Automatic cement stirring equipment

An automatic mixing and cement technology, which is applied to cement mixing devices, clay preparation devices, unloading devices, etc., can solve the problems of low efficiency and achieve energy saving and good mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

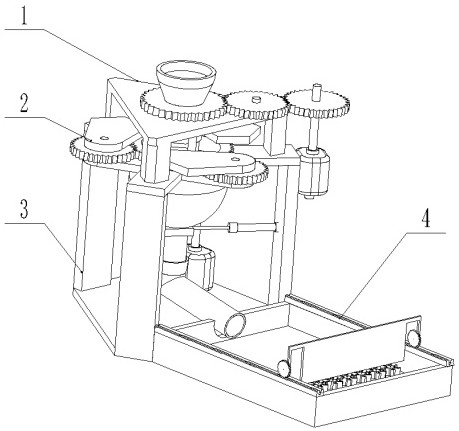

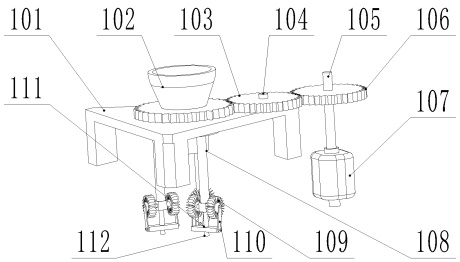

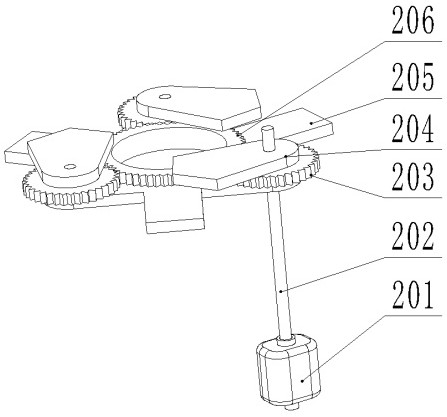

[0021] Example: figure 1 It is a schematic diagram of the overall structure of the present invention, including: a stirring module 1, a closing module 2, a cylinder module 3, and a storage module 4. It is characterized in that: the stirring module 1 includes a stirring module main body 101, and a stirring module power motor 107; the closing module 2 includes a closing module Main board 205; Cylinder module 3 comprises cylinder module support 302, mixing tank 305; Storage module 4 comprises storage module storage room 401; Stirring module main body 101 in stirring module 1 and closing module main board 205 in closing module 2 are fixedly installed, The stirring module power motor 107 is fixedly installed with the cylinder module bracket 302 in the cylinder module 3, the closed module main board 205 in the closed module 2 is fixedly installed with the mixing cylinder 305 in the cylinder module 3, and the cylinder module in the cylinder module 3 The module bracket 302 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com