A machine-made sand automatic loading system

A kind of machine-made sand and automatic technology, applied in the direction of conveyor, loading/unloading, conveyor objects, etc., to achieve the effect of reasonable structure design, reduce operation process and meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

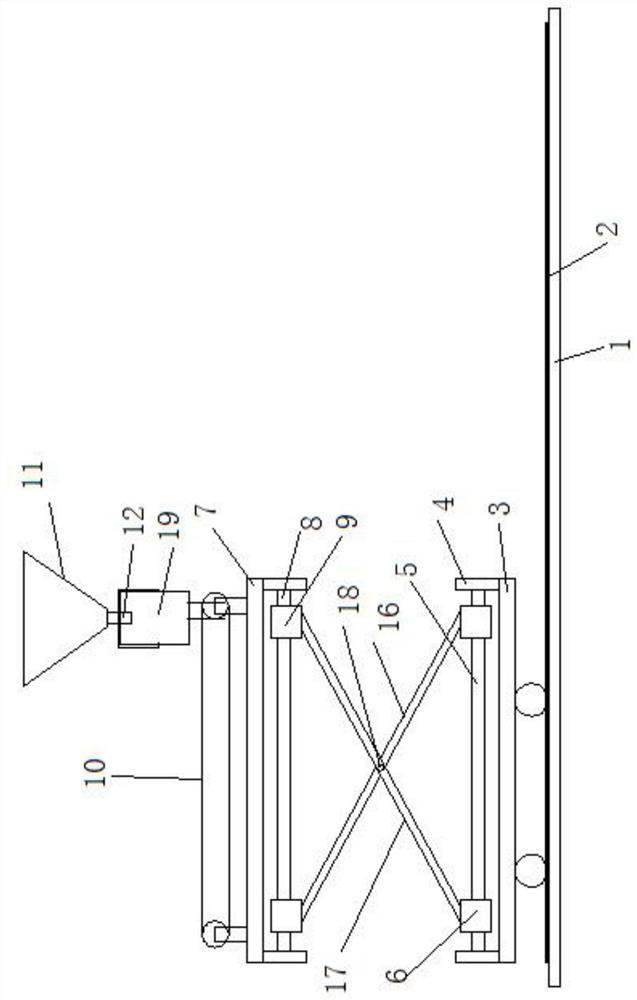

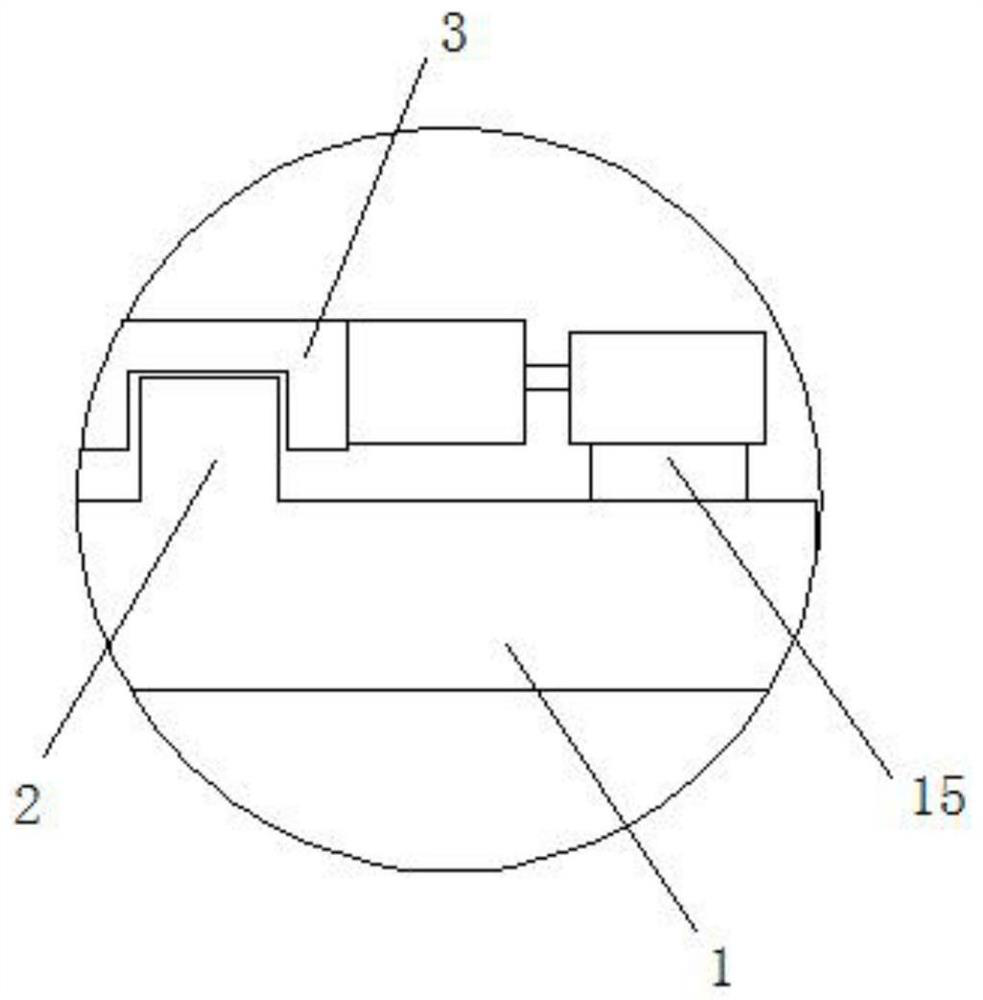

[0029] Figure 5 It is a schematic diagram of the cross-sectional structure of the endless conveyor belt.

[0030] Figure 6 It is a structural schematic diagram of the adjustable distance between two material guide plates.

[0031] Reference signs:

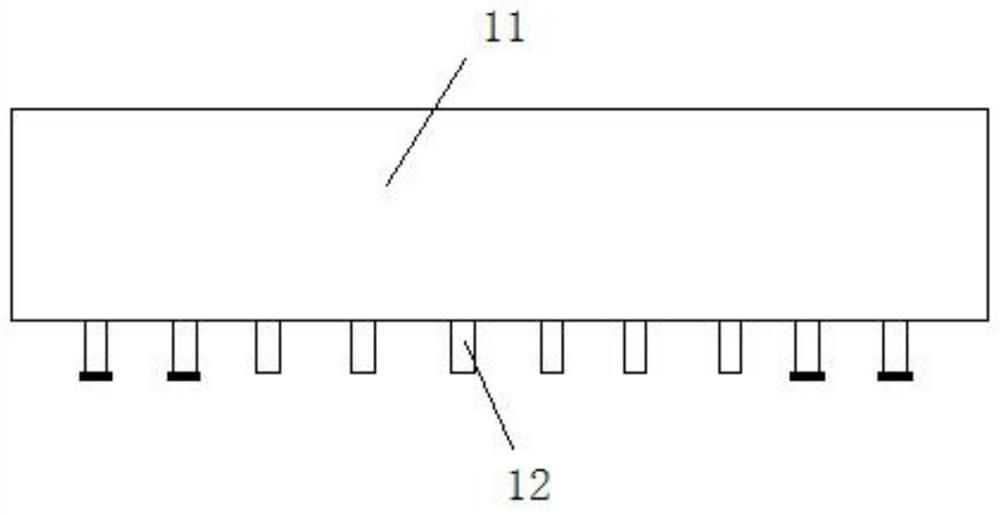

[0032] 1. Base; 2. Guide rail; 3. Moving seat; 4. Fixed support; 5. Screw rod one; 6. Slider one; 7. Fixed beam; 8. Screw rod two; 9. Slider two; 10. Circulating conveyor belt; 11. Uniform hopper; 12. Discharge pipe; 13. Feeding hoist; 14. Storage hopper; 15. Tooth plate; 16. Rod body one; 17. Rod body two; , conveyor belt one; 10-2, conveyor belt two; 10-3, positioning protrusion; 10-4, positioning groove; 10-5, retaining pin; 10-6, rib; 19, guide plate; 20 , Adjusting the screw rod; 21, the guide seat; 22, the circular lifting conveyor belt; 23, the lifting material plate; 24, the blocking plate.

Detailed ways:

[0034] See attached picture.

[0035] An automatic loading system for machine-made sand, including two bases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com