A Knitted Cloth Open Width Washing and Squeezing Device and Weaving Method

A technology for open-width washing and knitted fabrics, applied in the field of knitted fabric manufacturing, can solve problems such as poor washing effect, and achieve the effects of safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

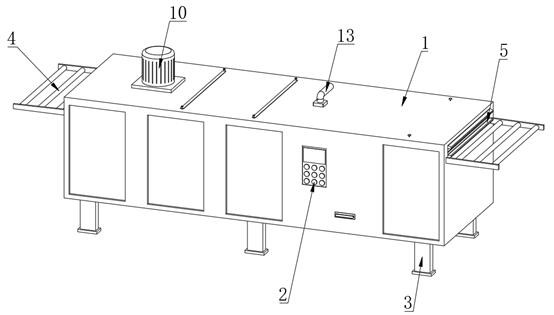

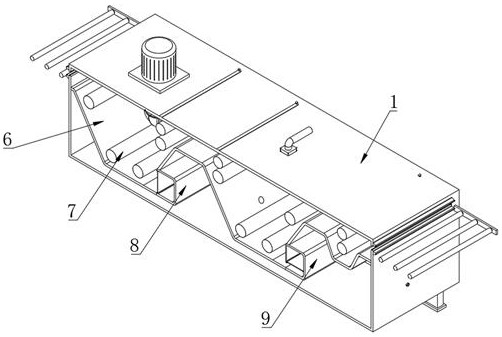

[0042] Embodiment 1: as Figure 1-7 As shown, the present invention provides a technical solution, a knitted fabric open-width washing and shrinking device, comprising a washing machine 1, one end of the washing machine 1 is embedded with a control switch 2, and the bottom of the washing machine 1 is evenly connected with a support column 3, The two ends of the washing machine box 1 are symmetrically equipped with cloth conduction rollers 4, and the two ends of the water washing machine box 1 are connected with a cloth conduction block 5 at the position below the cloth conduction roller 4. The inner wall of the water washing machine box 1 is connected with a washing chamber 6. A washing guide roller 7 is uniformly connected to the position above the inner wall corresponding to the washing chamber 6, an extraction chamber 8 is installed on the inner wall of the washing machine box 1 corresponding to one end of the washing chamber 6, and a drain is installed on the inner wall of ...

Embodiment 2

[0058] Embodiment 2: as Figure 1-7 As shown, the present invention provides a technical solution, a knitted fabric open-width washing and shrinking device, comprising a washing machine 1, one end of the washing machine 1 is embedded with a control switch 2, and the bottom of the washing machine 1 is evenly connected with a support column 3, The two ends of the washing machine box 1 are symmetrically equipped with cloth conduction rollers 4, and the two ends of the water washing machine box 1 are connected with a cloth conduction block 5 at the position below the cloth conduction roller 4. The inner wall of the water washing machine box 1 is connected with a washing chamber 6. A washing guide roller 7 is uniformly connected to the position above the inner wall corresponding to the washing chamber 6, an extraction chamber 8 is installed on the inner wall of the washing machine box 1 corresponding to one end of the washing chamber 6, and a drain is installed on the inner wall of ...

Embodiment 3

[0074] Embodiment 3: as Figure 1-7As shown, the present invention provides a technical solution, a knitted fabric open-width washing and shrinking device, comprising a washing machine 1, one end of the washing machine 1 is embedded with a control switch 2, and the bottom of the washing machine 1 is evenly connected with a support column 3, The two ends of the washing machine box 1 are symmetrically equipped with cloth conduction rollers 4, and the two ends of the water washing machine box 1 are connected with a cloth conduction block 5 at the position below the cloth conduction roller 4. The inner wall of the water washing machine box 1 is connected with a washing chamber 6. A washing guide roller 7 is uniformly connected to the position above the inner wall corresponding to the washing chamber 6, an extraction chamber 8 is installed on the inner wall of the washing machine box 1 corresponding to one end of the washing chamber 6, and a drain is installed on the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com