Synergy methane for metal welding

A methane, welding and cutting technology, applied in the field of gas products for metal welding and cutting, can solve the problems of unsatisfactory cutting effect, low welding quality, low work efficiency, etc., reduce cleaning workload and post-processing procedures, increase cutting speed, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The product components and volume ratios of this embodiment are: 75% methane, 12% liquefied natural gas, 10% carbon tetrachloride, and 3% moisture.

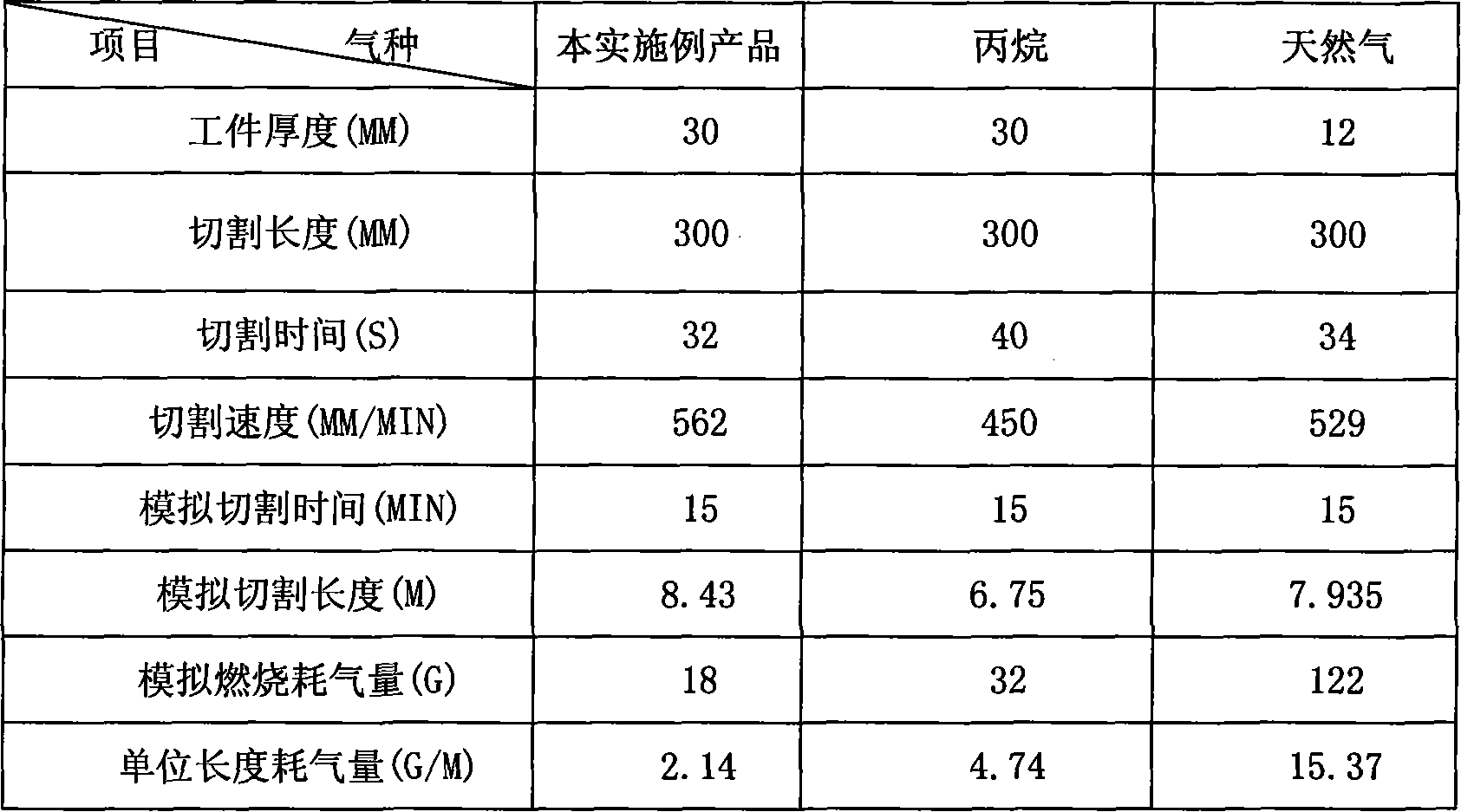

[0018] The main technical performance comparison between the product of this embodiment and the existing propane and natural gas welding gas is shown in the table below.

[0019] Comparison table of the main technical performance of the product in this example and the existing propane and natural gas welding gas

[0020]

[0021] It can be seen from the above table that the performances of the products of the embodiments of the present invention are better than those of the existing propane and natural gas welding gas products.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap