A motor for range hood

A technology of range hoods and magnetic plates, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of occupying axial space, inconvenient installation, and unfavorable miniaturization of motors, so as to improve heat dissipation capacity and realize change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

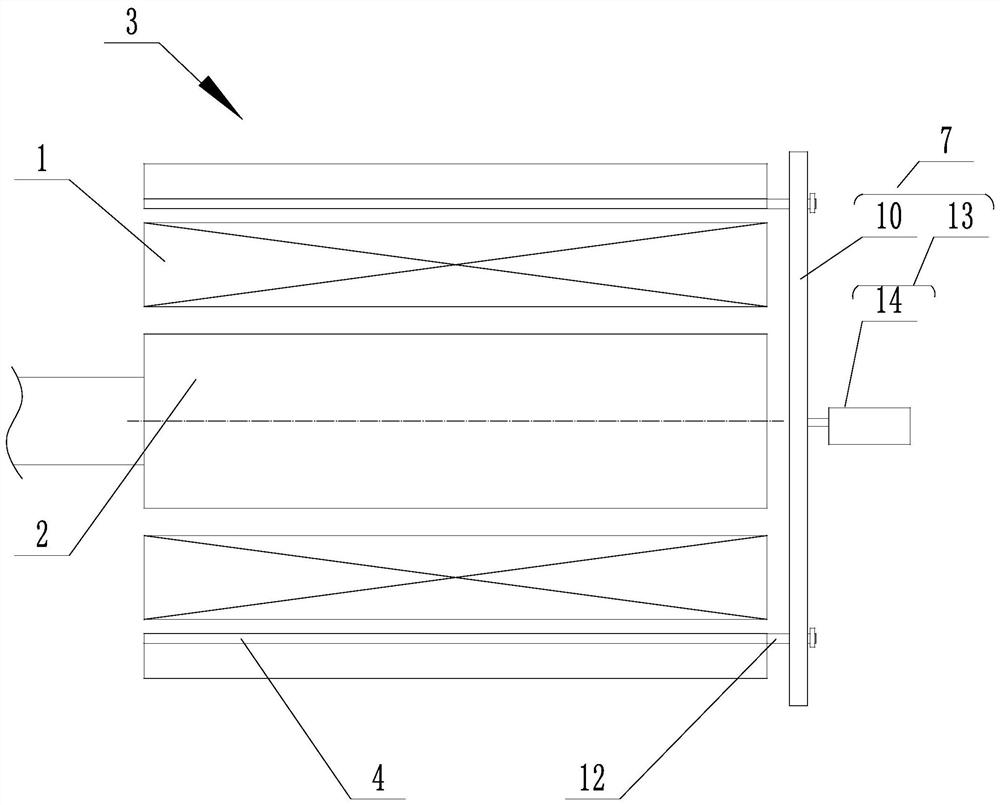

[0025] A motor for a range hood, such as figure 1 As shown, the motor has a stator 1 and a rotor 2 rotatably supported in the stator 1. The stator 1 is provided with a magnetic conductive component 3, and the magnetic conductive component 3 can deform to change the motor constant of the motor. The coils are arranged radially on the stator 1 . Permanent magnets are arranged radially on the rotor 2 .

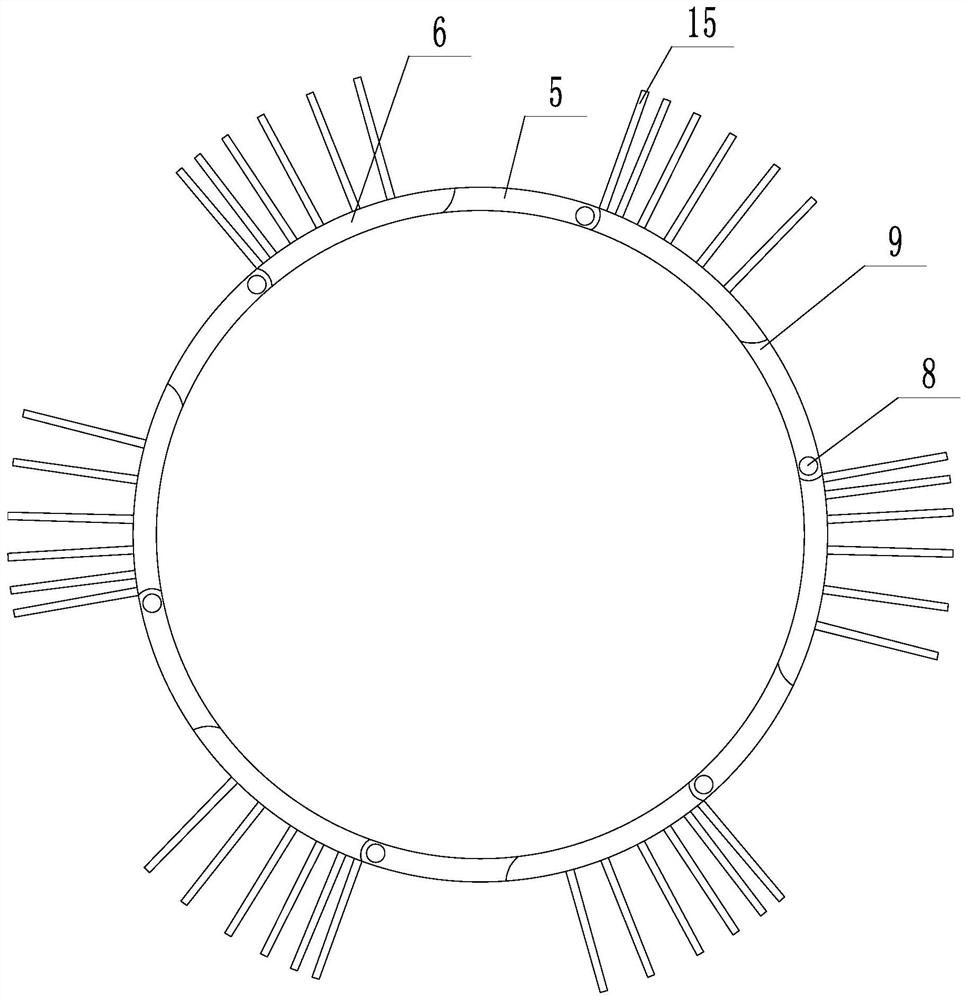

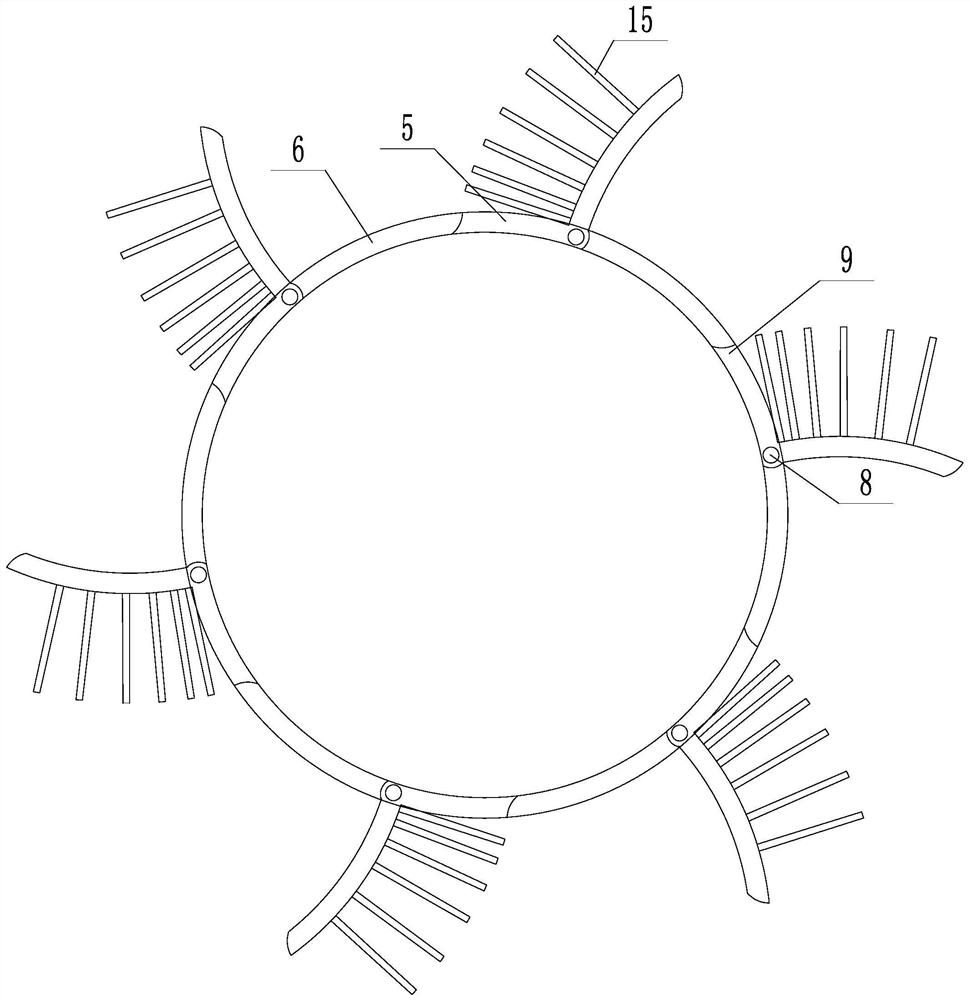

[0026] like figure 2 , 3 As shown, the deformation of the magnetically permeable component 3 can change the leakage flux, thereby changing the motor constant, taking into account both high torque and high rotational speed. The magnetic conductive assembly 3 includes a magnetic conductive cylinder 4 that surrounds the stator 1 and is coaxial with the stator 1. The magnetic conductive cylinder 4 includes a number of very narrow supporting pieces 5 arranged along the axial direction of the motor, and the supporting pieces 5 surround the magnetic conductive The cylinder 4 is arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap