An optimal allocation method of high-speed train braking force considering adhesion and comfort

A technology for high-speed trains and optimized distribution, applied in the direction of brakes, etc., can solve problems such as the sticking limit of each carriage of the weight, the lack of in-depth research on the passenger riding comfort distribution algorithm, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in combination with specific embodiments.

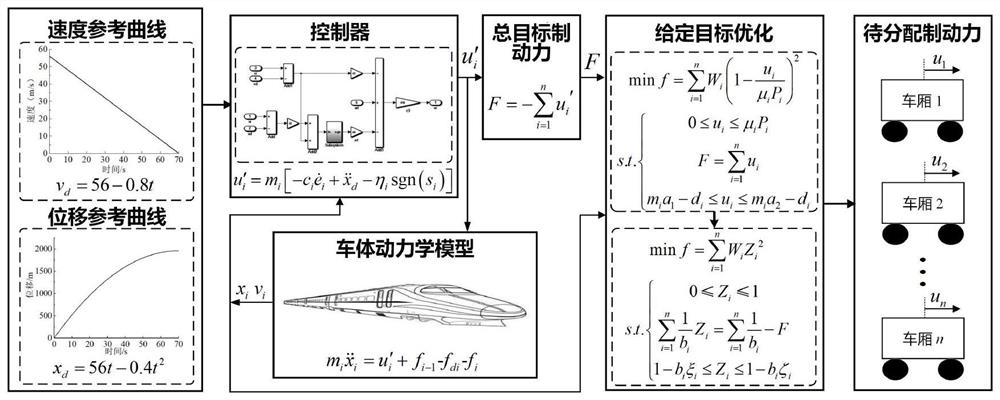

[0061] A high-speed train braking force optimization distribution method considering adhesion and comfort; comprising the following steps:

[0062] S1. By performing dynamic analysis on all compartments of the high-speed train, the dynamic model of the high-speed train is obtained, and a dynamic equation for the multi-particle model of the high-speed train is established;

[0063] The train dynamics model is:

[0064]

[0065] Among them, i=1,2,..., n is the number of compartments; m i is the mass of the i-th carriage; is the acceleration of the i-th carriage; u′ i is the control input of the i-th car; f di Indicates the running resistance acting on the i-th carriage; f i Indicates the interaction force between the i-th car and the i+1-th car;

[0066] The formula for calculating the basic resistance of a high-speed train is:

[0067]

[0068] in, is a const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com