Dust removal device for rubber-plastic cable processing

A technology of dust removal device and cable, which is applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of high height, inconvenient replacement, poor fixed structure of filter bags, inconvenient dust removal, etc., so as to improve the dust removal effect and facilitate the Replace and clean, improve the effect of fixed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

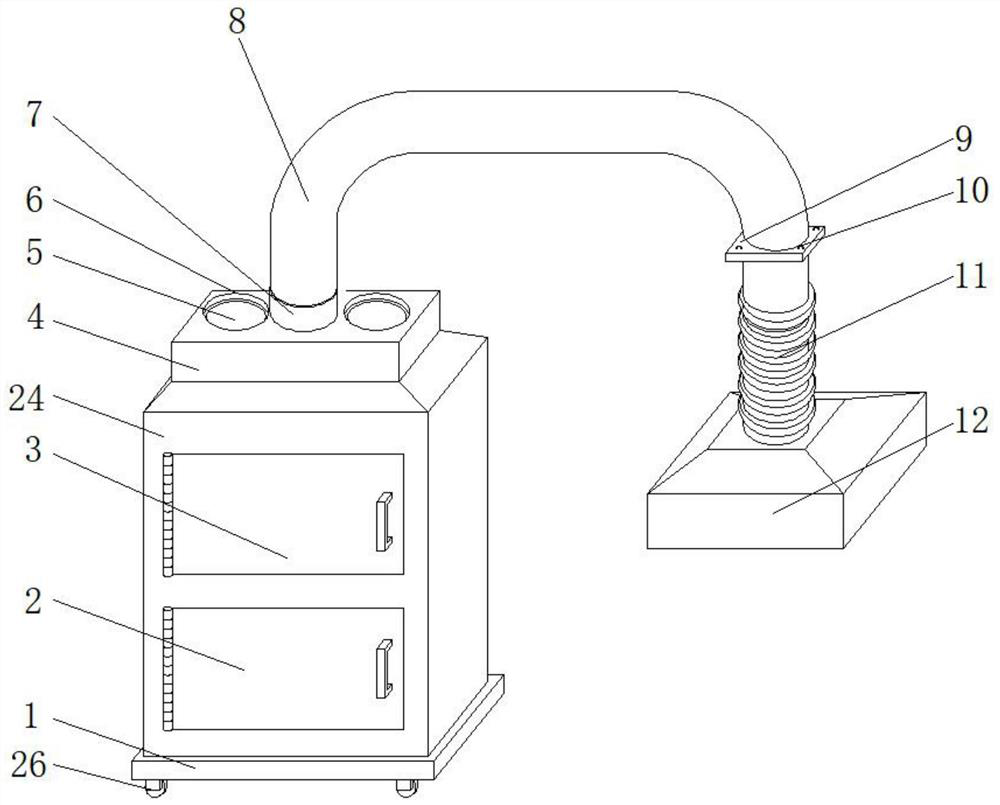

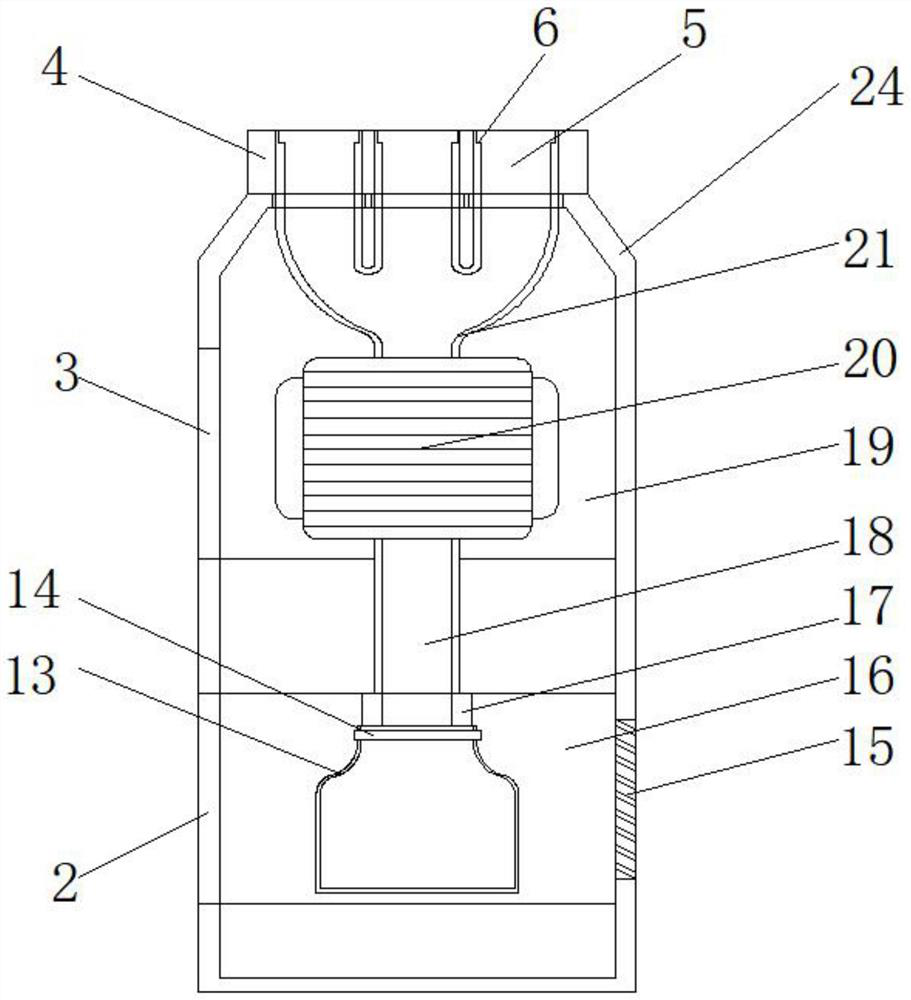

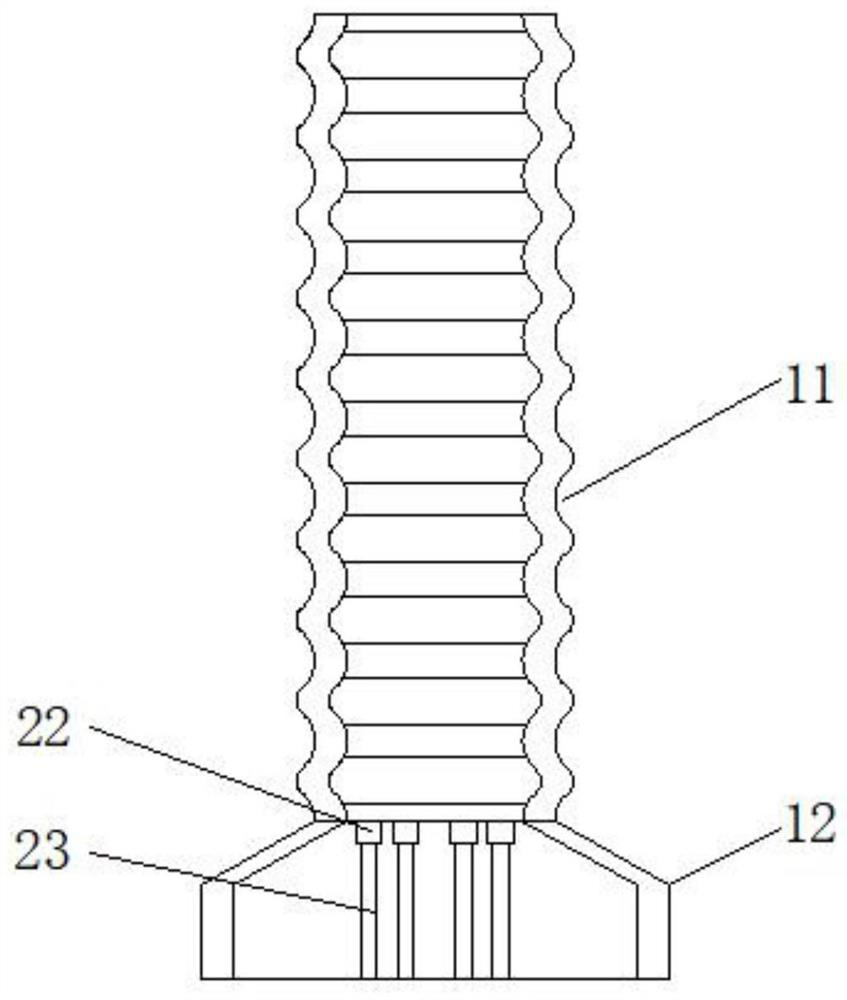

[0028] For specific embodiment 1, please refer to Figure 1-5 , the present invention provides a technical solution: a dust removal device for rubber-plastic cable processing, comprising a frame 24, characterized in that: the inner bottom of the frame 24 is excavated with a first cavity 16, and the top of the frame 24 is excavated with a second cavity 16. cavity 19;

[0029] The top of the frame 24 is integrally formed with a top frame 4, and the top frame 4 is equidistantly excavated with a top-to-bottom penetrating dust cavity 5, and a limit groove 6 is excavated in the dust cavity 5. The limit groove 6. A pipe joint 7 is fastened and fixed inside, the top of the pipe joint 7 is connected with a pipe 8, the other end of the pipe 8 is fixed with a fixed plate 9, and the bottom end of the fixed plate 9 is connected with a corrugated pipe 11. The corrugated pipe The bottom end of 11 is connected with a dust collecting bucket 12, and the top end of the first cavity 16 is connec...

specific Embodiment 2

[0031] see Figure 1-5 , the present invention provides a technical solution: a dust removal device for rubber-plastic cable processing, comprising a frame 24, characterized in that: the inner bottom of the frame 24 is excavated with a first cavity 16, and the top of the frame 24 is excavated with a second cavity 16. cavity 19;

[0032] The top of the frame 24 is integrally formed with a top frame 4, and the top frame 4 is equidistantly excavated with a top-to-bottom penetrating dust cavity 5, and a limit groove 6 is excavated in the dust cavity 5. The limit groove 6. A pipe joint 7 is fastened and fixed inside, the top of the pipe joint 7 is connected with a pipe 8, the other end of the pipe 8 is fixed with a fixed plate 9, and the bottom end of the fixed plate 9 is connected with a corrugated pipe 11. The corrugated pipe The bottom end of 11 is connected with a dust collecting bucket 12, and the top end of the first cavity 16 is connected with a dust removal pipe 17. The ou...

specific Embodiment 3

[0035] see Figure 1-5 , the present invention provides a technical solution: a dust removal device for rubber-plastic cable processing, comprising a frame 24, characterized in that: the inner bottom of the frame 24 is excavated with a first cavity 16, and the top of the frame 24 is excavated with a second cavity 16. cavity 19;

[0036] The top of the frame 24 is integrally formed with a top frame 4, and the top frame 4 is equidistantly excavated with a top-to-bottom penetrating dust cavity 5, and a limit groove 6 is excavated in the dust cavity 5. The limit groove 6. A pipe joint 7 is fastened and fixed inside, the top of the pipe joint 7 is connected with a pipe 8, the other end of the pipe 8 is fixed with a fixed plate 9, and the bottom end of the fixed plate 9 is connected with a corrugated pipe 11. The corrugated pipe The bottom end of 11 is connected with a dust collecting bucket 12, and the top end of the first cavity 16 is connected with a dust removal pipe 17. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com