Weight classification device for large logistics boxes

A sorting device and logistics box technology, applied in the field of large-scale logistics box weight sorting device, can solve the problems of large manpower and material resources, unintuitive weight reflection, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

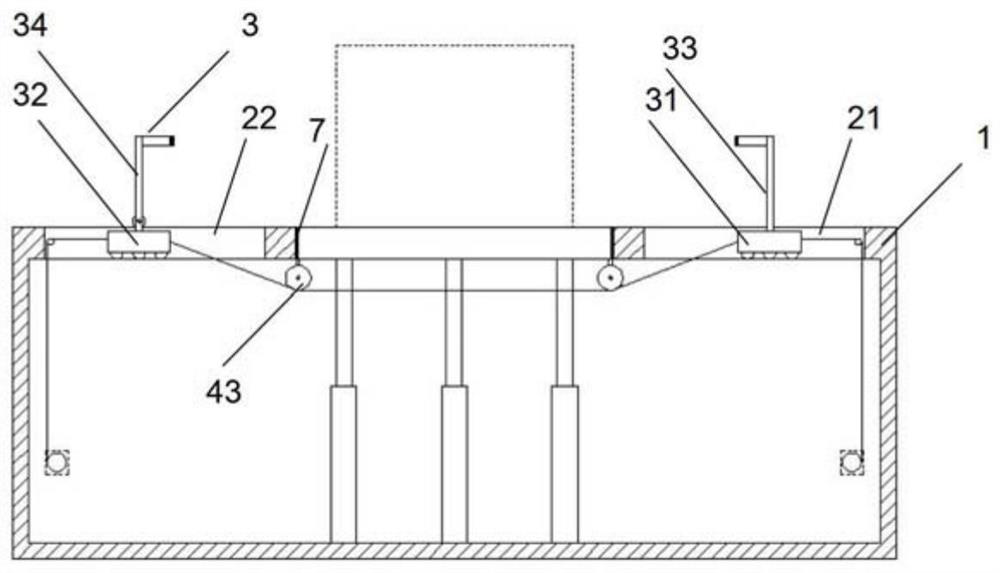

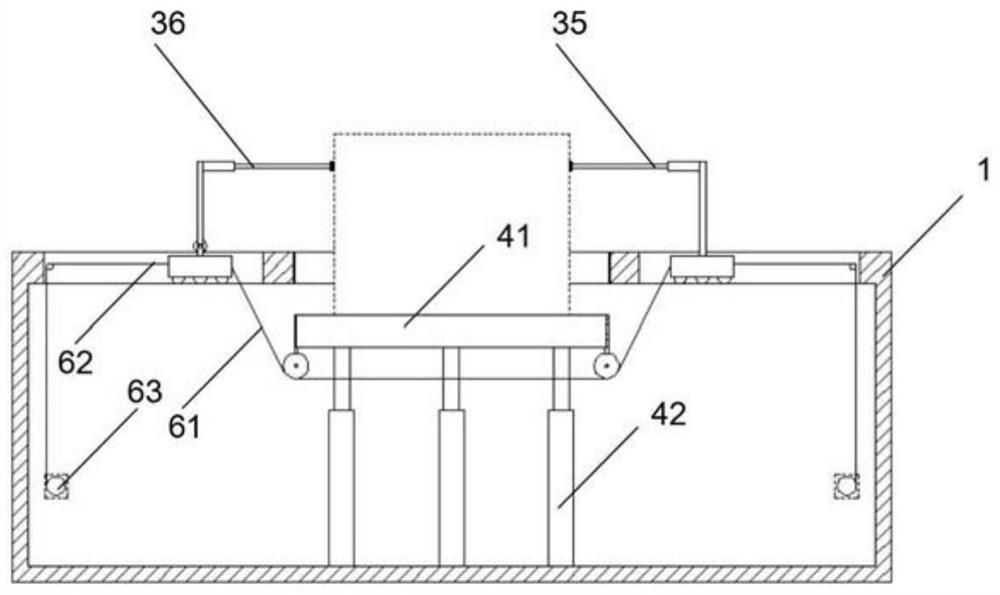

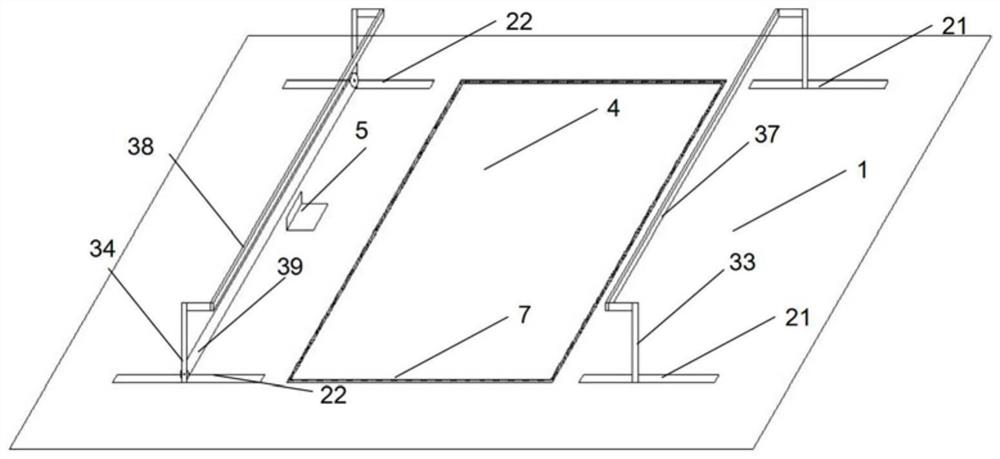

[0025] Attached below figure 1 to attach Figure 5 The present invention is further described in detail so that those skilled in the art can implement it with reference to the description.

[0026] Such as Figure 1-3 As shown, the classification device of the present invention performs weight classification for large logistics boxes with the same size, including a housing 1, a first parallel slide rail group 21 and a second parallel slide rail group 22 located on the upper surface of the housing 1, which can be moved along the slide rails. The sliding marking part 3, the lifting part 4 located in the middle of the upper surface of the housing 1 and surrounded by the first parallel slide rail group 21 and the second parallel slide rail group 22, is located on the side of the marking part 3 and is located in the first parallel slide rail The image acquisition part 5 between the groups 21, each slide rail group has two front and rear slide rails, the traction part 6 located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com