Unconventional condensate gas reservoir fluid replacement and flow state control downhole sampling method

A kind of condensate gas reservoir, unconventional technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of non-condensate gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

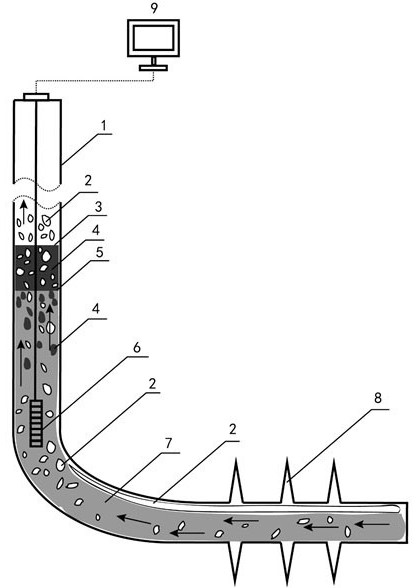

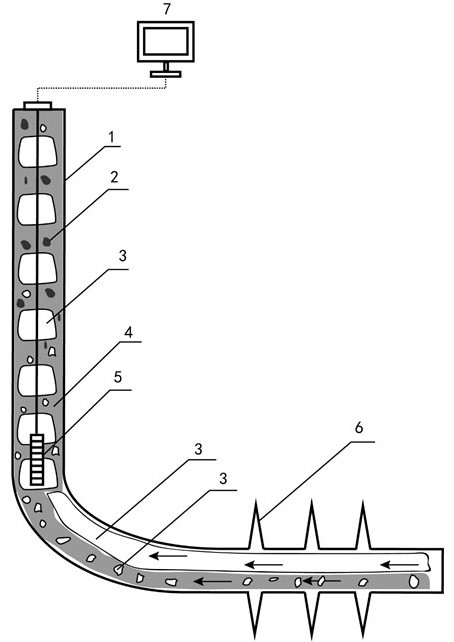

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

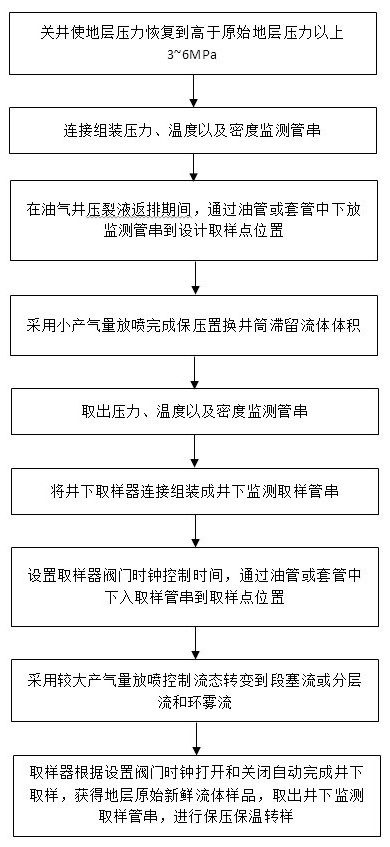

[0030] Such as figure 1 As shown, an unconventional gas condensate reservoir fluid displacement and flow state control downhole sampling method includes the following steps:

[0031] S1: After the perforation-washing-fracturing operation is completed in the target condensate gas reservoir, the well is shut down to restore the formation pressure to 3-6 MPa higher than the original formation pressure;

[0032] S2: Connect and assemble pressure, temperature and density monitoring pipe strings;

[0033] S3: During the flowback of fracturing fluid in oil and gas wells, lower the monitoring string to the designed sampling point through the tubing or casing, and test the temperature and pressure gradient of the wellbore at the same time;

[0034] S4: Use small gas production to release and blow out to complete the pressure maintenance and replacement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com