Press for assembly of vertical multistage submersible pump impeller

A technology for submersible pumps and presses, applied in the field of installation, can solve the problems that are not conducive to ensuring the quality of impeller installation, time-consuming and labor-intensive, etc., and achieve the effects of simple structure, convenient use, and economical and practicality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

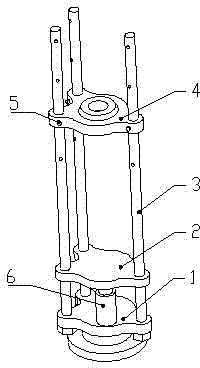

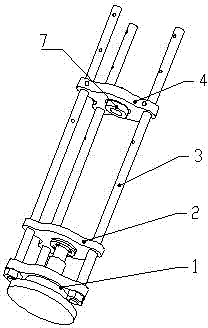

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

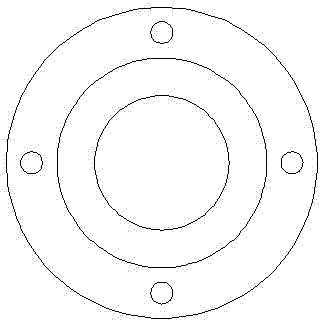

[0013] The vertical multistage submersible pump impeller assembly press of the present invention is mainly composed of an isosceles triangle base 1, a lifting platform 2, a column 3, a positioning platform 4, a hydraulic cylinder 6 and an impeller fixing seat 7; The base 1 is fixed on the chassis, three uprights 3 are respectively fixed on the three corners of the base 1, and the three uprights 3 are successively set with a lifting platform 2 and a positioning platform 4 with the same structure as the base 1, and the upper parts of the three uprights 3 are arranged at intervals. A plurality of positioning holes, the middle part of the positioning platform 4 has an impeller shaft hole, and the impeller shaft hole on the opposite side of the positioning platform 4 and the lifting platform 2 is provided with an impeller fixing seat 7, and the impeller fixing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com