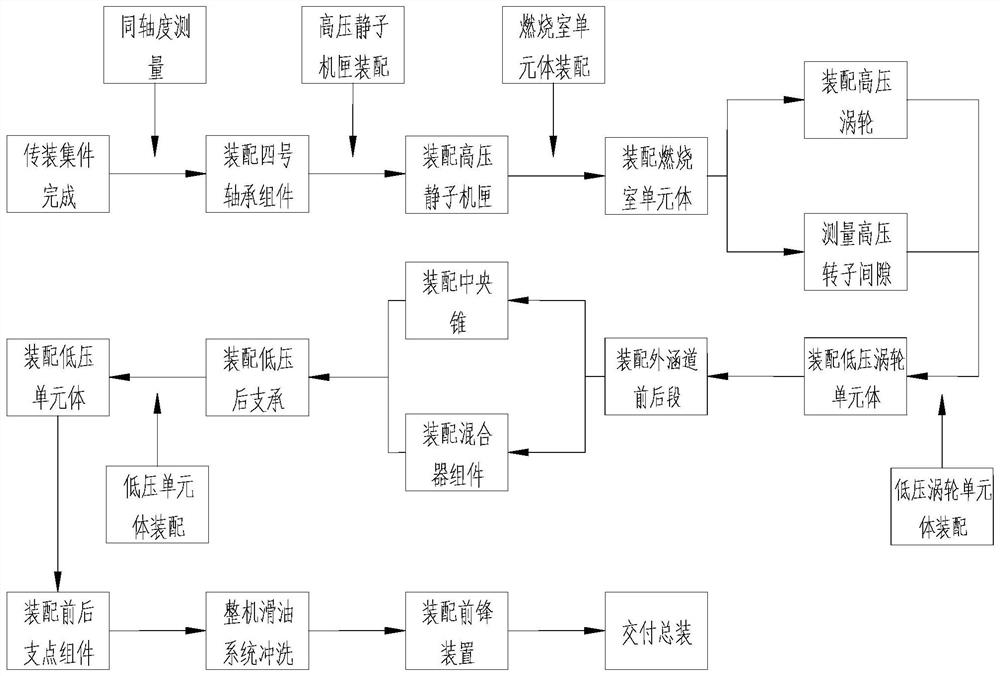

Optimization method for pulsating assembly line of small bypass ratio aeroengine

An aero-engine and optimization method technology, applied in the direction of assembly machines, aircraft parts, transportation and packaging, etc., can solve the problems of messy design and management of process layout, affect the continuity of aviation equipment supply, and fail to form production operation methods, etc., to achieve Realize the effects of refined management and operation, improvement of labor utilization rate, and clear quality responsibility subject

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Carry out the assembly of small bypass ratio aero-engines according to the technological process in the above content, record the working time of each pulsating station, take the first day after the technological process is optimized as the recording starting point, and take the 12-day general assembly process as a recording cycle ;Taking station No. 2 as an example, the daily working hours are 195 minutes, 190 minutes, 185 minutes, 185 minutes, 180 minutes, 175 minutes, 170 minutes, 175 minutes, 165 minutes, 165 minutes, 160 minutes, 160 minutes . During the operation, it was found that the working time of each station showed a downward trend and gradually stabilized over time. The main reason is that the process content in each station is simpler than the traditional assembly mode, and the operation difficulty is reduced. Familiarity with the work content of the station increases the proficiency of the operation rapidly; and the working time of each station exceeds th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com