Machining center lead screw protective cover

A machining center and protective cover technology, which is applied in the field of machining center screw protective cover, can solve the problems of metal debris flying up, screw damage, etc., and achieve the effect of preventing flying into the screw rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

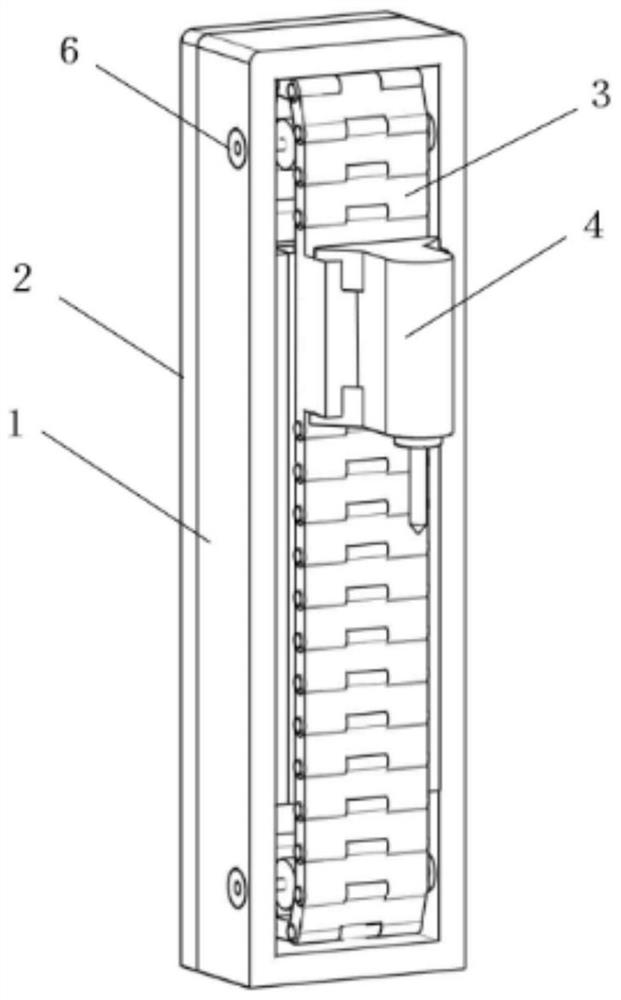

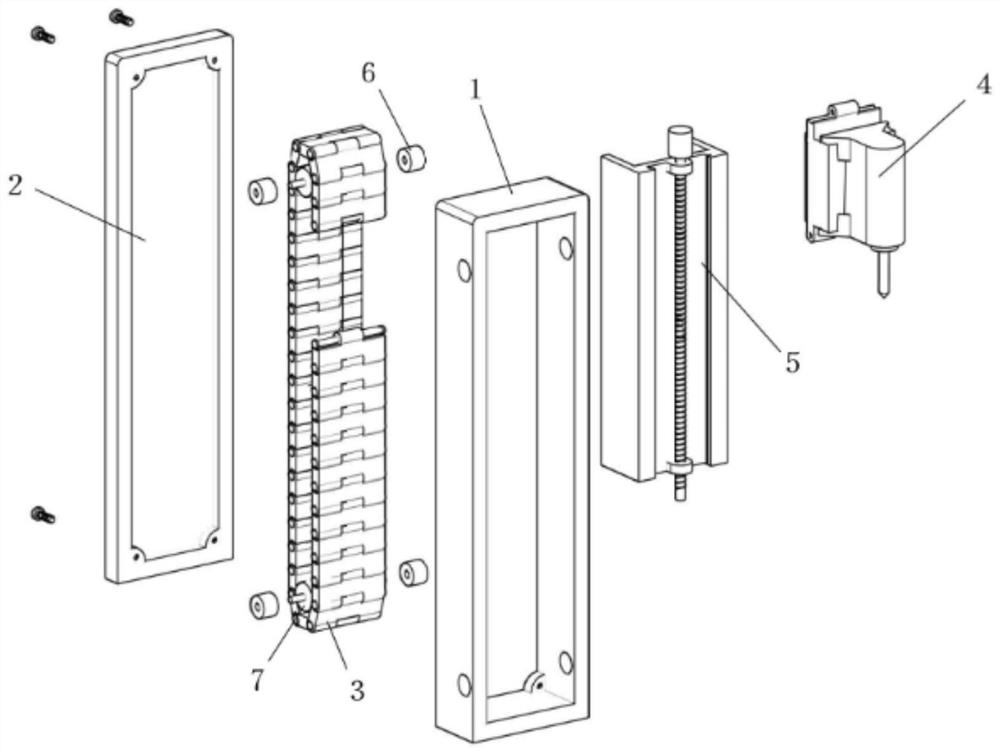

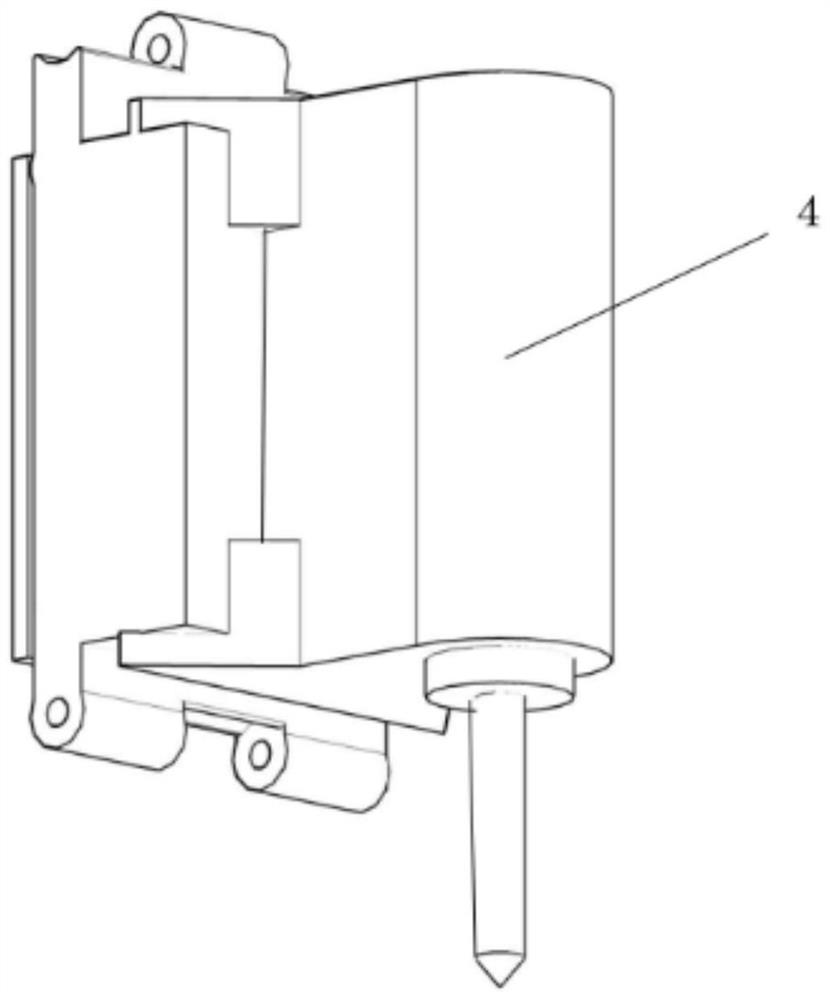

[0016] The screw protective cover of the machining center includes a screw slide rail 5, a processing head 4, and the processing head 4 slides on the screw slide rail 5, and also includes a protection chain plate 3; the protection chain plate 3 consists of several The chain blocks are hinged to each other, the front and rear ends of the base of the processing head 4 are provided with chain links that can be hinged with the chain blocks of the protection chain plate 3; the chain blocks of the protection chain plate 3 are connected to the processing head. 4. The chain links at the front and rear ends of the base are hinged together to form a closed annular chain block ring; the screw slide rail 5 is located inside the chain block ring.

[0017] The screw protective cover of the machining center also includes a fixed frame 1 and a chain shaft 7; the screw slide rail 5, the processing head 4 and the protective chain plate 3 are embedded in the fixed frame 1, and there are two chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com