Fluid mixer based on shape memory polymer

A memory polymer and fluid mixing technology, applied in the direction of mixers, mixing methods, chemical instruments and methods, etc., to achieve the effect of adjustable shape and size, low cost, and maintaining mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

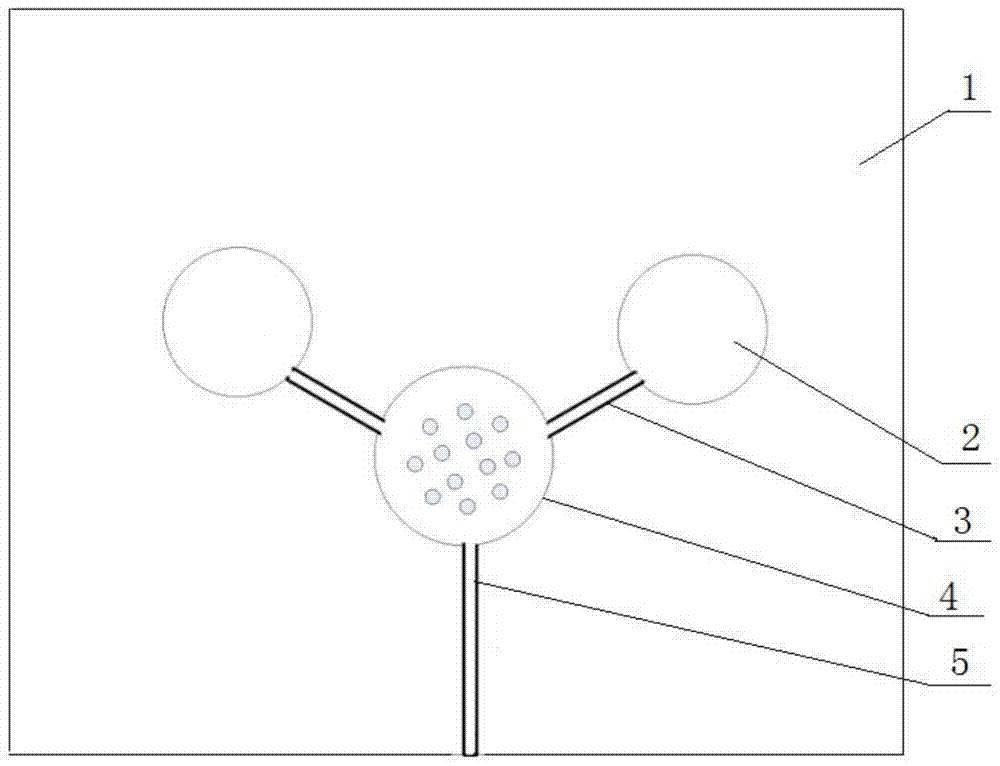

[0033] figure 1 Shown is a fluid mixer for simultaneous mixing of two solutions. The material of the base 1 is polyurethane shape memory polymer, the glass transition temperature of which is about 35°C, the size of the base 1 is 60mm×60mm×4mm, and a heating plate is attached under the base 1. like figure 1 As shown, the surface of the substrate 1 has two liquid storage areas 2 and a liquid mixing area 4, and the two liquid storage areas 2 and one liquid mixing area 4 are cylindrical concaves obtained after indentation pre-deformation of the initial plane of the substrate 1. In the pre-deformation area of the groove, the temperatures of the shape recovery of the liquid storage area 2 and the liquid mixing area 4 are different, which are 35°C and 45°C respectively. The radius of the groove in the liquid storage area 2 is 5 mm, and the depth is 2 mm. The radius of the groove in the liquid mixing area 4 is 7 mm, and the depth is 3 mm. A small cylindrical indentation pre-defor...

Embodiment 2

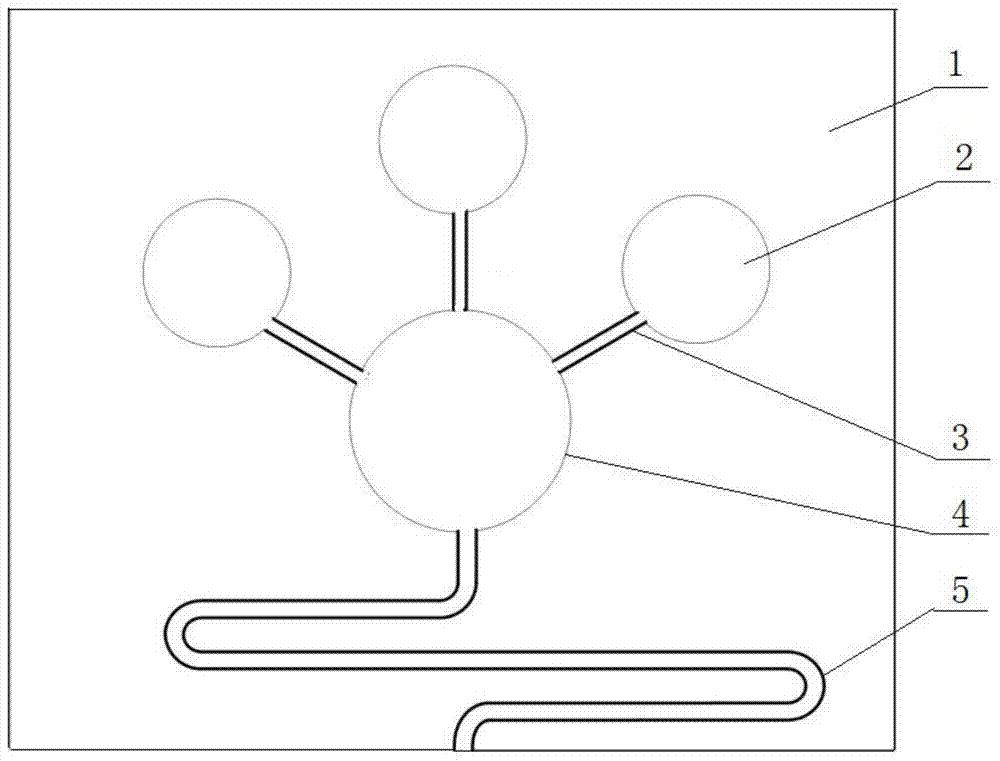

[0036] figure 2 A fluid mixer for the gradual mixing of three solutions. The material of the matrix 1 is epoxy polymer, and its glass transition temperature is about 45°C. The size of the substrate 1 is 40mm×40mm×4mm, and a heating plate is attached under the substrate 1 . like figure 2As shown, the surface of the substrate 1 has three liquid storage regions 2 and one liquid mixing region 4 . The three liquid storage areas 2 and one liquid mixing area 4 are all pre-deformed areas of cylindrical grooves obtained by indentation pre-deformation on the initial plane of the substrate 1 . The shape recovery temperature of two of the three liquid storage areas 2 is 45°C, the shape recovery temperature of one liquid storage area 2 is 55°C, and the shape recovery temperature of one liquid mixing area 4 is 65°C. The grooves of the three liquid storage areas 2 have a sectional radius of 3 mm and a depth of 1.5 mm; the groove of one liquid mixing area 4 has a sectional radius of 8 m...

Embodiment 3

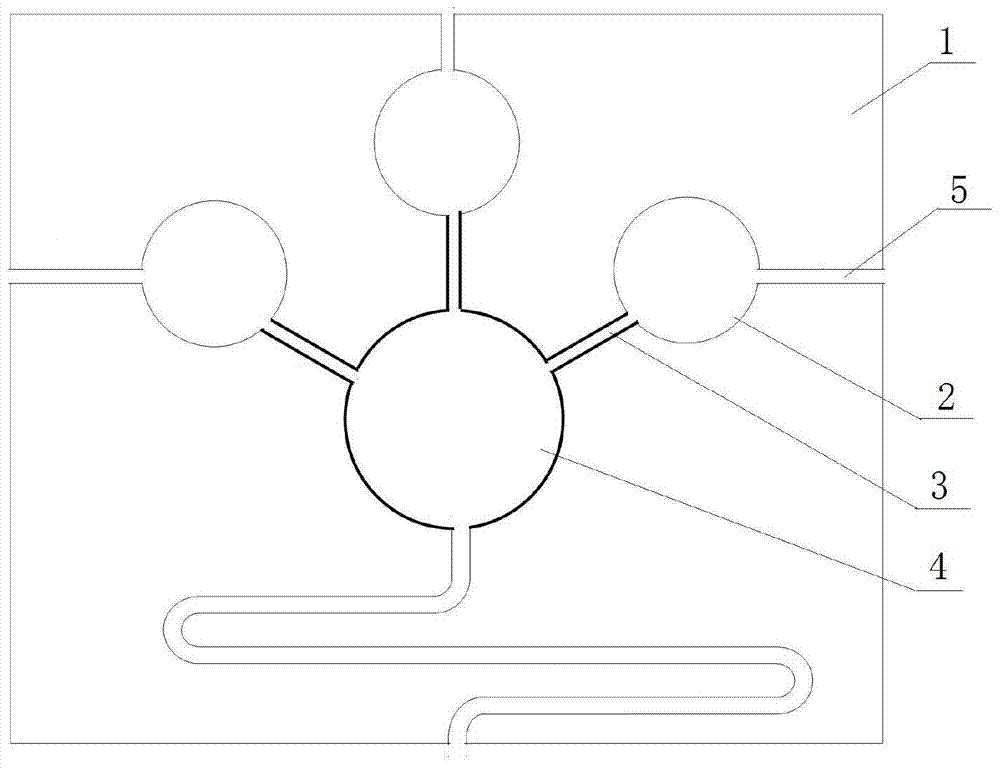

[0040] The difference from Embodiment 2 is that the liquid mixing zone 4 is a plane formed by pre-deformation of the initial groove shape on the surface of the substrate, and the shape recovery temperature is 45° C.; a second connecting the liquid mixing zone 4 and the edge of the substrate 1 The channel area 5 is a flat surface obtained by pre-deformation of the original strip-shaped groove shape, and the shape recovery temperature is 65°C. In use, the difference from Example 2 is that when heated to 45°C, the shape recovery temperature is 45°C. The shape of the grooves in the two storage areas 2 gradually recovers to a plane, and at the same time, the mixed liquid area 4 gradually recovers from the plane to the original. The shape of the groove, the two liquids flow into the mixed liquid area 4, when heated to 55 ° C, the shape recovery temperature is 55 ° C in the groove of the liquid storage area 2, the shape recovery occurs and becomes a plane, and the solution in it gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com