Stacker and operating method thereof

A technology of stacker and car body, which is applied to the direction of steering control, control device, and vehicle parts installed on the car, and can solve the problems affecting the stability and reliability of the stacker, the unilateral bending deformation of the lifting mast, and the impact To solve problems such as the working efficiency of the stacker, achieve the effect of convenient and efficient operation, reduce work intensity and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

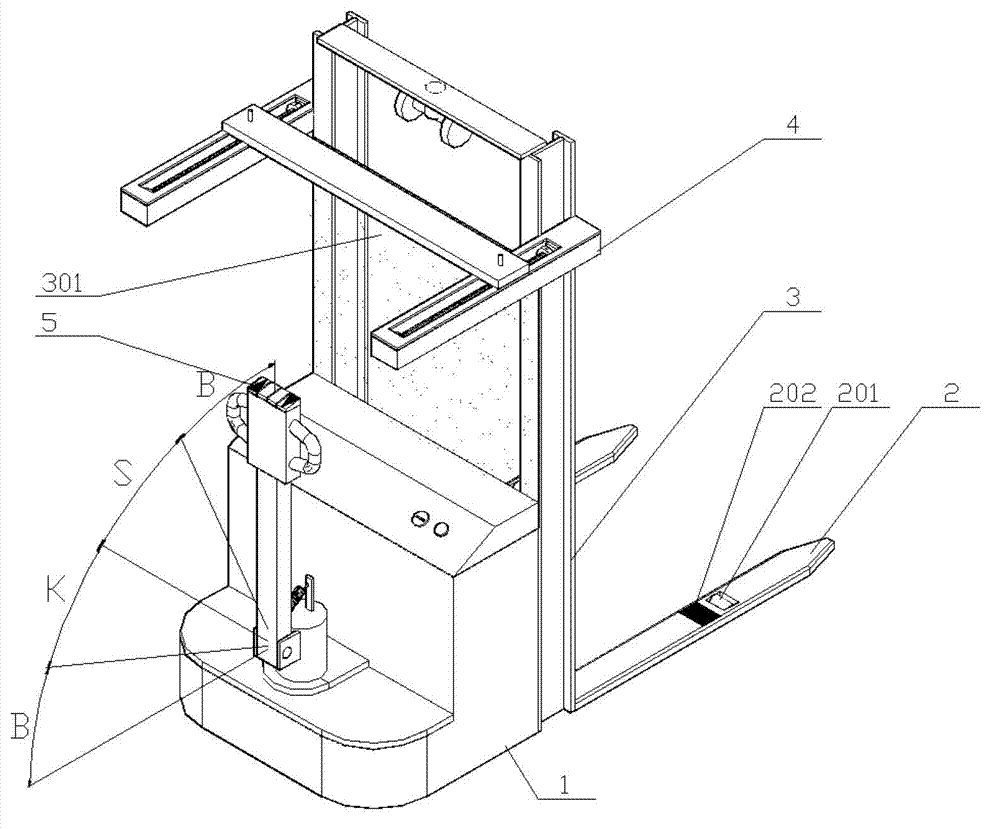

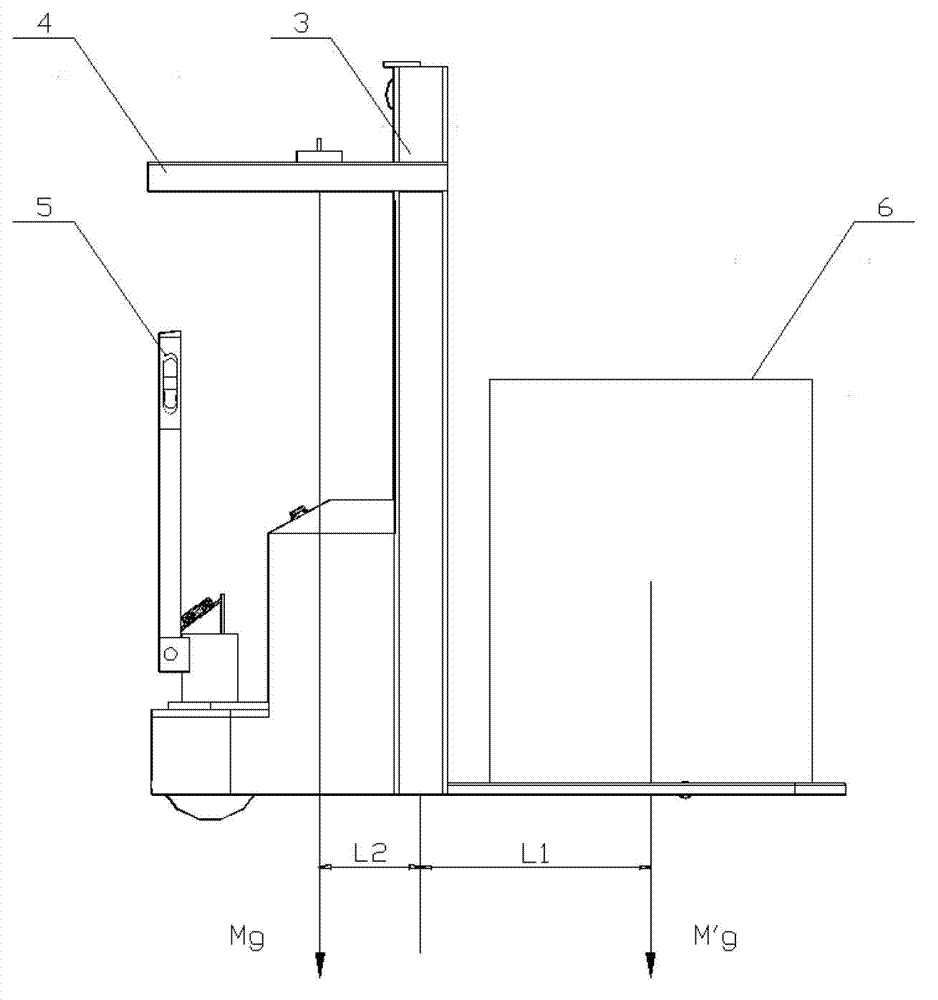

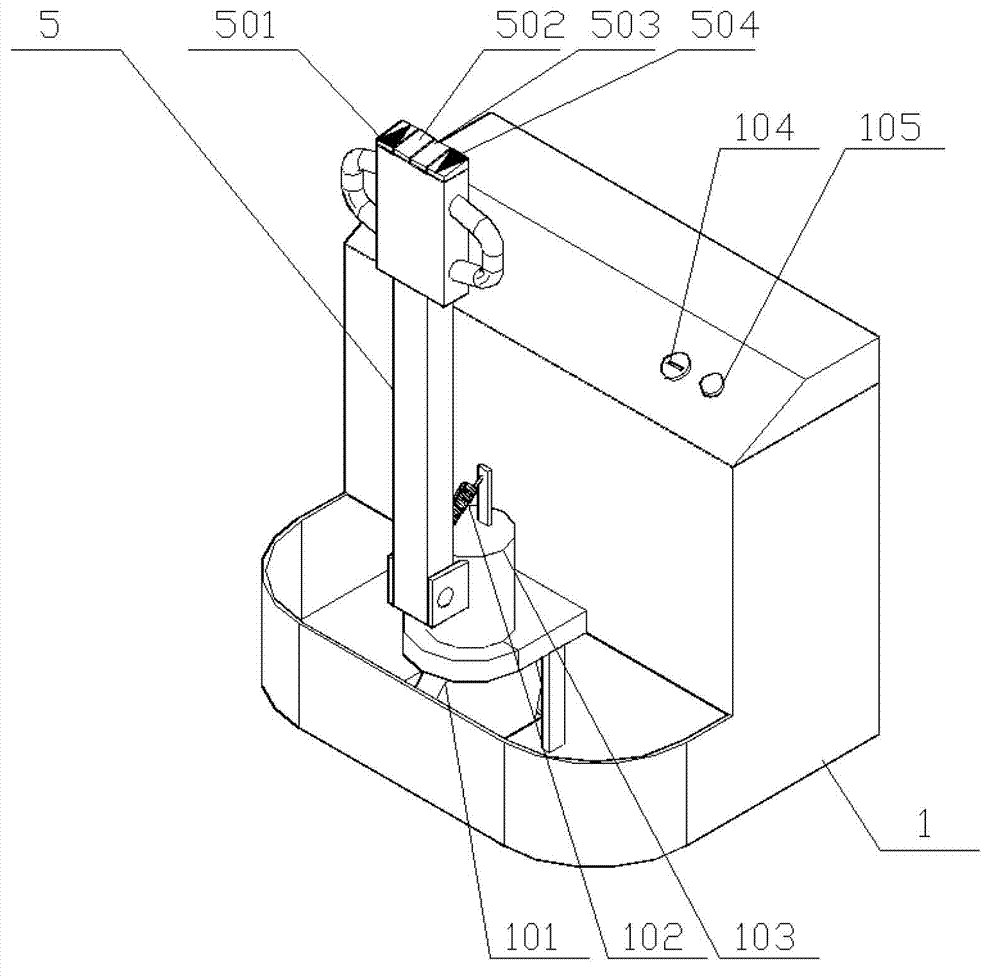

[0038] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it shows an embodiment of the present invention, the stacker of the present invention and its control method. The stacker includes a car body 1, forks 2, a lifting mast 3, and a A battery, a motor for driving the car body 1 and a gearbox for changing the transmission ratio of the motor; the lifting mast 3 is arranged on the front side of the car body 1, and the lifting mast 3 is composed of a liftable inner frame and a fixedly installed outer frame. Fork legs 2 are installed on the inner frame that can be lifted; the bottom of the car body 1 is equipped with driving wheels 101 that drive the car body to travel and turn; technology also includes figure 1 The fork caster wheel 201 that is installed on the shown fork foot 2 supports and assists rolling, and the balance wheel ( not shown).

[0039] Above-mentioned driving wheel 101 comprises the rotating shaft 103 of adjusting wheel steering and the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com