Movable chute based on trestle and trestle

A mobile, trestle technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of time-consuming and labor-intensive, high manufacturing cost, affecting construction efficiency, etc., and achieve the effect of convenient use, shortening the overall length, and reducing moving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will be further described in detail below in conjunction with the drawings and specific embodiments of the specification.

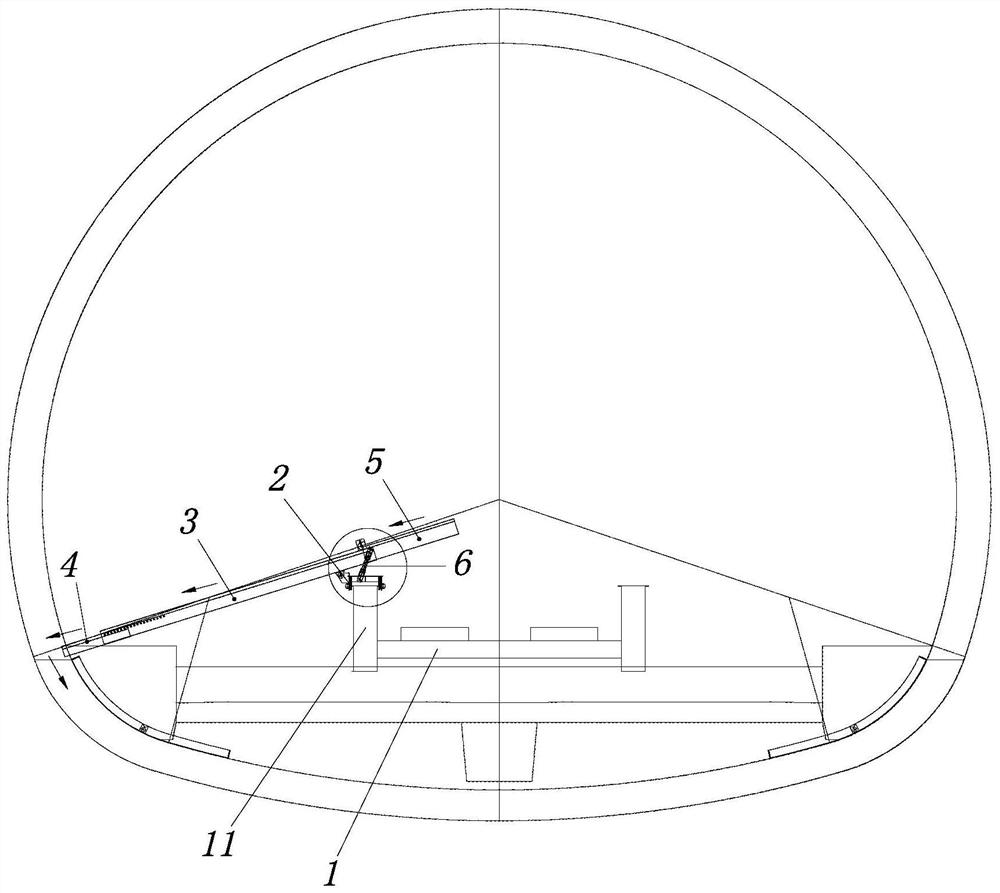

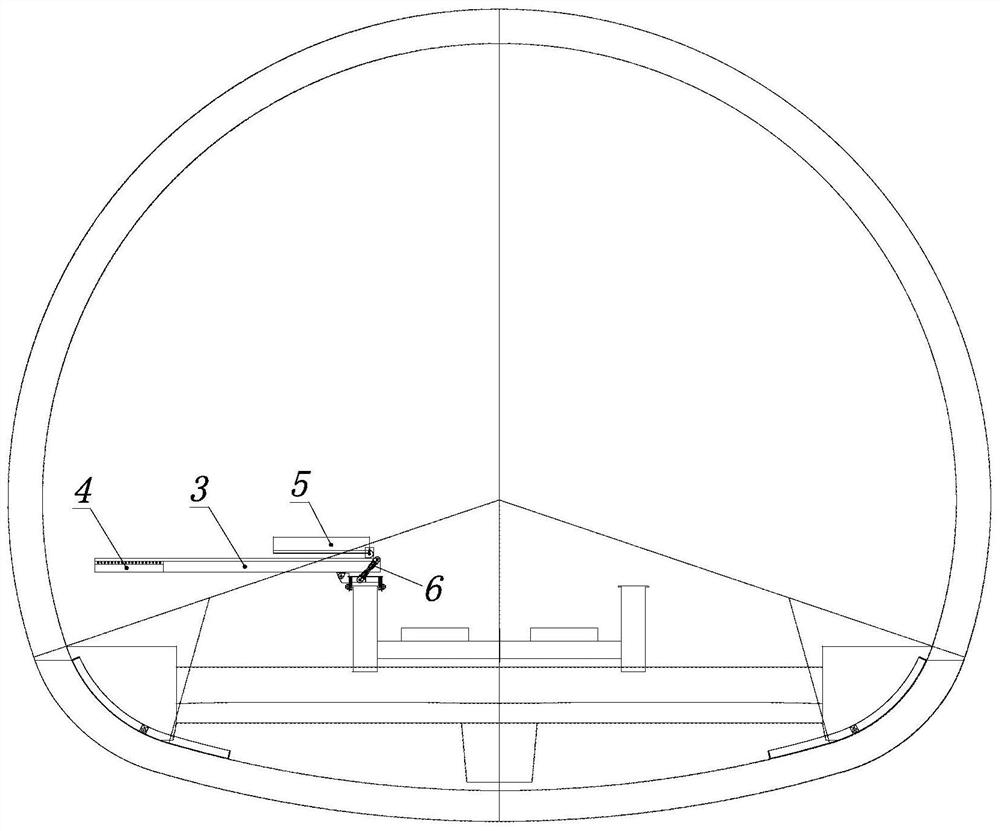

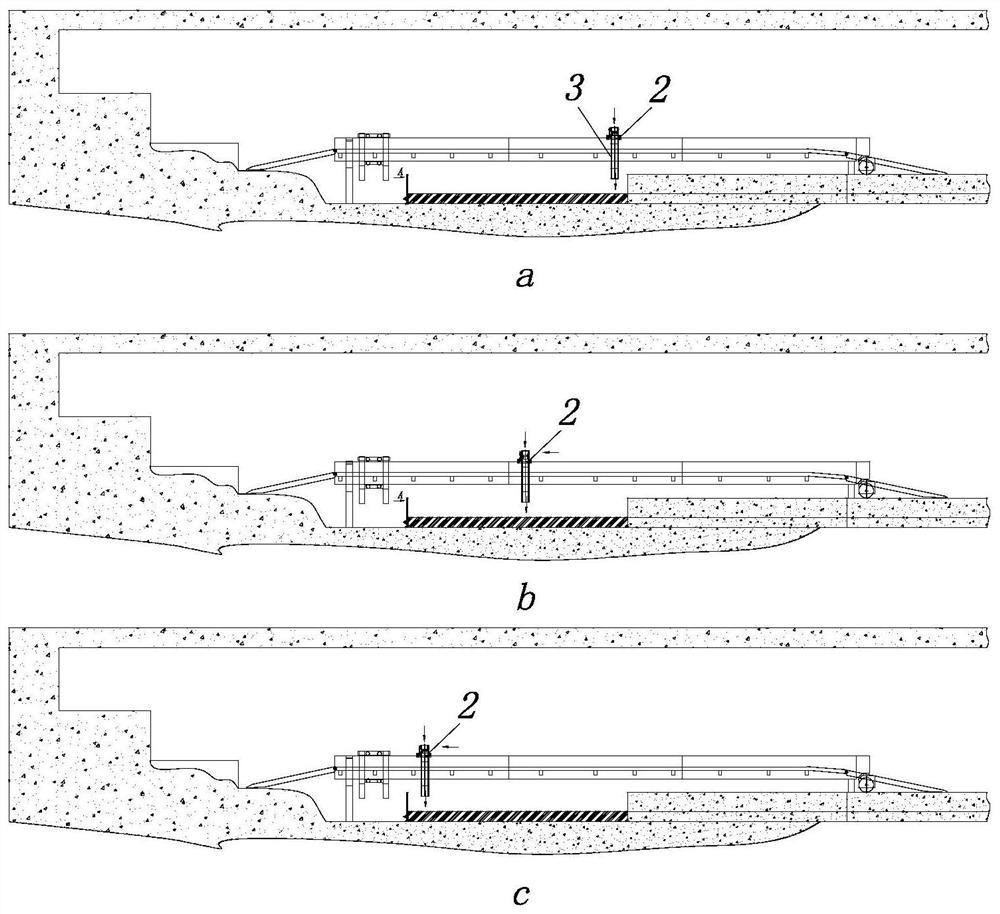

[0021]Figure 1 to Figure 4An embodiment of the movable chute based on the trestle bridge of the present invention is shown. The movable chute based on the trestle bridge of this embodiment includes a base 2 that can move along the length of the trestle 1, and a main hinged on the base 2 The chute 3 and the base 2 are arranged on the side of the trestle 1, the lower end of the main chute 3 is connected with at least one sliding chute 4, and the upper end of the main chute 3 is connected with a rotating chute 5.

[0022]The movable chute based on the trestle bridge has its own base 2 that can move along the length of the trestle bridge 1. The base 2 can drive the main chute 3, sliding chute 4 and rotating chute 5 to move along the side of the trestle bridge 1, which is convenient for changing the construction location without With the aid of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com