Pump body of vertical pipeline pump capable of reducing hydraulic losses

A technology of vertical pipelines and pipelines, applied in non-variable pumps, components of pumping devices for elastic fluids, pumps, etc., can solve uneven distribution of liquid flow velocity, cavitation and efficiency effects, and pressure distribution Inequalities, to achieve the uniform velocity distribution of the liquid flow field, improve the anti-cavitation performance, and the effect of no impact on the velocity distribution of the liquid flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

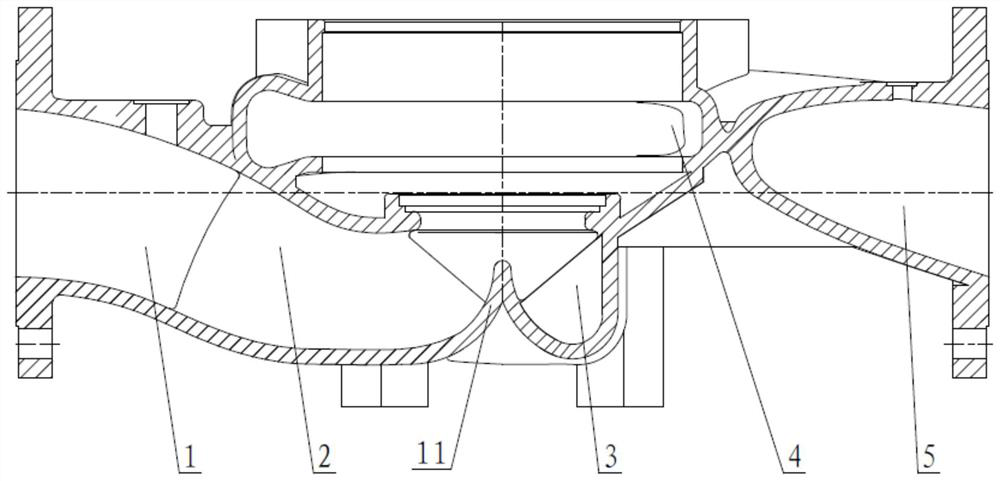

[0020] Such as figure 1 As shown, a vertical pipeline pump body of the present invention that reduces hydraulic loss includes a water absorption chamber cavity 4, a water inlet pipe 1 communicating with the axially lower end of the water absorption chamber cavity 4, and the water absorption chamber cavity 4. The water outlet pipe 5 connected to the side wall of the chamber cavity 4; the connection line between the inlet center of the water inlet pipe 1 and the outlet center of the water outlet pipe 5 is perpendicular to the axis of the water absorption chamber cavity 4;

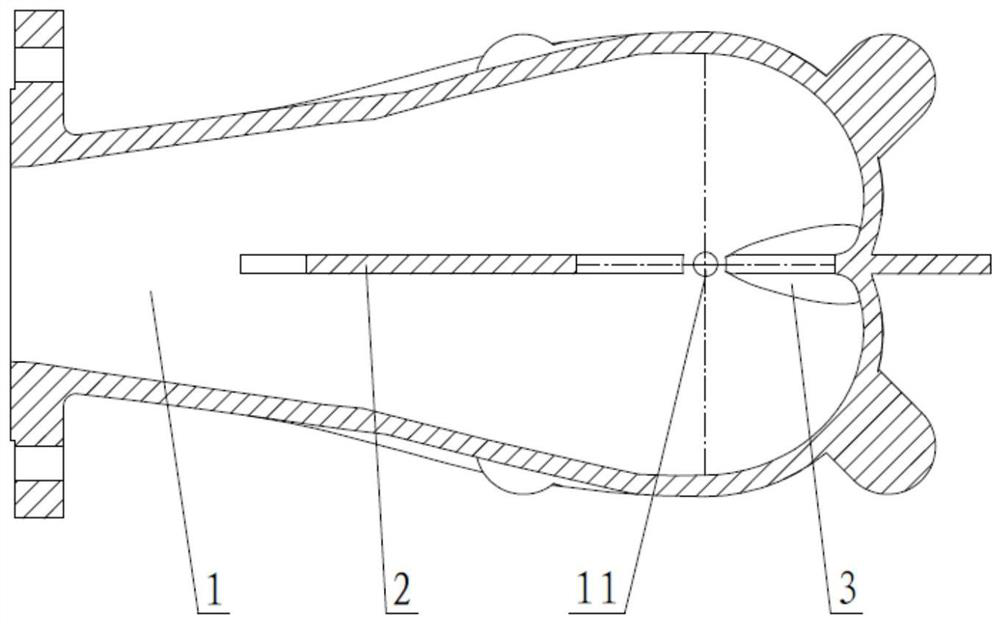

[0021] Such as figure 2 As shown, the inner wall of the inner cavity of the water inlet pipe 1 opposite to the water inlet of the water absorption chamber body 4 has a diversion cone 11 structure extending inward;

[0022] The middle part of the inner cavity of the water inlet pipe 1 is provided with an inlet partition 2 that extends along the pipe and divides the pipe into two channels equally, and the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com