Process method for accurately controlling gluing amount of U-shaped groove lining of stator wire bar

A stator bar and precise control technology, which is applied to the surface coating device, coating, manufacturing of motor generators, etc. problem, to achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

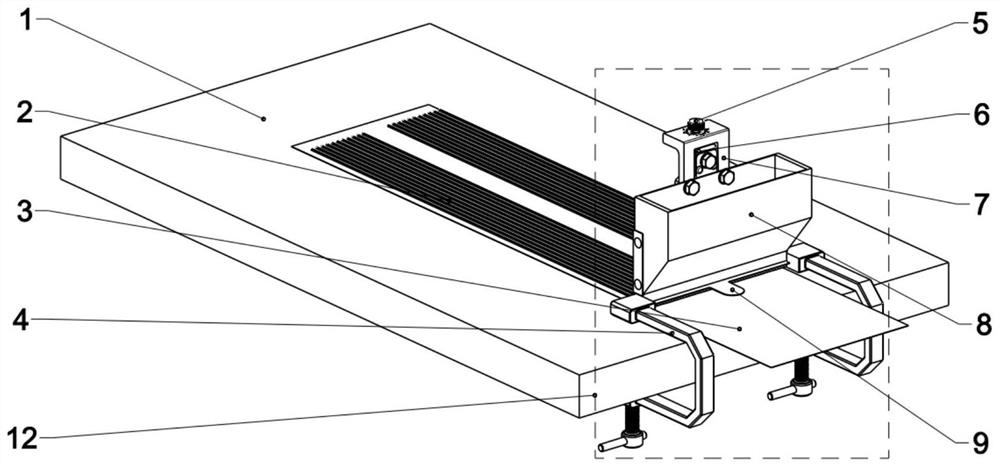

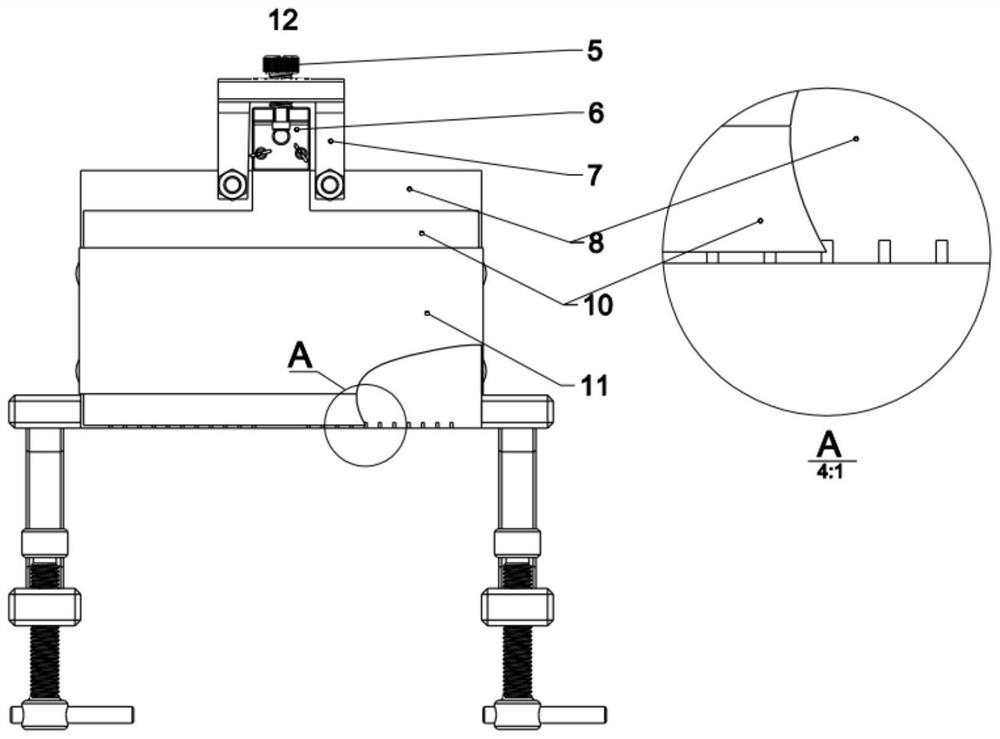

[0025] Such as figure 1 , figure 2 As shown, the present invention provides a process method for accurately controlling the amount of glue applied to the U-shaped groove lining of the stator wire rod, aiming at precisely controlling the thickness of the glue applied to the U-shaped groove lining before the stator wire rod of the hydroelectric generator set is installed, and improving the thickness of the stator wire rod. While improving the installation quality, it saves the installation cycle and material costs. Technical scheme of the present invention is:

[0026] 1) Use the glue amount control tool 12 to brush the semiconductor glue on the semiconductor tank backing paper 3, and the semiconductor glue is formed from the height-adjustable sawtooth formed by the glue storage hopper 8 of the glue amount control tool 12 and the glue thickness adjustment baffle plate 10 The evenly distributed rectangular glue outlets flow out, and the semiconducting glue 2 after brushing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com