Fuel cell separator and single fuel cell

A fuel cell and single cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., to achieve the effect of reducing the reduction of power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present disclosure will be described in detail. In addition, this indication is not limited to the following embodiment, Various deformation|transformation can be implemented within the range of the main point which was disclosed.

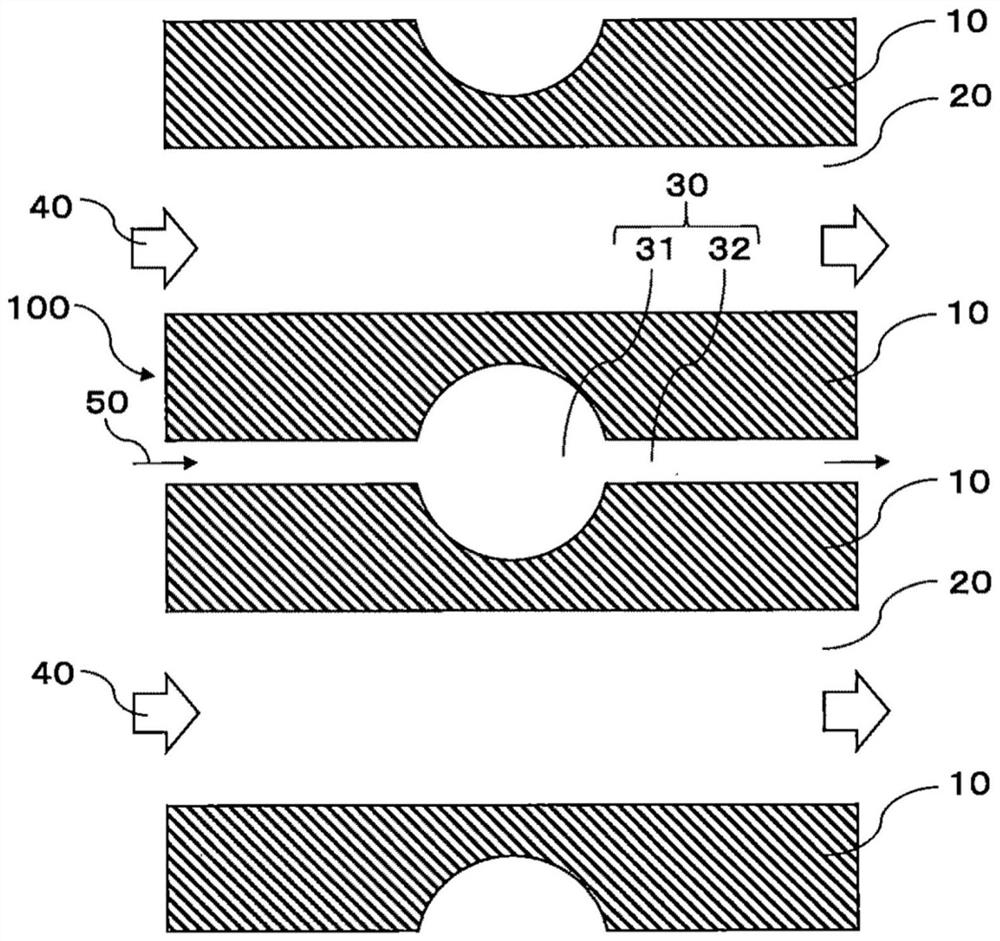

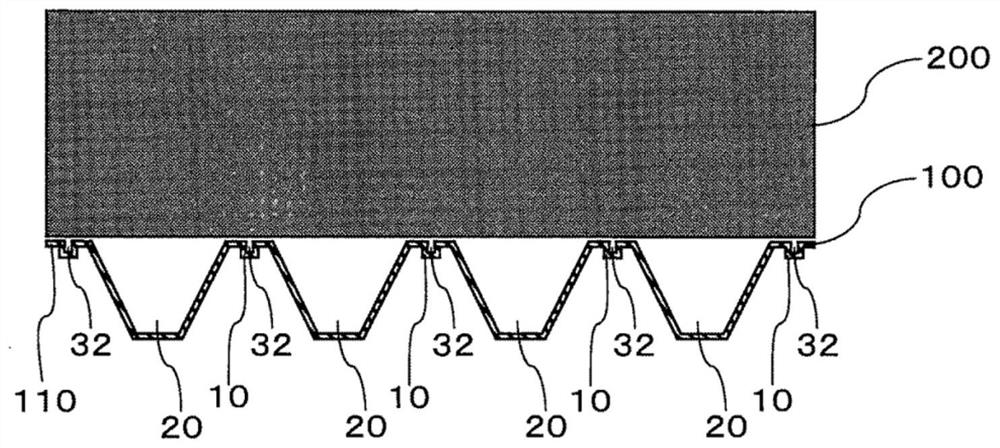

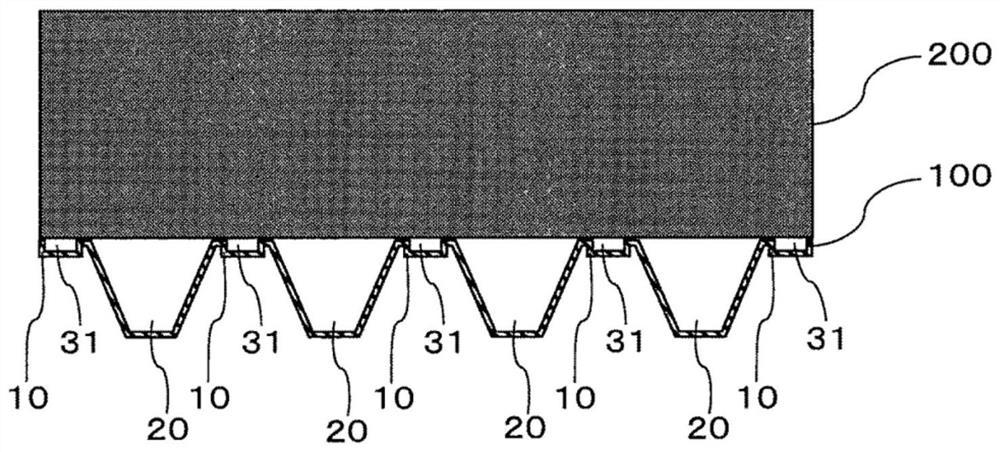

[0026] Separator for fuel cells

[0027] The fuel cell separator of the present disclosure has a plurality of gas flow paths separated from each other by ribs, on the surface of the gas flow path, on the surface of the ribs, there are liquid water flow paths separated from the gas flow path along the gas flow path, In addition, the liquid water flow path has an expansion area, and the cross-sectional area of the expansion area of the liquid water flow path in the direction perpendicular to the flow direction is larger than the cross-sectional area of other regions of the liquid water flow path in the direction perpendicular to the flow direction.

[0028] The fuel cell separator of the present disclosur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com