Pressing device for pressing long-strip-shaped plastic label to side face of furniture plate

A pressing device and strip-shaped technology, which is applied in the field of pressing devices, can solve the problems of poor assembly effect, uncontrollable manual assembly pressing position and strength, and affecting the appearance, so as to achieve the effect of uniform and controllable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

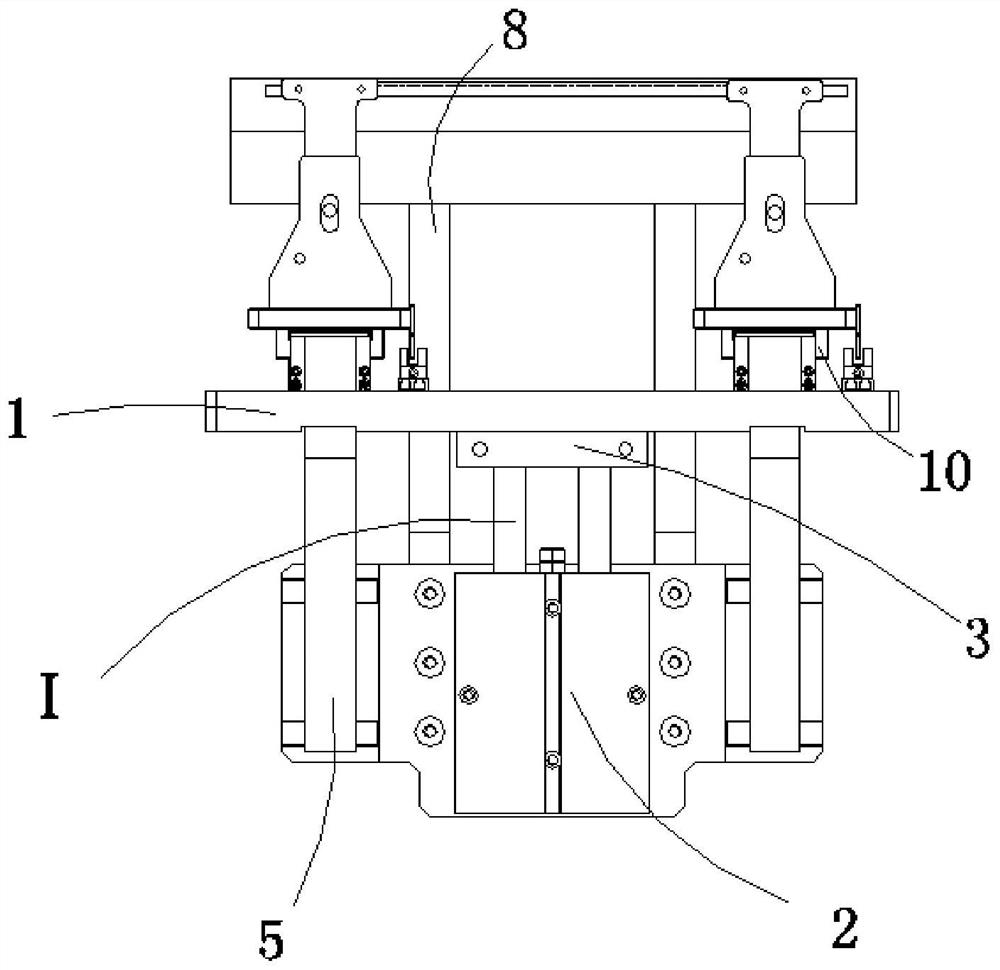

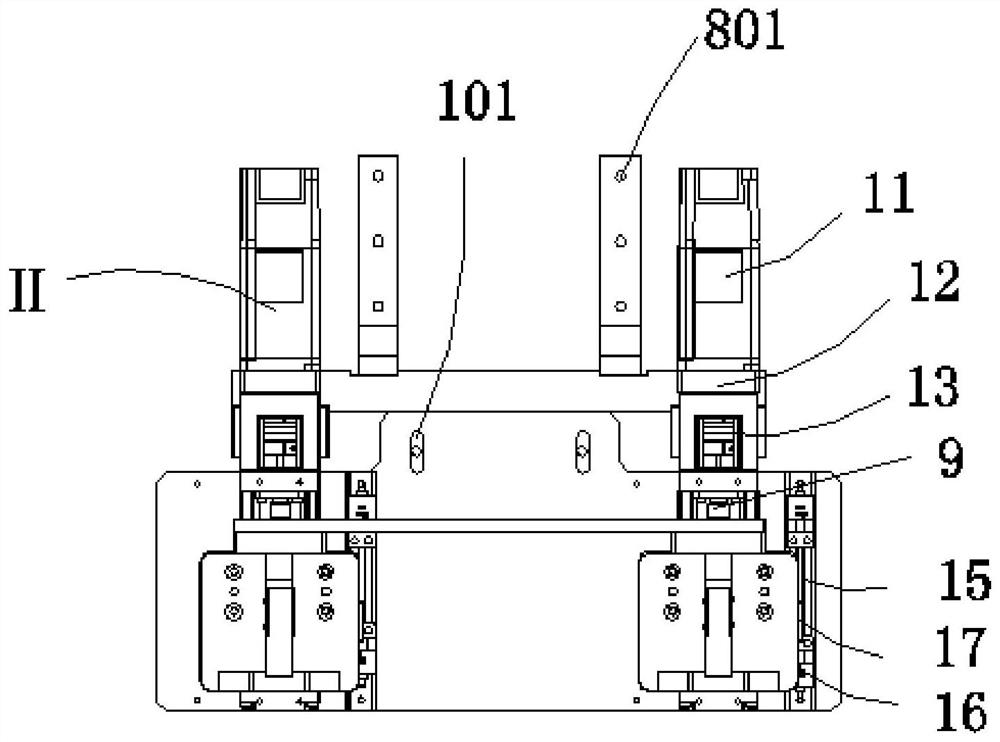

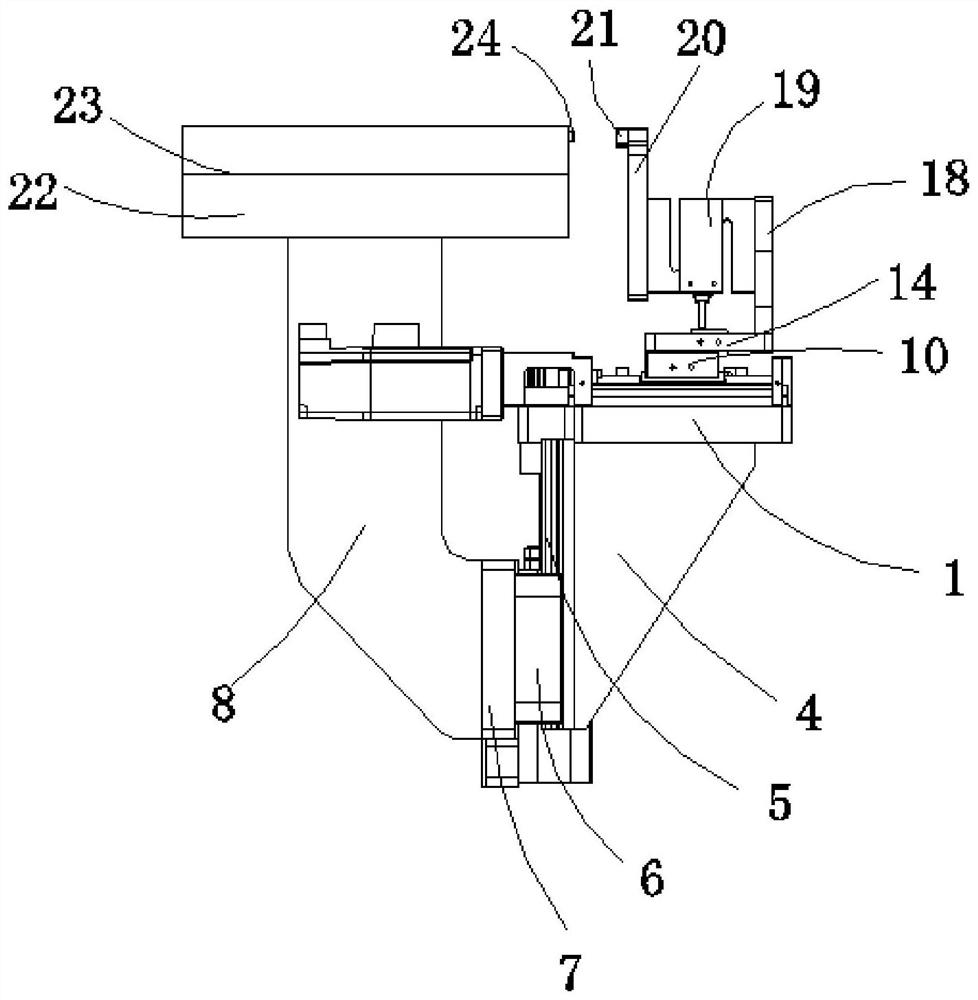

[0021] Examples, see attached Figure 1~3 , a pressing device for pressing a strip-shaped plastic label to the side of a furniture board, including a horizontal base plate 1 and a lifting mechanism I installed below the horizontal base plate and capable of lifting the horizontal base plate. In this embodiment, the horizontal base plate It is a flat plate structure, and the horizontal bottom plate is a convex structure.

[0022] The lifting mechanism includes a lifting cylinder 2 below the horizontal base plate, a lifting plate 3 installed on the piston rod of the lifting cylinder and a lifting slide assembly that can make the horizontal base plate rise and fall smoothly, and the lifting plate is fixedly installed on the bottom of the horizontal base plate. The flange position of the protruding structure of the horizontal base plate is provided with a slotted hole 101, and the lifting plate can be installed directly below the flange position of the horizontal base plate through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com