A multifunctional wire tensioner for power transmission and transformation lines

A multi-functional technology for power transmission and transformation lines, applied in the field of auxiliary equipment for power facilities, can solve problems such as time-consuming, inefficient, and cumbersome, and achieve the effects of reducing costs, simplifying structures, and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

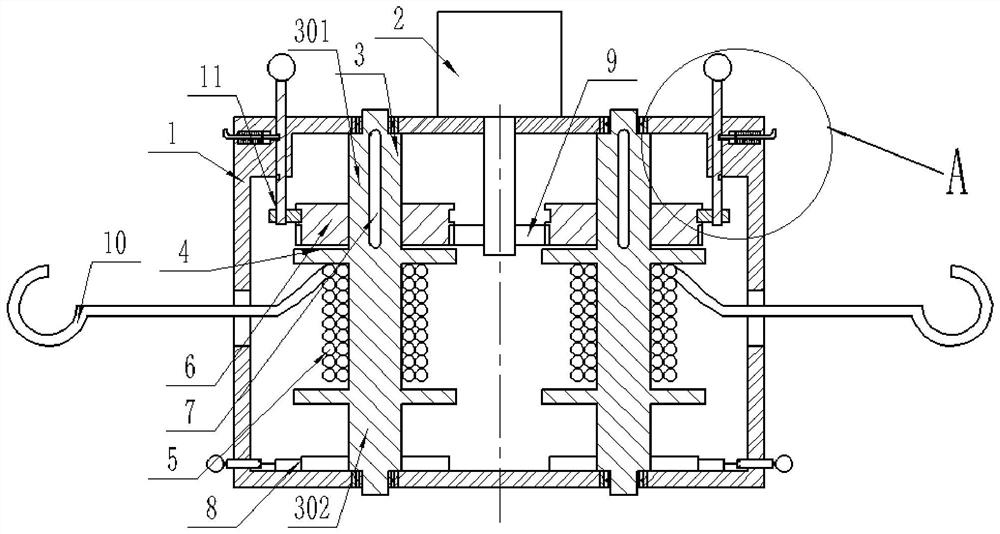

[0018] see Figure 1-Figure 3 , a multifunctional wire tensioner for power transmission and transformation lines, including a housing 1 and a geared motor 2, two groups of wire tensioning devices are symmetrically arranged in the housing, and the wire tightening devices include a rotating shaft 3, and the two ends of the rotating shaft pass through The bearing is connected to the housing in rotation; two annular disks 4 are fixedly arranged in the middle of the rotating shaft in the circumferential direction. The shaft is the upper rotating shaft 301, and the rotating shaft at the bottom of the reel is the lower rotating shaft 302;

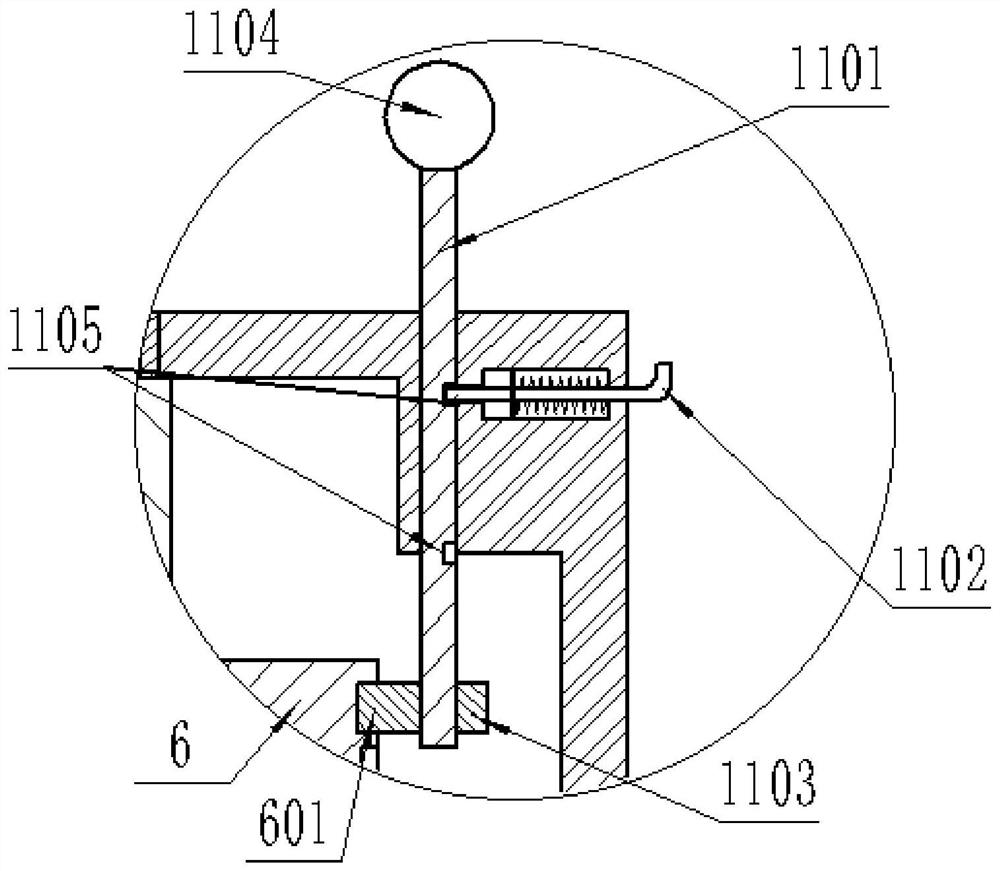

[0019] A driven gear 6 is arranged on the upper rotating shaft close to the reel, and the driven gear and the upper rotating shaft are connected by a guide key 7;

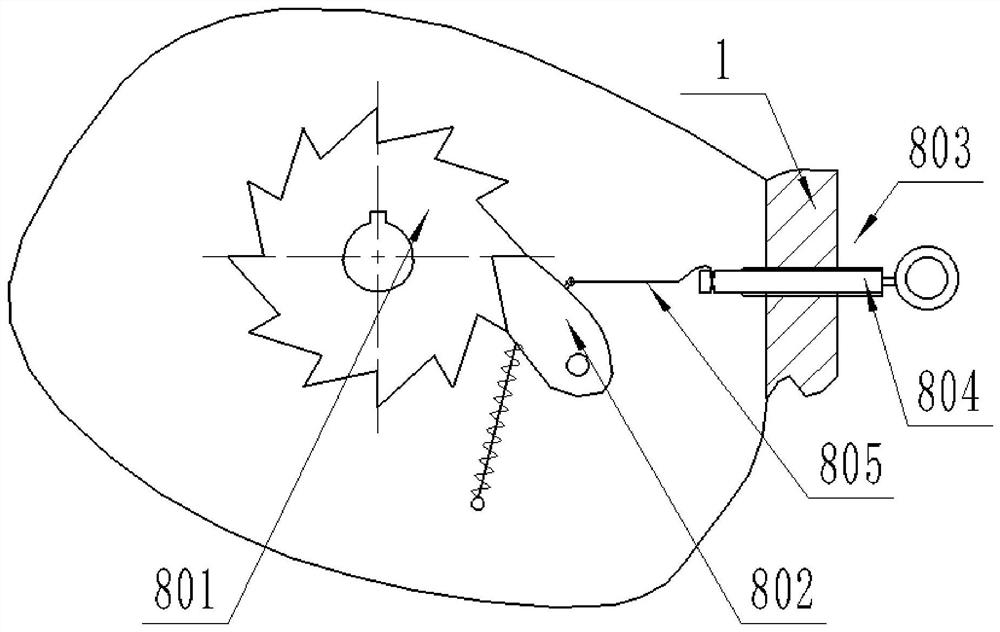

[0020] An anti-reversal mechanism 8 for preventing the reverse rotation of the rotating shaft is fixedly arranged on the lower rotating shaft near the housing wall;

[0021] The gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com