One-dimensional and three-dimensional joint simulation method for automobile engine cooling system

An automotive engine and cooling system technology, applied in design optimization/simulation, computer-aided design, image data processing, etc., can solve problems such as large errors in water temperature simulation results, inability to accurately evaluate the cooling system water temperature, and difficulty in ensuring simulation accuracy. The effect of reducing simulation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] An embodiment of the present invention provides a one-dimensional and three-dimensional co-simulation method for an automobile engine cooling system, comprising the following steps:

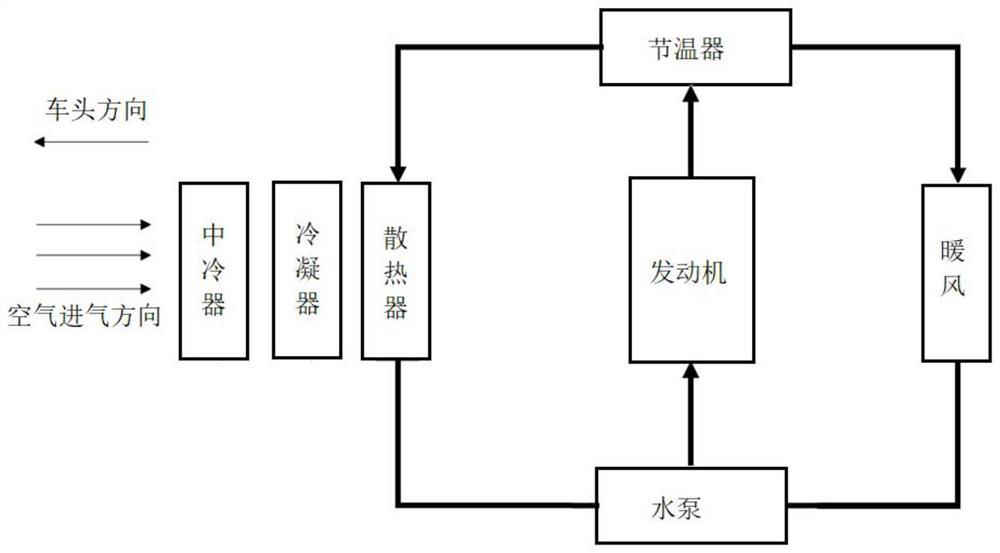

[0016] S101. Use 3D simulation software to analyze the steady-state thermal flow field, and estimate the thermal power Q of the radiator and intercooler rad0 , Q cac0 , the thermal power of the condenser takes a constant value Q con , and then get the outlet air volume q of radiator, intercooler and condenser core rad1 ,q cac1 ,q con1 , and the average surface temperature T at the core inlet rad1 , T cac1 , T con1 ;

[0017] S102, based on q rad1 ,q cac1 ,q con1 and T rad1 , T cac1 , T con1 , use one-dimensional simulation software to carry out one-dimensional system simulation calculation, and get the thermal power of radiator and intercooler as Q rad1 , Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com