Chain saw

A chain saw and chain technology, which is applied in the field of chain saws, can solve the problems of loose chain, narrow application range, and large number of parts of the fastening device, and achieve the effects of avoiding loss, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be further described in detail below with reference to the drawings and embodiments.

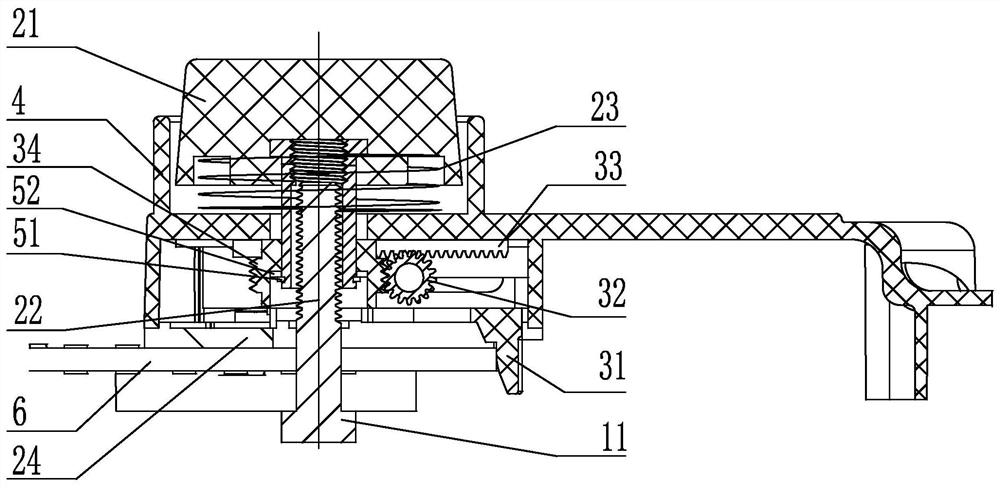

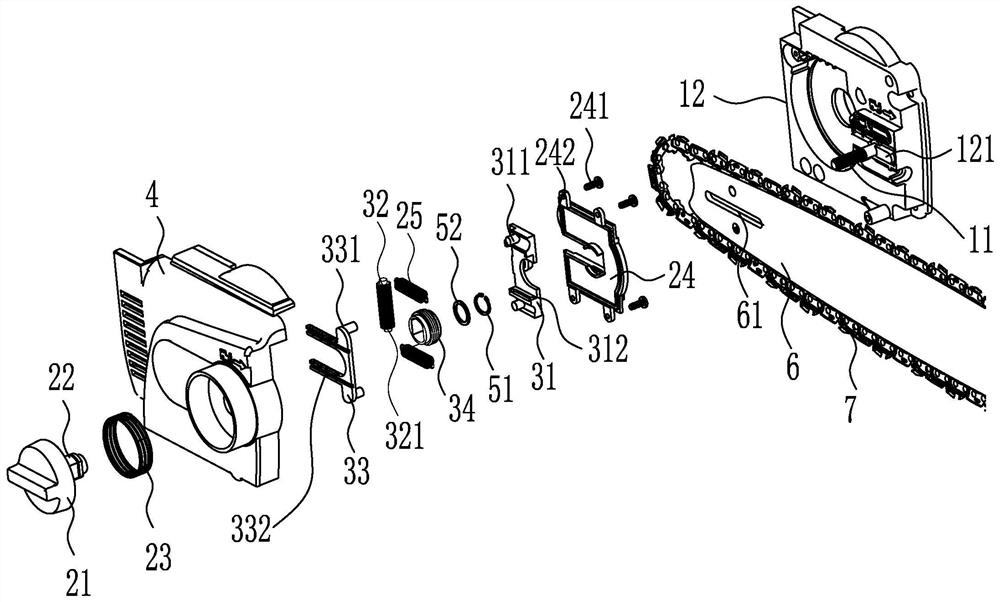

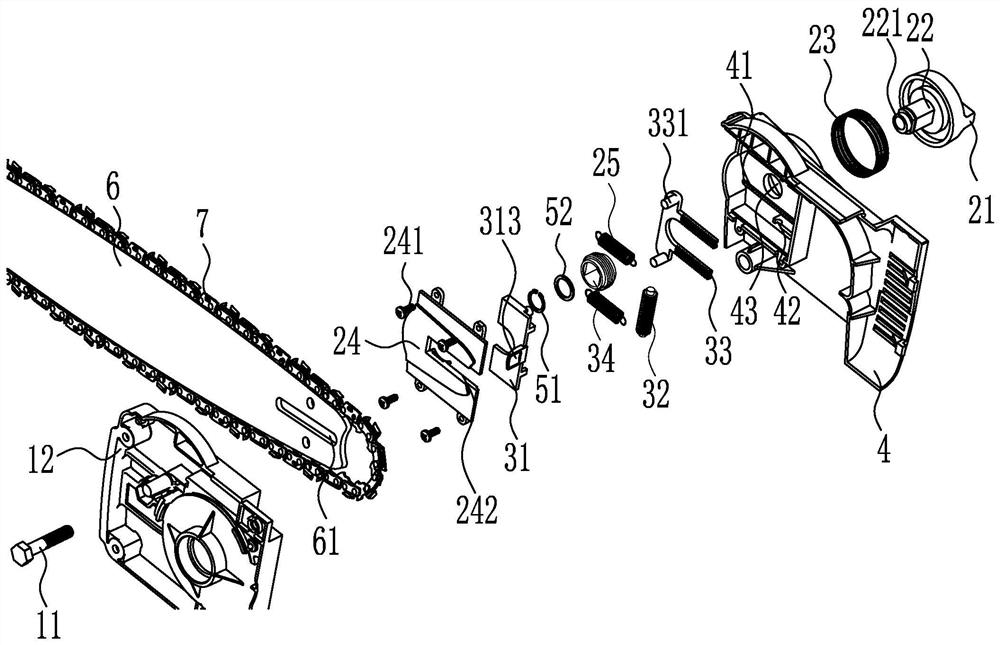

[0024]Such asFigure 1-Figure 4Shown is a chain saw involved in an embodiment of the present invention, please refer toFigure 4 The chain saw includes a main body 100, a chain 7, and a guide plate 6 that guides the chain 7. The main body 100 includes a sprocket that drives the chain 7 to rotate and cut along the edge of the guide plate 6, and the guide plate 6 forwards Extending the main body 100 and being able to move back and forth relative to the main body 100 in an unfixed state, the guide plate 6 is fixed on the guide plate fixing plate 12 provided on one side of the main body 100, and the guide plate is fixed The side of the plate 12 facing the guide plate 6 is provided with a convex portion 121, and the guide plate 6 is correspondingly provided with a stroke groove 61. The convex portion 121 passes through the stroke groove 61 and restricts the guide plate 6 alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com