Method for preparing high-precision silver electrode through self-limiting wet etching

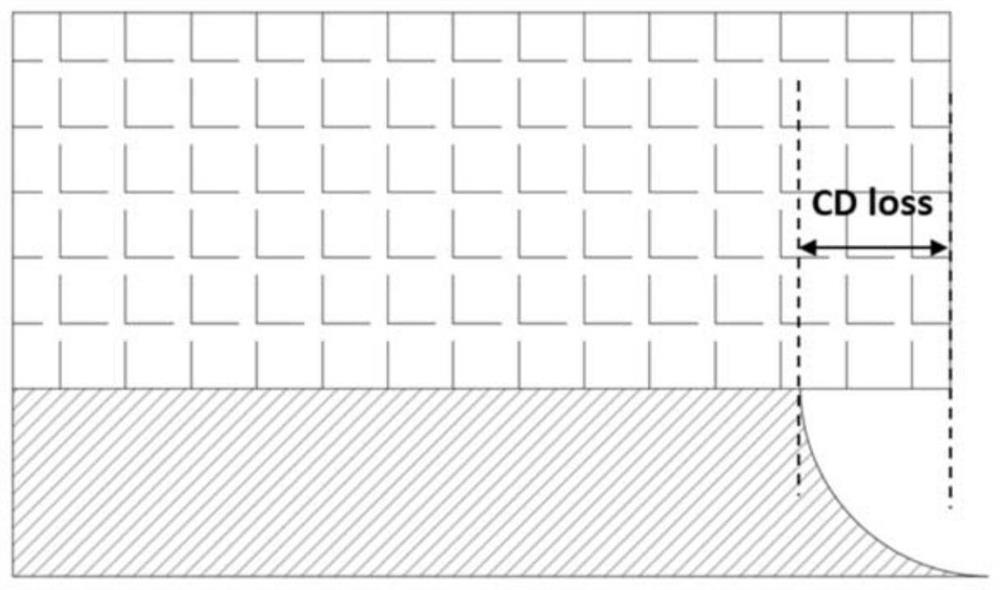

A wet etching, self-limiting technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of long etching time, low aluminum reflectivity, poor aluminum conductivity, etc., to reduce CDloss, high Reflective properties, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

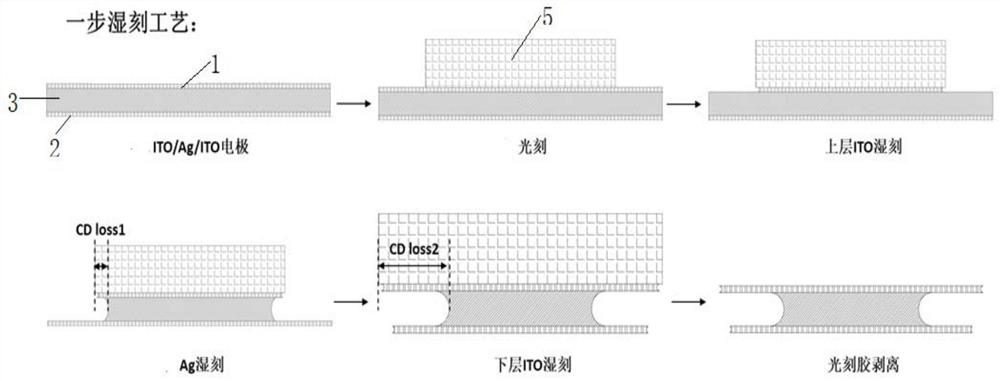

[0035] A method for preparing high-precision silver electrodes by self-limiting wet etching, comprising the following steps:

[0036] 1) Deposit a 50A ITO layer by PVD sputtering on the silicon substrate first, then deposit a 500A Ag layer, and finally deposit an ITO layer with a thickness of 50A;

[0037] 2) Photolithography, PR thickness 1μm, energy 100mj;

[0038] 3) Wet etching the upper layer of ITO oxalic acid that is not protected by photoresist, using 2wt% oxalic acid aqueous solution, wet etching for 5s;

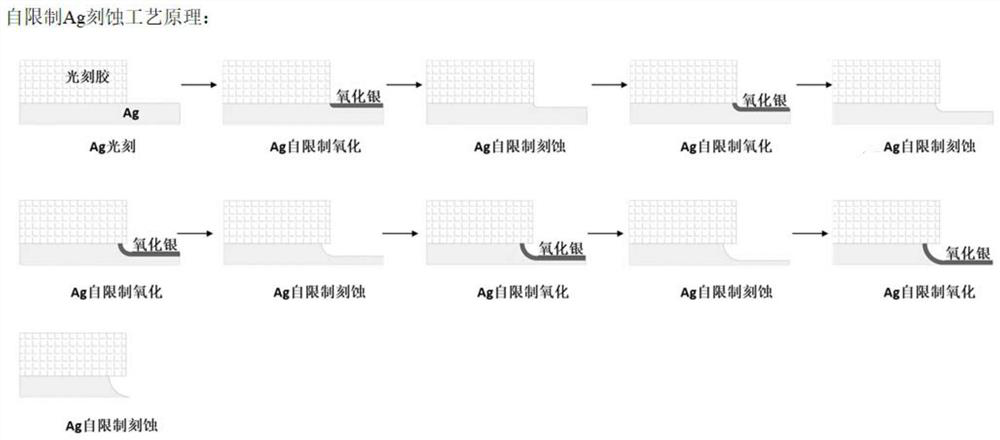

[0039] 4) Ag self-limiting oxidation, using a hydrogen peroxide solution with a volume fraction of 2%, oxidizing for 2s;

[0040] 5) Ag self-limiting etching, using 1% nitric acid solution, wet etching for 5s;

[0041] 6) Repeat step 4) and step 5) several times in sequence until the Ag etching is completed, the silver is bright silver, and the disappearance of the bright silver on the surface of the substrate indicates that the etching is complete;

[0042] 7) T...

Embodiment 2

[0046] A method for preparing high-precision silver electrodes by self-limiting wet etching, comprising the following steps:

[0047] 1) First deposit a 500A ITO layer by PVD sputtering on the silicon substrate, then deposit a 3000A Ag layer, and finally deposit a thickness of 500A;

[0048] 2) Photolithography, PR thickness 5μm, energy 500mj;

[0049] 3) Wet etching of the upper layer of ITO with oxalic acid, the part not coated with photoresist was wet-etched with 10% aqueous solution of oxalic acid for 2 seconds;

[0050] 4) After wet etching with oxalic acid, use Ag self-limiting oxidation, use APM solution with a volume fraction of 30% hydrogen peroxide:concentrated hydrochloric acid:water=1:1:5, and oxidize for 2s;

[0051] 5) Perform Ag self-limiting etching again, and then use 2wt% nitric acid solution for wet etching for 4s;

[0052] 6) Repeat step 4) and step 5) several times in sequence until the Ag etching is completed, the silver is bright silver, and the disappea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com