System and method for monitoring make-up and running operations of well cementation and completion tools

A technology for cementing and completing wells and tools, which is used in earth-moving drilling, wellbore/well components, etc., can solve problems such as affecting construction quality, inaccurate make-up torque, and inaccurate make-up, so as to improve on-site work efficiency and avoid problems. Human error, easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

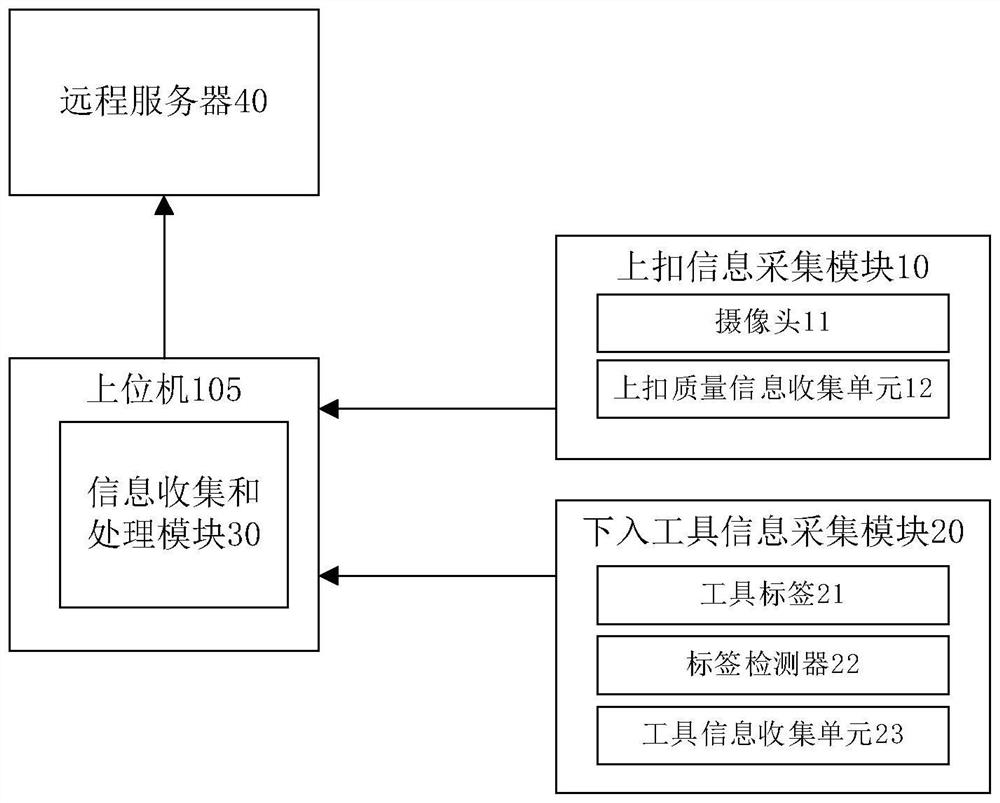

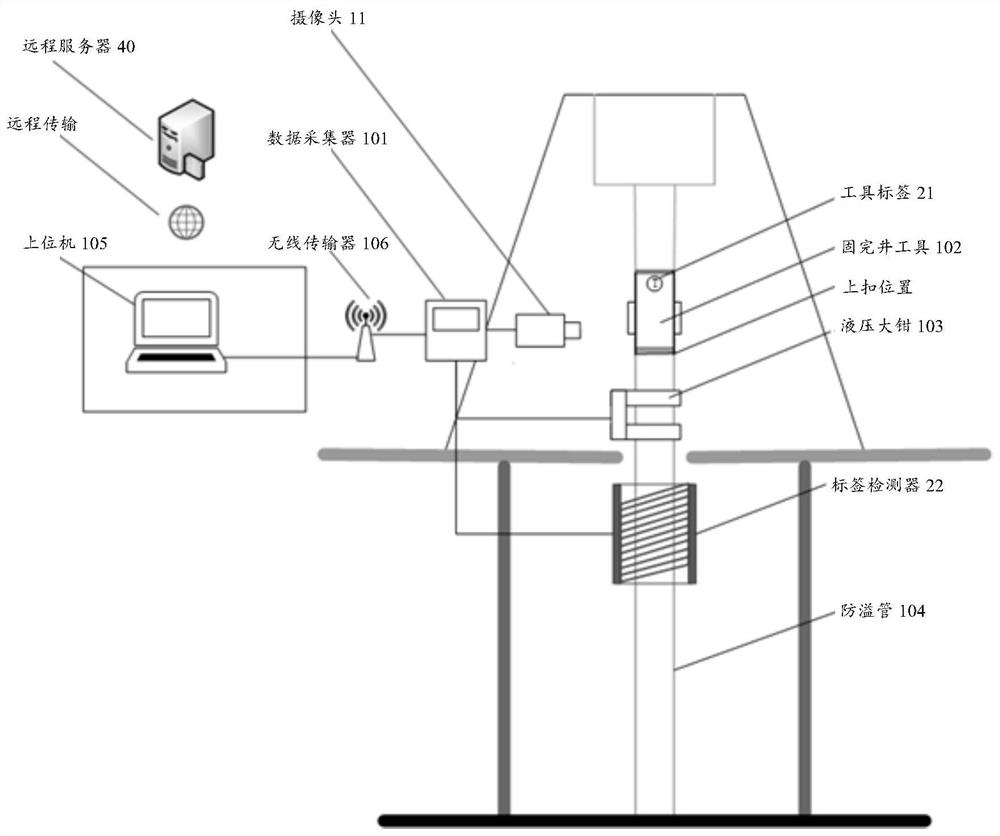

[0028] figure 1 It is a schematic diagram of the overall structure of a system for monitoring make-up and running-in operations of cementing and completion tools according to an embodiment of the present invention. figure 2 It is a schematic diagram of the application environment of the system for monitoring the make-up and running-in operations of cementing and completion tools according to the embodiment of the present application. Combine below figure 1 and figure 2 The structure, application environment and other aspects of the system of the present invention are described. Such as figure 1 and figure 2 As shown, the system includes: a buckle-up information collection module 10 , a running tool information collection module 20 and an information collection and processing module 30 . Wherein, the make-up information collection module 10 is arranged at the wellhead, and is used for collecting make-up quality information when the current cementing and completion tool ...

Embodiment 2

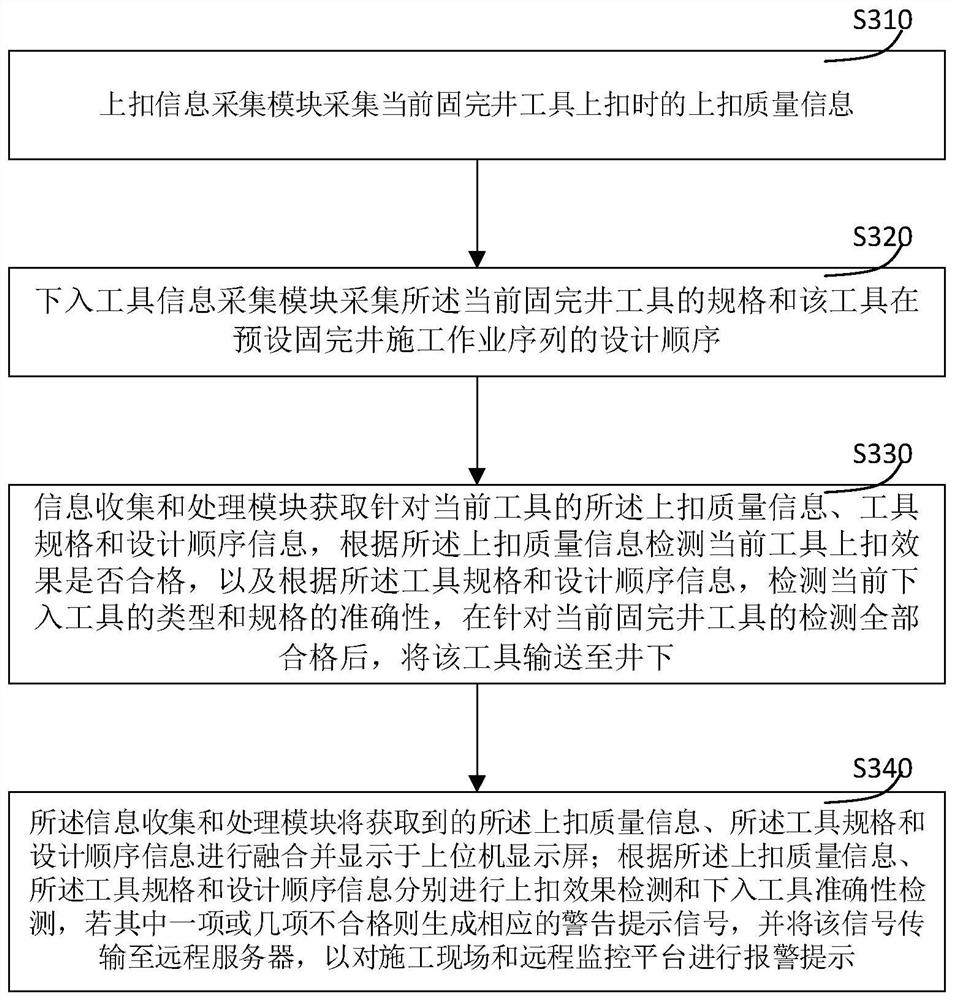

[0043] Based on the system of Embodiment 1 of the present invention, the present invention also proposes a method for monitoring the make-up and run-in operation of cementing and completion tools. Incoming operations are monitored in real time. image 3 A step diagram of a method for monitoring make-up and running-in operations of a cementing and completion tool according to an embodiment of the present application. Refer below image 3 The above method will be described.

[0044] Such as image 3 As shown, in step S310, the make-up information collection module 10 collects the make-up quality information of the current cementing and completion tool when making up. Step S320: The running tool information collection module 20 collects information including the specification of the cementing and completion tool currently to be run in, and the design sequence of the tool in the preset cementing and completion operation sequence. Step S330: The information collection and proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com