Inorganic ion exchange resin mixing tank

An inorganic ion exchange and mixing tank technology, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of easy stratification and low artificial mixing efficiency, and achieve the effects of promoting flow strength, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

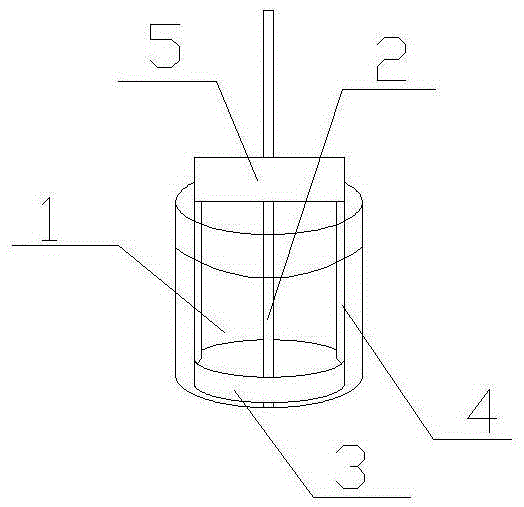

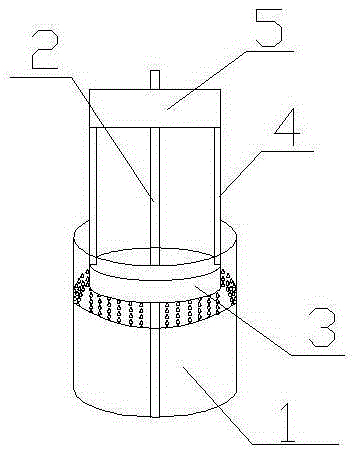

[0014] refer to figure 1 , figure 2 and image 3 An inorganic ion exchange resin mixing tank shown includes a tank body 1 and a column 2 arranged inside the tank body 1, and the column 2 extends outside the tank body 1

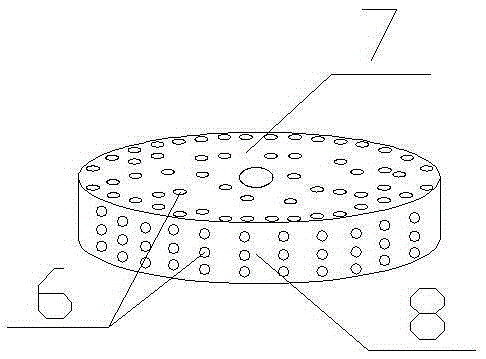

[0015] The column 2 is provided with a disc 3 passing through it, the height of the disc 3 is set to 5-8 cm, and the bottom 7 and the periphery 8 of the disc 3 are provided with a number of small holes 6, The left side and the right side of the disc 3 are fixed with a vertical guide rod 4, the guide rod 4 is parallel to the column 2, and extends to the outside of the tank body 1, and the guide rod 4 is connected with an oil cylinder 5 .

[0016] The tank body 1 is configured as a circle whose diameter is larger than that of the disk 3 .

[0017] The tank body 1, disc 3, column 2, guide rod 4 and other parts in contact with materials are made of stainless steel.

[0018] The oil cylinder 5 is arranged on the column 2, and the center of the oil cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com