Plastic particle recycling and cleaning device

A cleaning device and technology for plastic granules, which are used in the drying of granular materials, the arrangement of drying gas, cleaning methods and utensils, etc., can solve the problems of granules easily contaminated with dust, complicated unloading process, waste of manpower and material resources, etc., and achieve convenient delivery and recycling. , reduce re-pollution, reduce the effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

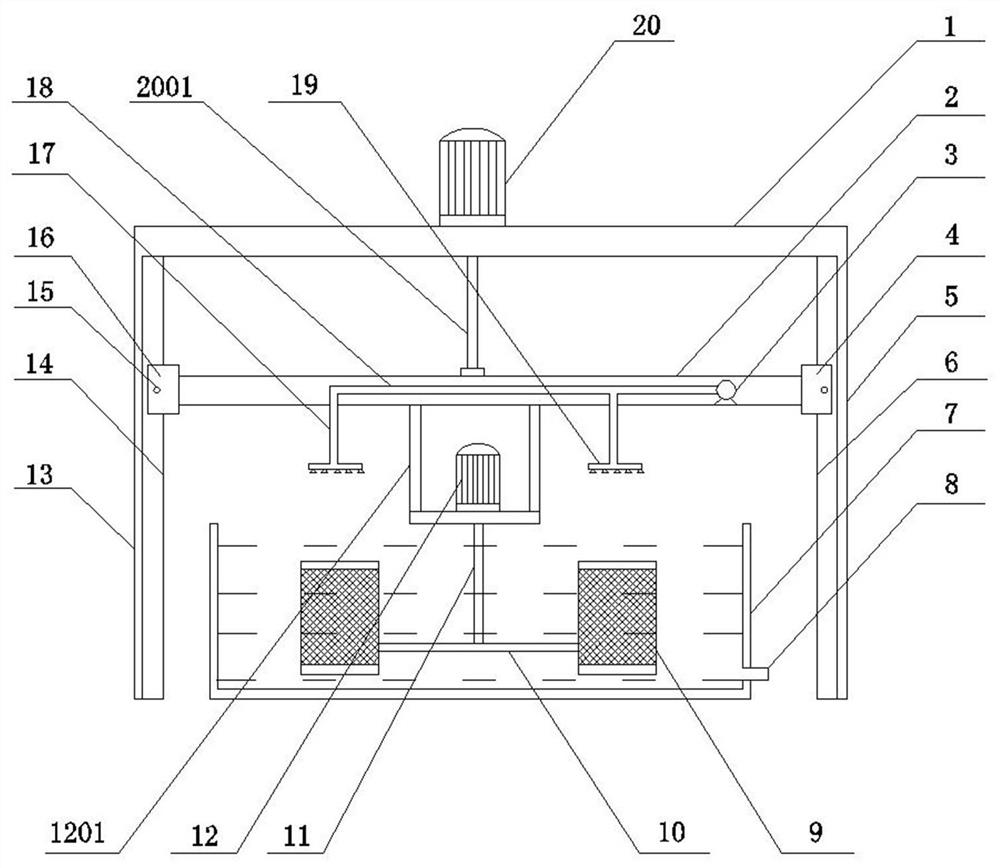

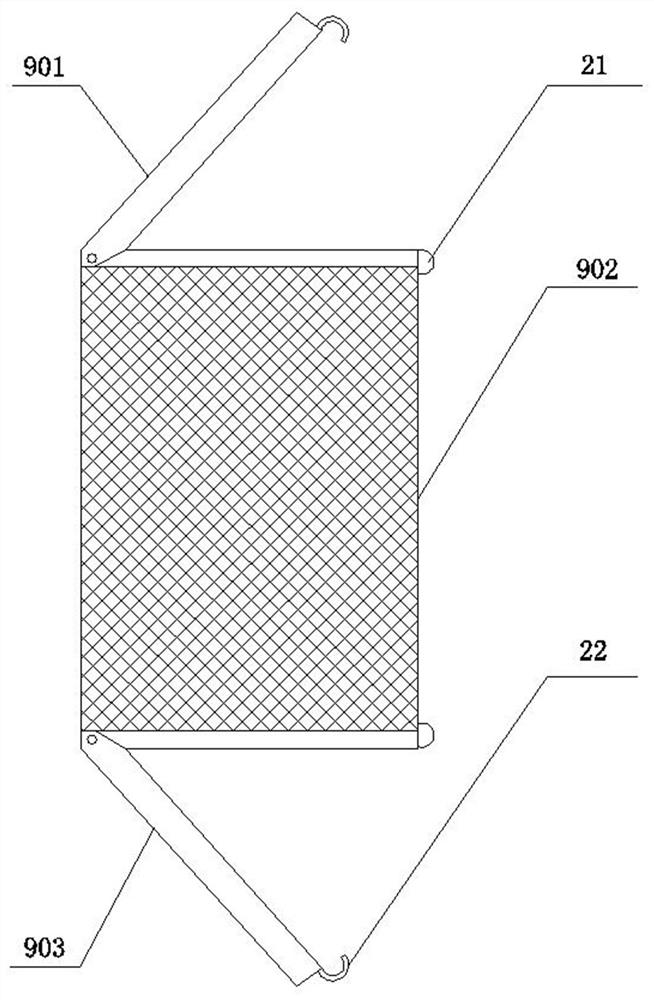

[0021] see Figure 1-2 , a kind of plastic granule recovery cleaning device, comprises support frame, cleaning tank 7 and cleaning mesh basket 9, and described support frame comprises first support column 5, second support column 13 and is fixedly connected on first support column 5, second The transverse support plate 1 at the top of the support column 13 .

[0022] The first support column 5 is provided with the first slide rail 6 along the cylinder direction, and the second support column 13 is oppositely provided with the second slide rail 14, the first slide block 4 is slidably installed on the first slide rail 6, the second A second slider 16 is slidably installed on the slide rail 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com