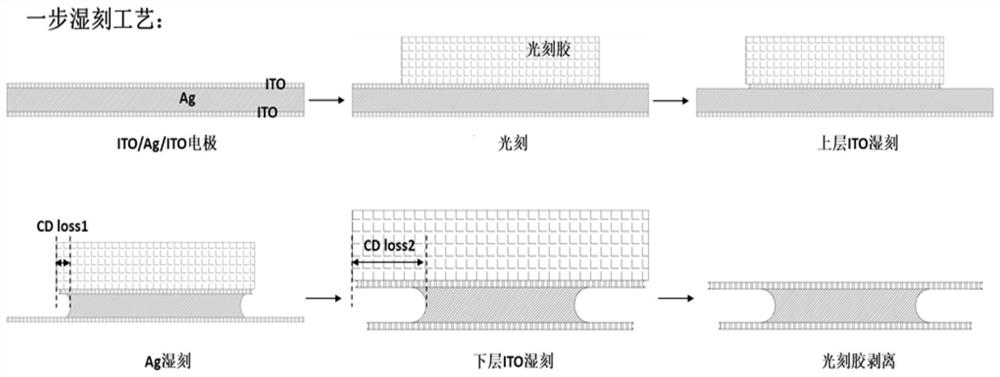

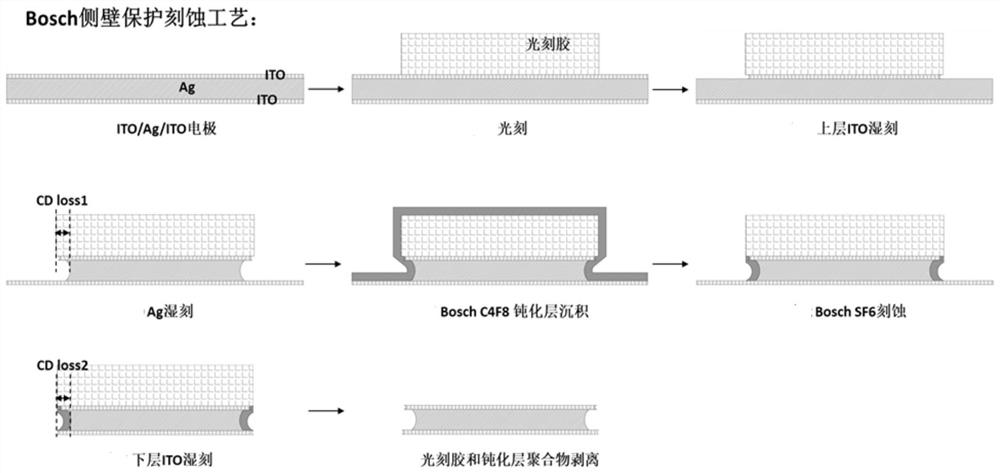

Method for preparing high-precision silver electrode by side wall protection process

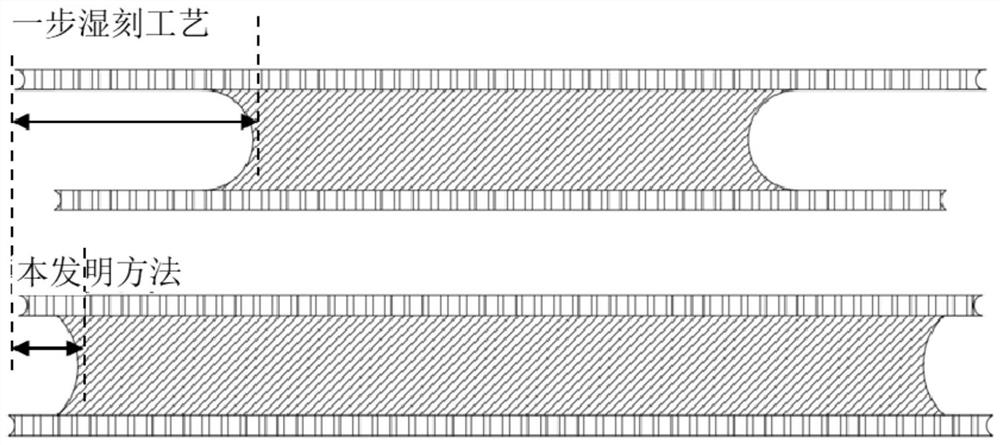

A sidewall protection, high-precision technology, applied in circuits, electrical components, electrical solid-state devices, etc., can solve the problems of inability to apply Ag electrode structure, large AgCDloss, poor aluminum conductivity, etc., to meet the needs of ultra-high-resolution display , The effect of reducing CDloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-precision silver electrode by a sidewall protection process, comprising the following steps:

[0035] 1) The ITO / Ag / ITO structure is a three-layer sandwich structure, which is ITO layer, Ag layer and ITO layer from bottom to top, and its thickness is 100A, 1000A, 100A from bottom to top; photolithography is performed first, and PR Thickness 1μm, curing energy 50mj;

[0036] 2), then wet etching the upper layer ITO not protected by the photoresist, using 8wt% oxalic acid etching, time 20s to remove the upper layer ITO, and then wet etching the Ag layer with nitric acid / phosphoric acid / acetic acid mixture for 10s to remove the Ag layer; Nitric acid / phosphoric acid / acetic acid mixture, the mass fraction ratio is 20%:40%:40%.

[0037] 3), and then proceed to C 4 f 8 Deposit passivation layer, process parameters: time 10s, power supply power 300W, C 4 f 8 The flow rate is 10sccm, the pressure is 5mt, and the temperature is 50°C; it is used ...

Embodiment 2

[0043] A method for preparing a high-precision silver electrode by a sidewall protection process, comprising the following steps:

[0044] 1) The ITO / Ag / ITO structure is a three-layer sandwich structure, and its thickness is 500A, 5000A, and 500A in turn; for photolithography, the PR thickness is 2μm, and the curing energy is 500mj;

[0045] 2) Remove the upper layer of ITO at the position not protected by the photoresist, use 4wt% oxalic acid wet etching for 50s, remove the upper layer of ITO; then perform Ag wet etching, nitric acid / phosphoric acid / acetic acid mixed solution wet etching for 20s, remove the Ag layer; The nitric acid / phosphoric acid / acetic acid mixed acid used has a mass fraction ratio of 30%:30%:40%.

[0046] 3), C 4 f 8 Deposit passivation layer, process parameters: time 30s, power supply power 500W, C 4 f 8 The flow rate is 20sccm, the pressure is 10mt, and the temperature is 50°C. Both the photoresist surface and the exposed Ag surface area on the und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Curing energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com