A method for measuring the size parameters of strain gauge sensitive grid

A technology of parameter measurement and sensitive grid, applied in the direction of measuring device, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problem that cannot describe the change of strain gage resistance, the size parameter of sensitive grid is subjective, and the sensitive grid is specific. Difficult to determine the boundary and other problems, to achieve the effect of enriching measurement methods, good size parameters, and reducing accidental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

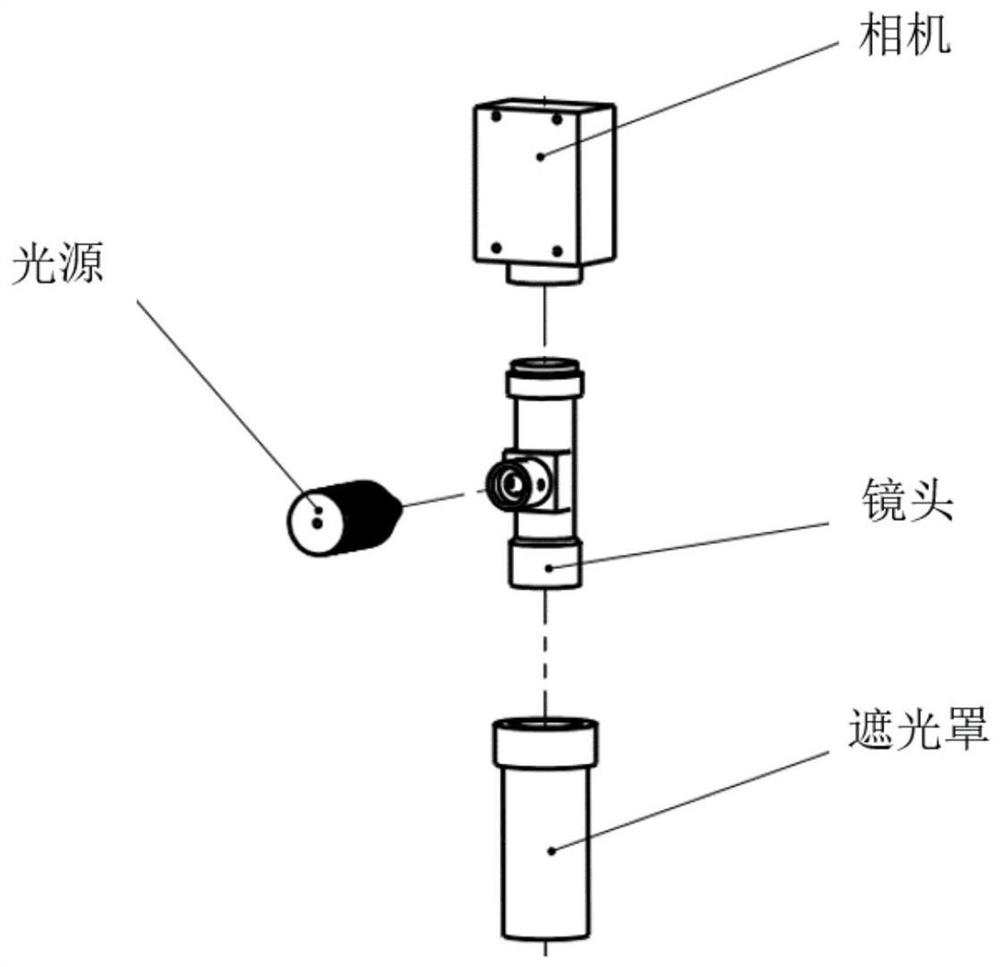

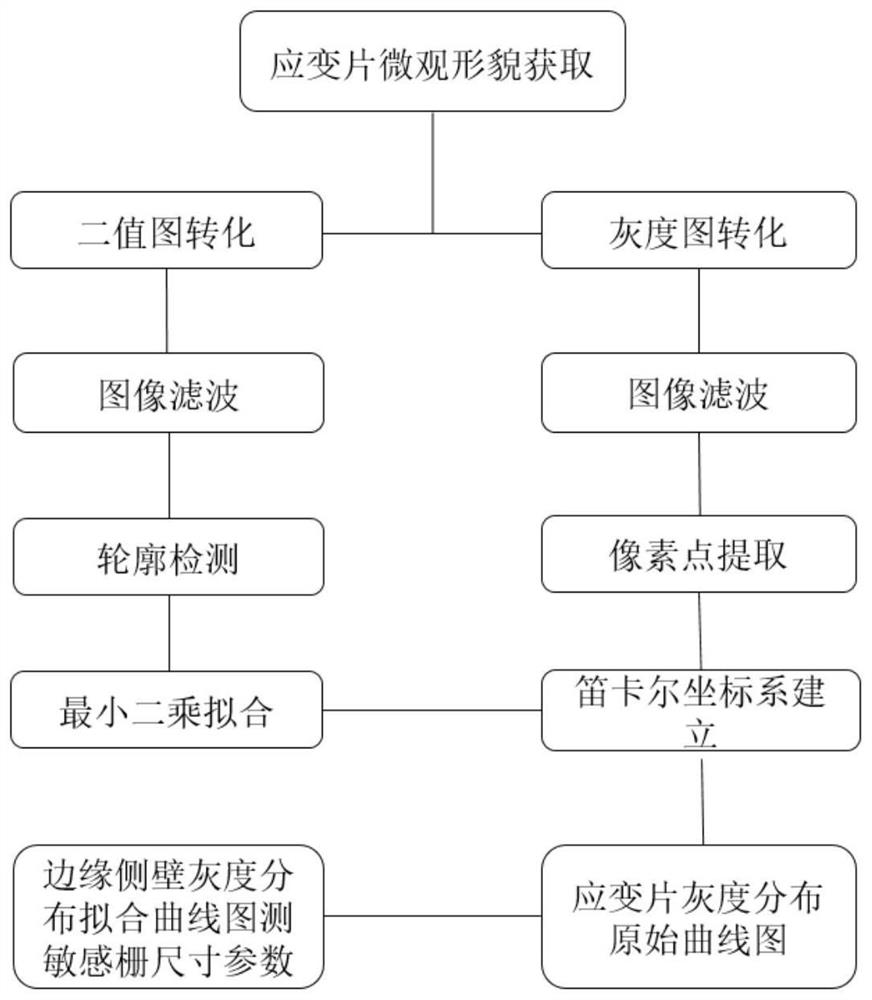

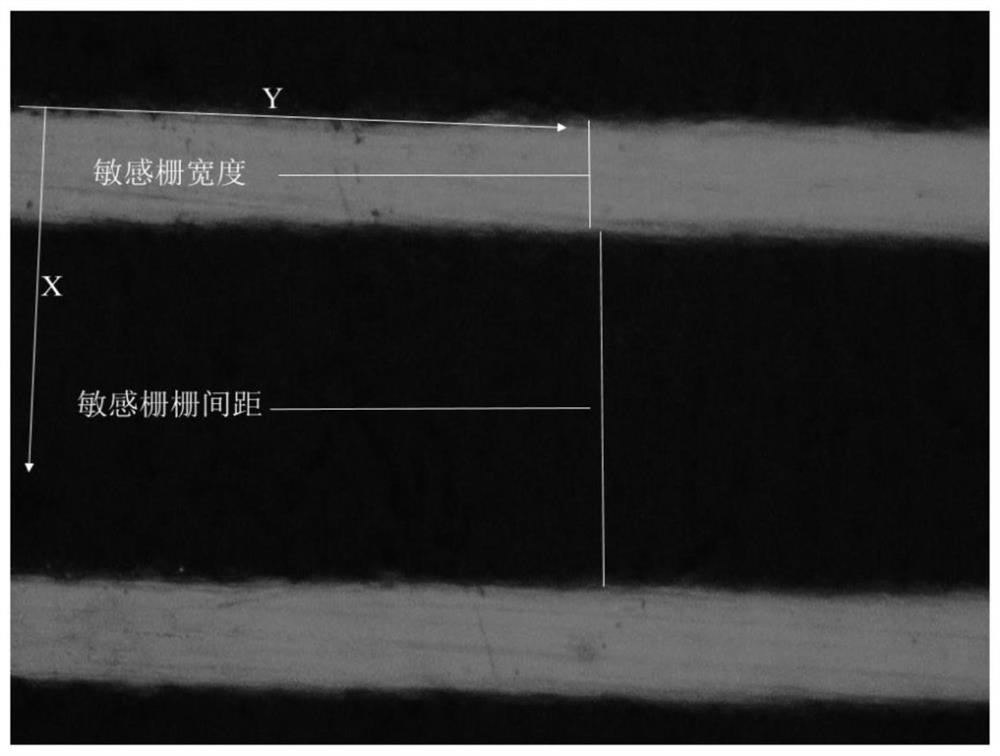

[0042] In this embodiment, a system is used to measure the size parameters of the strain gauge sensitive grid. The system mainly includes a strain gauge profile image capture device, a computer, and grayscale image conversion in the method based on the strain gauge profile extraction method, Binarization, image filtering, contour detection, contour point extraction, least square fitting, establishment of Cartesian coordinate system, normalization of gray value, establishment of original curve of gray distribution of strain gauge, edge side wall of strain gauge sensitive grid The software for establishing the gray distribution fitting curve and measuring the size parameters of the sensitive grid according to the characteristic point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com