Vegetable core cooking device

A cooking device and vegetable core technology, which is applied to cooking utensils, household utensils, applications, etc., can solve the problems of no crispy and sweet taste, unsuitable for vegetable cores, messy vegetables, etc., and achieves crispy and sweet taste and uniform cooked degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

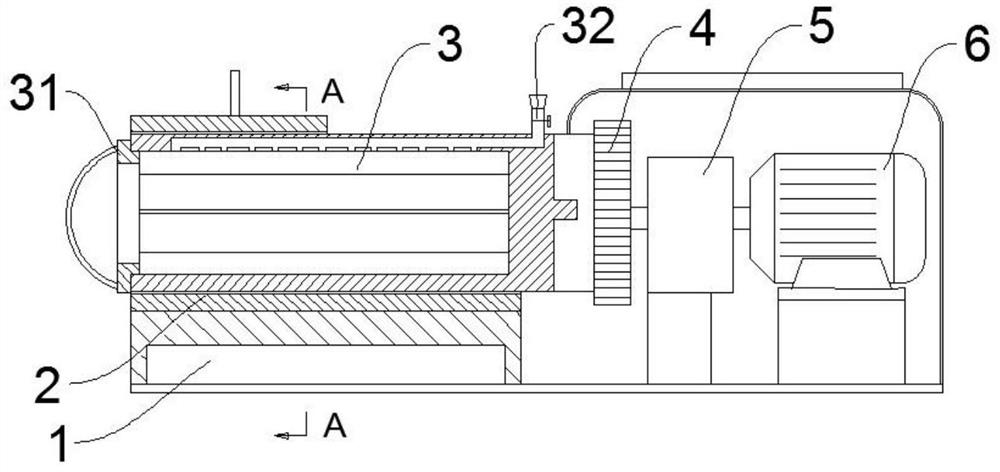

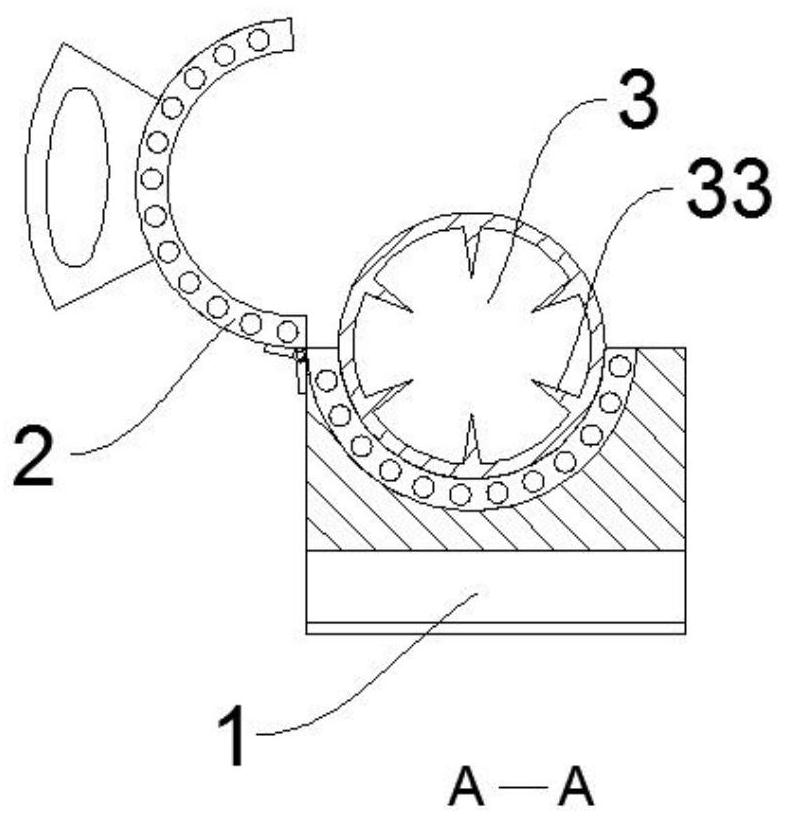

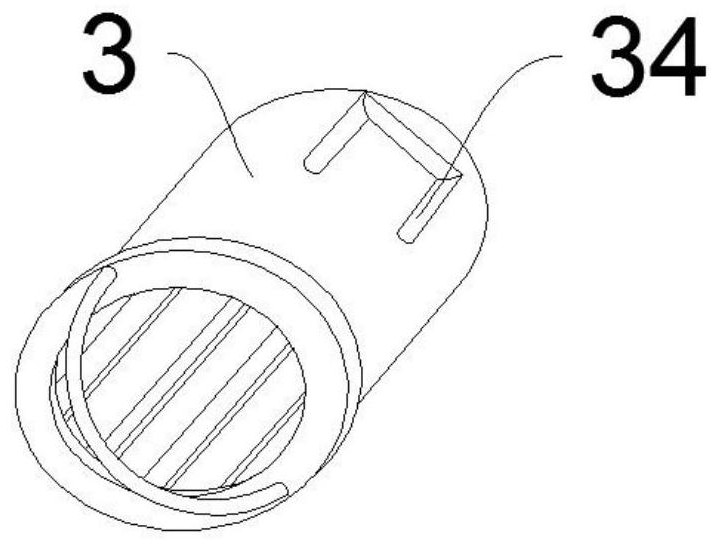

[0018] Such as figure 1 , figure 2 and image 3 As shown, a cabbage cooking device includes a support 1, a heat generator 2, a rotating pot 3, a gear 4, a reducer 5 and a micro motor 6, and the heat generator 2 is installed on the support 1 to produce heat The device 2 is composed of a lower arc block and an upper arc block. The lower arc block and the upper arc block are connected by hinges to form a cylindrical shape. Both the lower arc block and the upper arc block are provided with electric heating wires. The length of the upper arc block is half of the block, and the end of the upper arc block is flush with the end of the lower arc block after installation. Make the heat generated by the upper arc block only reach the middle of the cabbage core, combined with the heat generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com