An assembly and disassembly device for the compression nut of the inner ring of the bearing

A technology of bearing inner ring and compression nut, which is applied in workpiece clamping devices, metal processing equipment, metal processing and other directions to simplify the assembly and disassembly process and improve operational safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

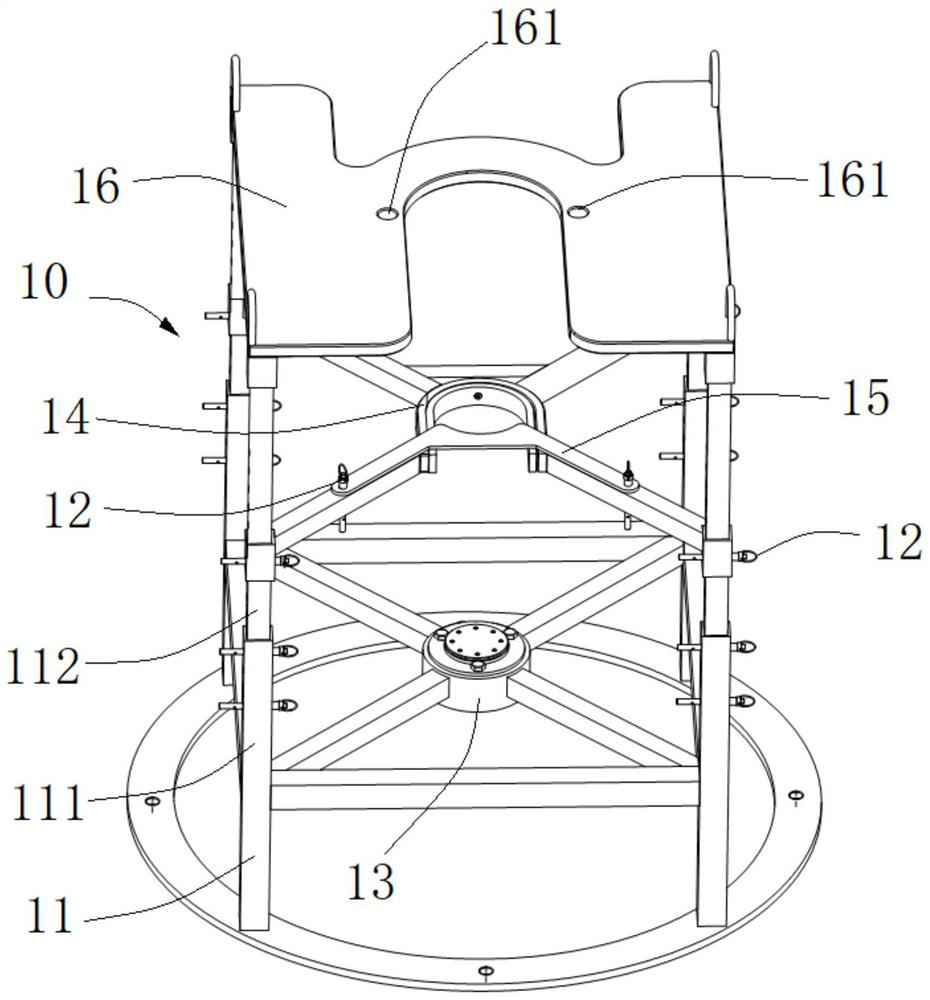

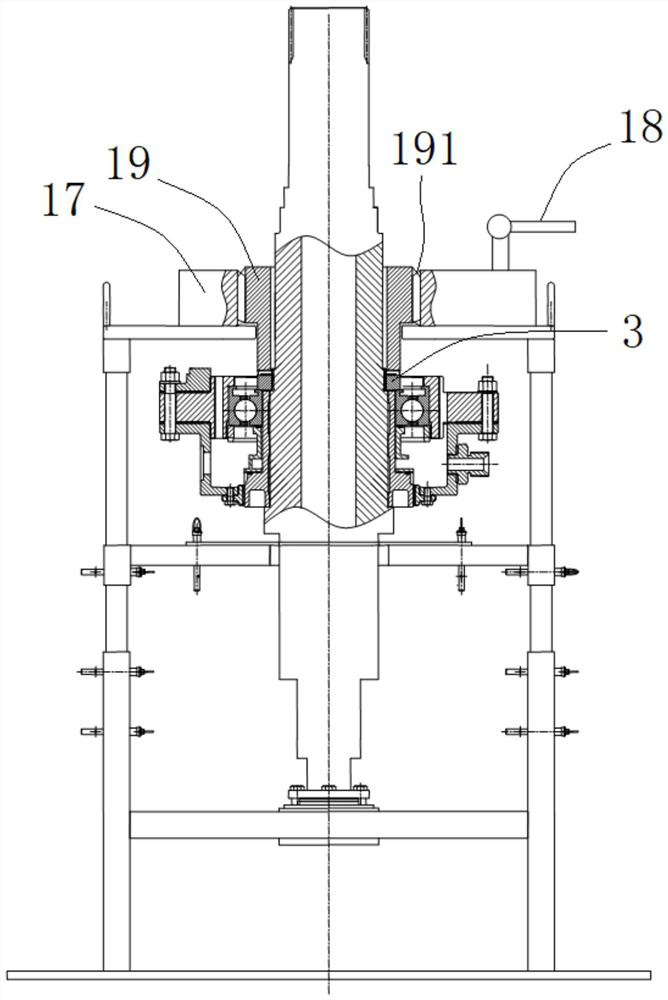

[0038] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

[0039] In order to overcome the problems of difficult assembly and disassembly process and low operation safety of the compression nut of the inner ring of the aero-engine bearing in the prior art, the present application provides a device that can be used for the assembly and disassembly of the compression nut of the inner ring of the bearing, thereby simplifying the Compression nut assembly and disassembly process, while improving operational safety.

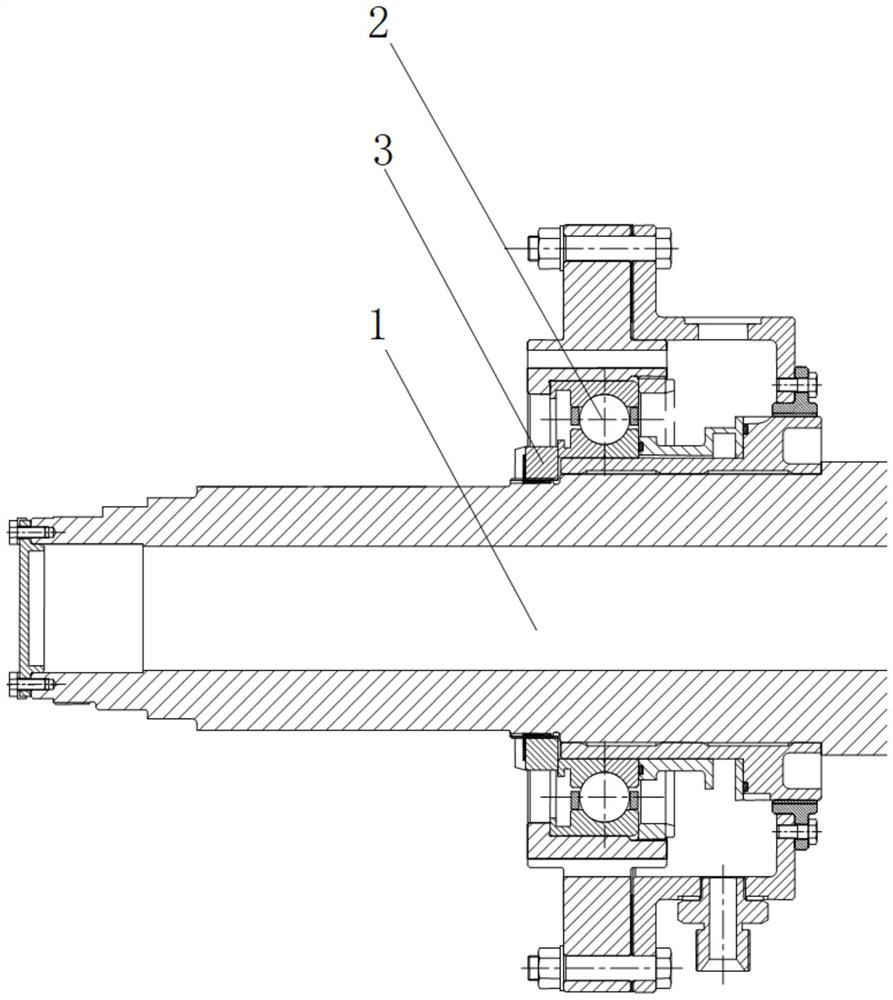

[0040] like figure 2 and image 3 As shown, the device provided in this application mainly includes: a main support 11 , a fixing table 13 , an operation table 16 , a lifting fixture 14 , a pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com