Method for determining an electrical output or electrical energy consumption of a spinning or winding machine and spinning or winding machine

A technology of winder, spinning machine, applied in the direction of spinning machine, electric power measurement by applying digital technology, open end spinning machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following detailed description, the same or at least equivalent features are used in the various embodiments or in the various figures with the same reference numerals. Accordingly, certain features are only elucidated when first mentioned or only in conjunction with the corresponding drawing. If these features are not separately explained again in connection with the other figures, their design and / or mode of operation correspond to that of the same or equivalent features already described. For the sake of clarity, when there are multiple identical features or components in the drawings, only one or several of these identical features are marked.

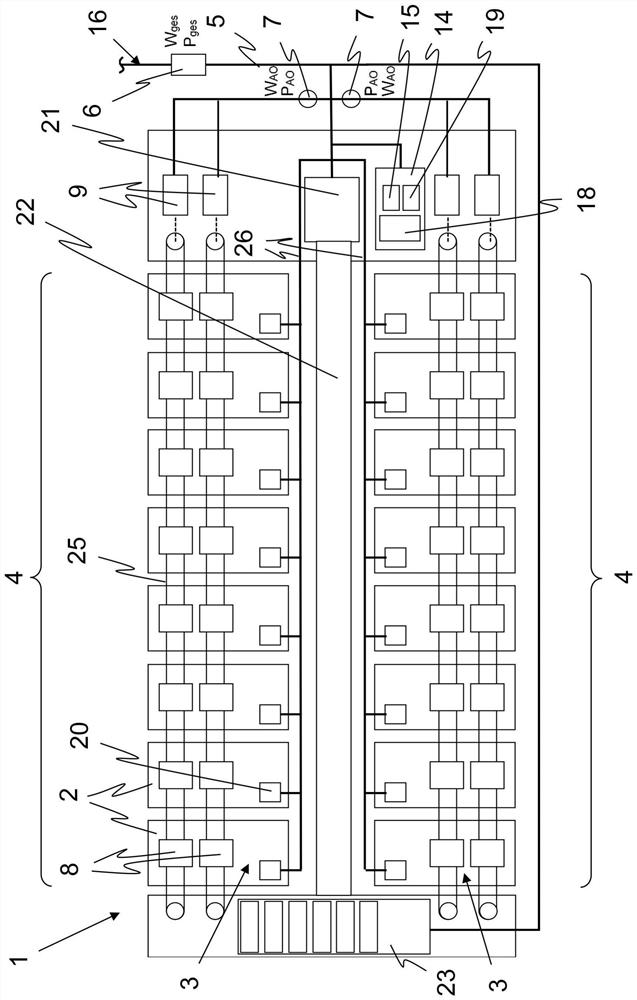

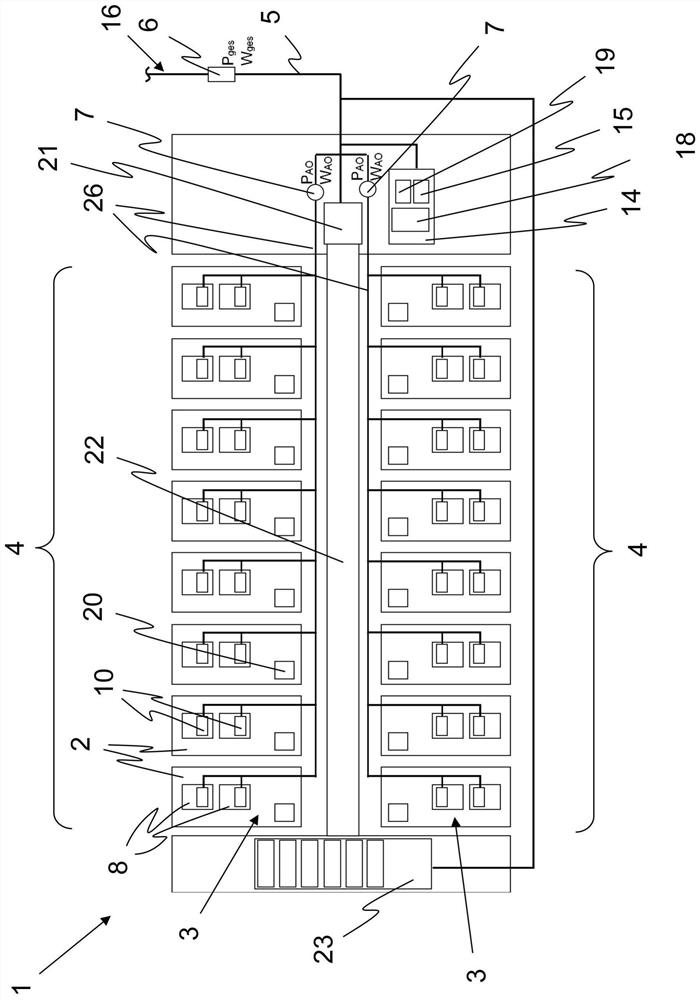

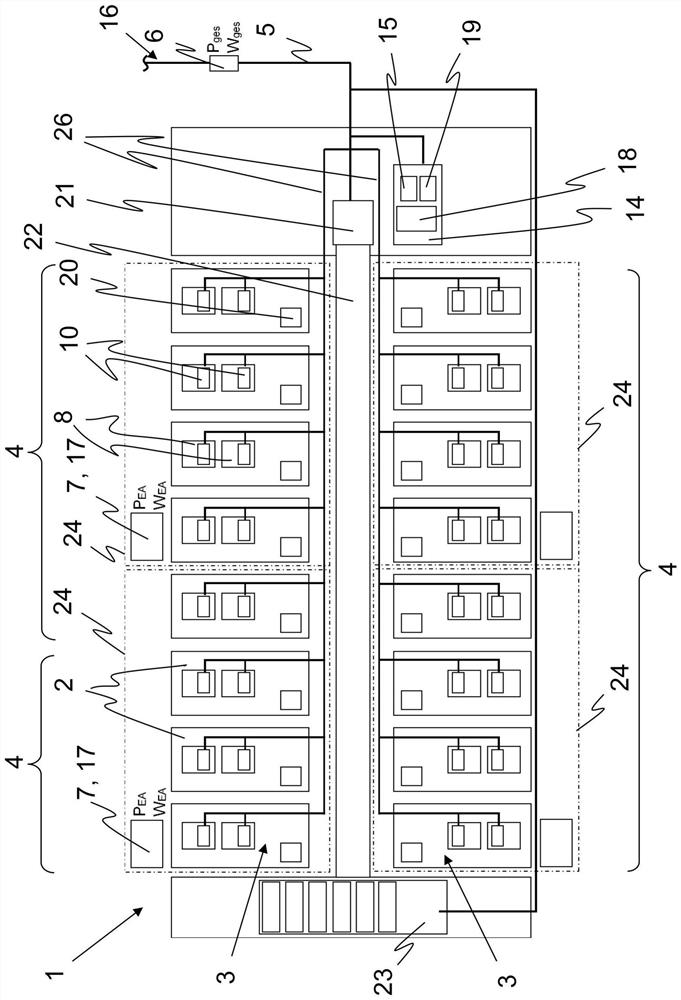

[0044] figure 1 A top view of a spinning or winding machine 1 with several stations 2 is shown. The number of stations 2 is usually much greater than if figure 1 Number of stations shown. The spinning or winding machine 1 may be any spinning or winding machine 1 having several stations 2 of the same type, but in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com