Embedded firmware remote debugging method and system

A remote debugging and embedded technology, which is applied in software testing/debugging, instrumentation, electrical digital data processing, etc., can solve problems such as low efficiency and inconvenient code modification, and achieve the effect of easy positioning of problems and simplification of debugging links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

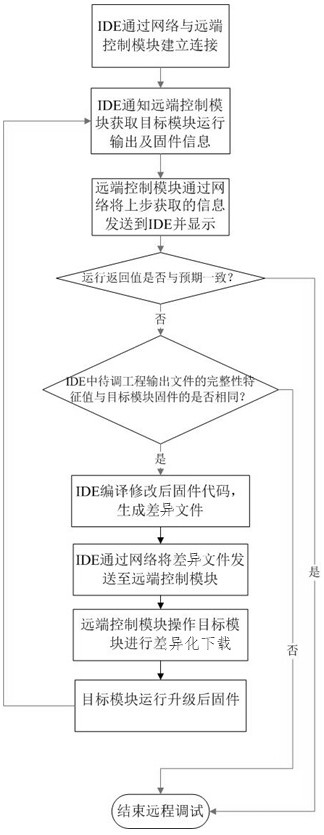

Image

Examples

Embodiment 1

[0024] An embedded firmware remote debugging system, including IDE (MounRiver Studio) and a remote control module,

[0025] The IDE is used to send instructions, receive and display the target module operation output results, receive code modification and generate a differential download file according to the code before and after modification, and the differential download file includes code modification address and modification content;

[0026] The remote control module includes a main control unit, a network unit and a burning unit, and the network unit and the burning unit are all connected to the main control unit; the burning unit is used for burning the target module; the main control unit, the network unit and the burning unit The unit is integrated in a circuit board module.

[0027] The IDE is connected to the network unit of the remote control module through the network. This embodiment uses a 4G network, and other networks can also be used. The programming unit o...

Embodiment 2

[0034] Compared with Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that the remote control module can also implement the control function by installing a customized APP on the smart terminal, that is, the main control unit is installed on the smart terminal (mobile phone, tablet computer, computer or embedded Since the smart terminal itself has its own network unit, there is no need to set up another network unit, and you can directly use the network function of the smart terminal. The communication between the smart terminal and the target module adopts BLE and serial port, or BLE and USB port to read the information of the target module and burn the target module. Except for this, other contents are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com