Anti-loose clamping chuck structure

A technology of loose clamping and clamping, which is applied in the field of clamping structure of anti-loosening clamping, and can solve problems such as damage and collapse of the clamping clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to illustrate the central idea of the present invention in the column of the above-mentioned content of the invention, it is now expressed in specific embodiments. Various objects in the embodiments are drawn according to proportions, sizes, deformations or displacements suitable for illustration, rather than drawn according to the proportions of actual components, which are described first.

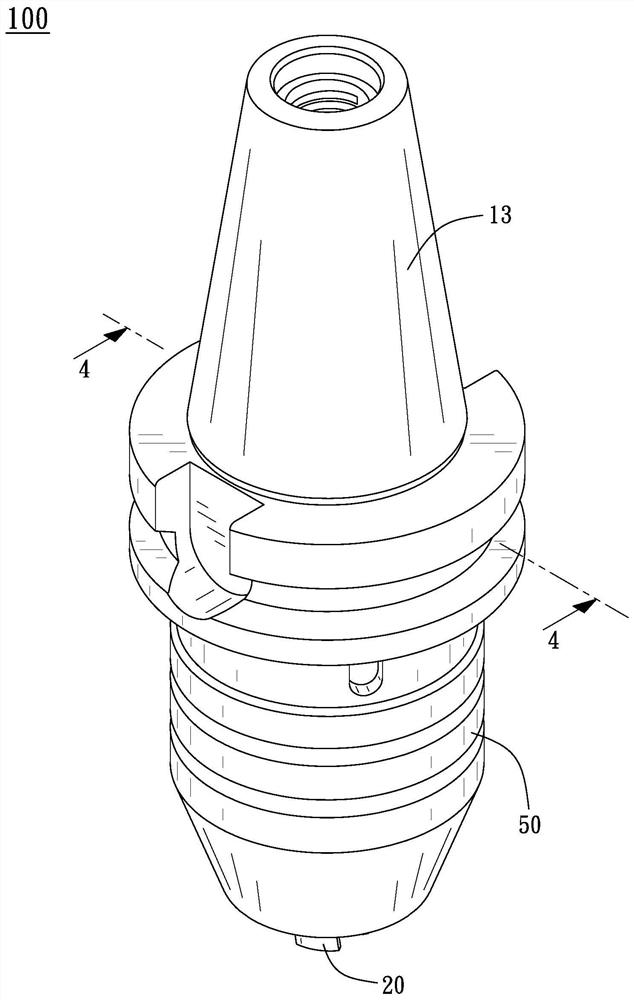

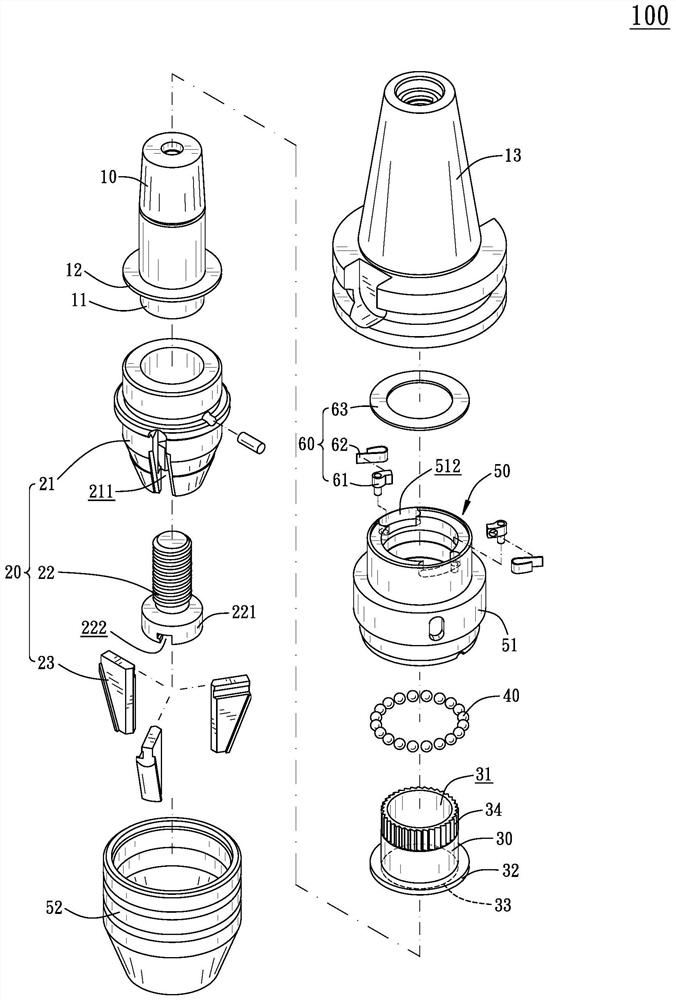

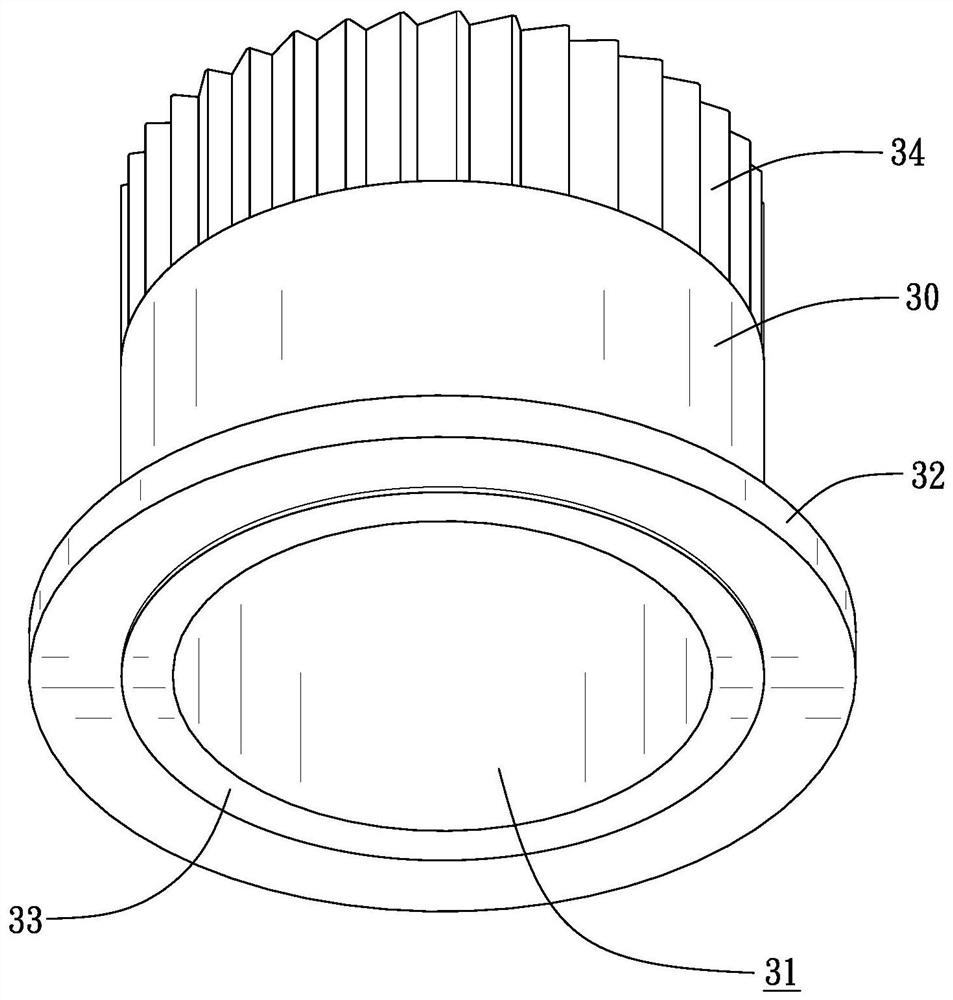

[0033] see Figure 1 to Figure 11 As shown, the present invention provides a chuck structure 100 for anti-loosening clamping, which includes a connecting shaft 10, a clamp 20, a damping member 30, a plurality of rollers 40, a pivot sleeve 50 and a one-way mechanism 60, of which:

[0034]The connecting shaft 10 has an end portion 11 and a first disc portion 12 adjacent to the end portion 11 , and the first disc portion 12 is arranged around the connecting shaft 10 in a radial direction. In this embodiment, the connecting shaft 10 is connected to a handle 13 at an end d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com