Cold laminating machine

A film machine and cold sleeve technology, which is applied in the direction of packaging/bundling items, external support, packaging, etc., can solve the problems of unable to seal the packaging film and cannot realize sealed packaging, etc., to achieve stable work, continuous filming, and avoid pads Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

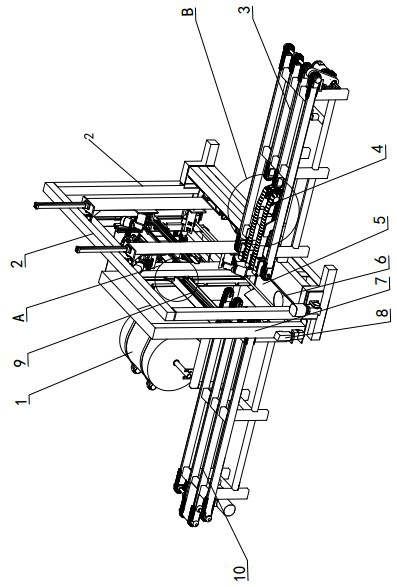

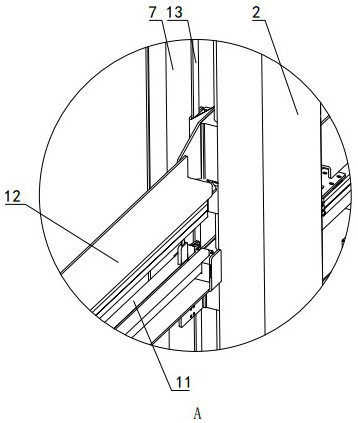

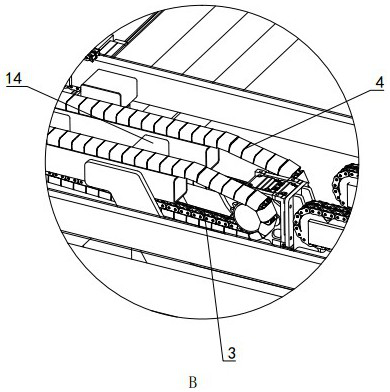

[0036] Figure 1~10 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~10 The present invention will be further described.

[0037] A cold film machine, comprising a film supply device 1, a film device 2 and a conveying device, the film device 2 is arranged on the packaging film output side of the film supply device 1, and the film device 2 is connected to push it between the conveying device and the supply device. The pushing device that reciprocates between the film devices 1, the conveying device is provided with a relief part that cooperates with the film device 2, and is set on the output side of the packaging film of the film supply device 1 and between the conveying device and the film device 2 A heat-sealing film cutting device 9 is arranged. The film feeding device 1 of this cold film machine transports the stretched packaging film to the film covering device 2 for temporary storage, and then the film covering device 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com