A simulation welding work frame and method for boiler water-cooled wall tubes for training

A water-cooled wall tube and work frame technology, which is applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of differences in welding operations, low qualification rate, and large number of tubes, so as to improve welding work efficiency and reduce welding seam digging and repairing. The number of times, the effect of improving the operation proficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

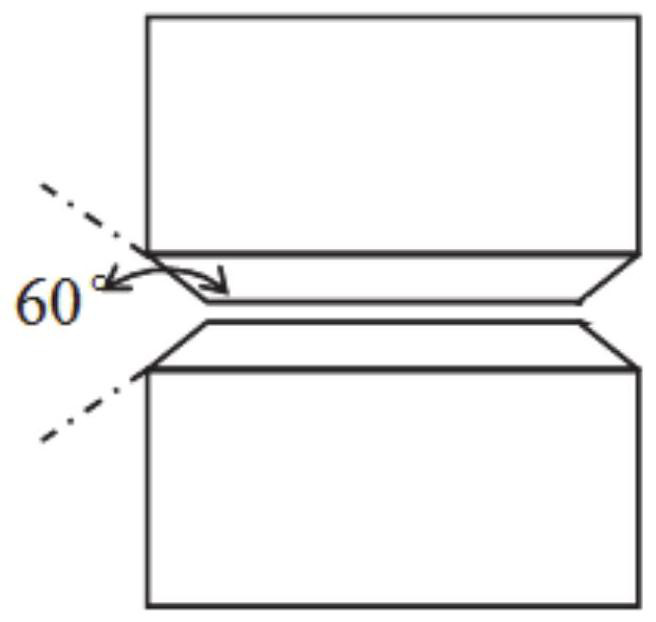

[0047] In a typical embodiment of the present disclosure, such as Figure 1-Figure 11 As shown, a training work frame for simulated welding of boiler water wall tubes is proposed.

[0048] The working frame includes a frame, a pipe row structure 2 and a rotating pair 3. The pipe row structure includes a plurality of branch pipes arranged at intervals in sequence. The first branch pipe and the last branch pipe of the pipe row structure are respectively connected to the frame through the rotating pair. In the branch pipe between the root and the last branch pipe, at least one branch pipe is cut, the cut branch pipe forms two sections arranged at intervals, and the end of the branch pipe corresponding to the cutting position is provided with a clamp;

[0049] Build a work frame dedicated to the simulated welding of water-cooled wall pipes, which can adjust the angle of the position to be operated, and set the cutting position to arrange fixtures to clamp the butt pipe to simulate...

Embodiment 2

[0071] In another exemplary embodiment of the present disclosure, as Figure 1-Figure 11 As shown, a simulation welding method of boiler water wall for training is proposed. The welding method adopts the combined welding method of manual tungsten argon arc welding bottom electrode arc welding to fill the cover surface. According to the relevant assessment regulations, the combined welding can replace the single The manual tungsten argon arc welding and electrode arc welding can learn two kinds of welding operations. After one pass, the qualification certificate of the two welding operations can be obtained, so that after the combined welding assessment, the welding skills of the welder can be applied in a wider range. , which saves costs for welder certification.

[0072] Use the training boiler water wall tube as described in Example 1 to simulate a welding work frame, including the following steps:

[0073] Adjust the relative position of the pipe row structure and the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com