Cement specific surface area test method based on split-type breathable cylinder

A technology of specific surface area and test method, used in permeability/surface area analysis, analysis of materials, suspensions and porous materials, etc. The effect of convenient sample preparation, good sealing performance and strong operability

Pending Publication Date: 2021-02-26

安徽省(水利部淮河水利委员会)水利科学研究院(安徽省水利工程质量检测中心站) +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In actual work, it is found that the quality of the sample is the most difficult to determine, because the national standard recommended void ratio is the data more than ten years ago, and the current cement production process has changed a lot, the void ratio is basically not muc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Login to View More

Abstract

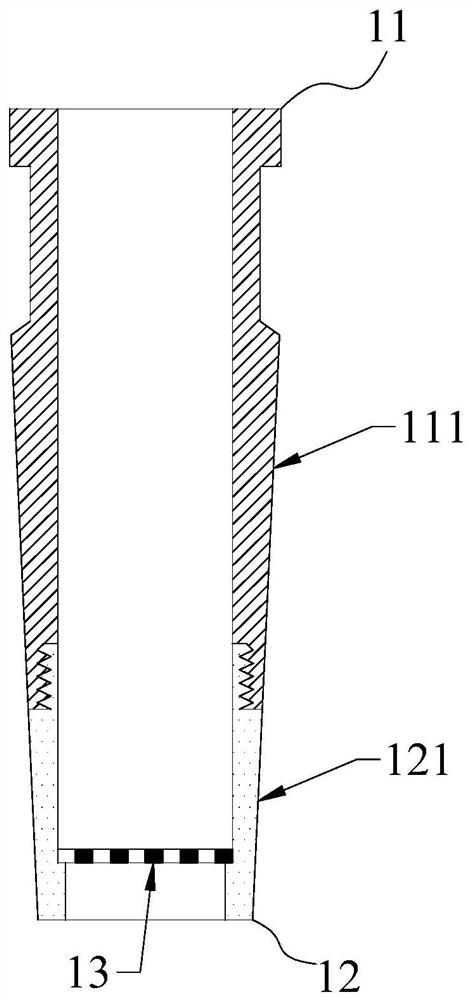

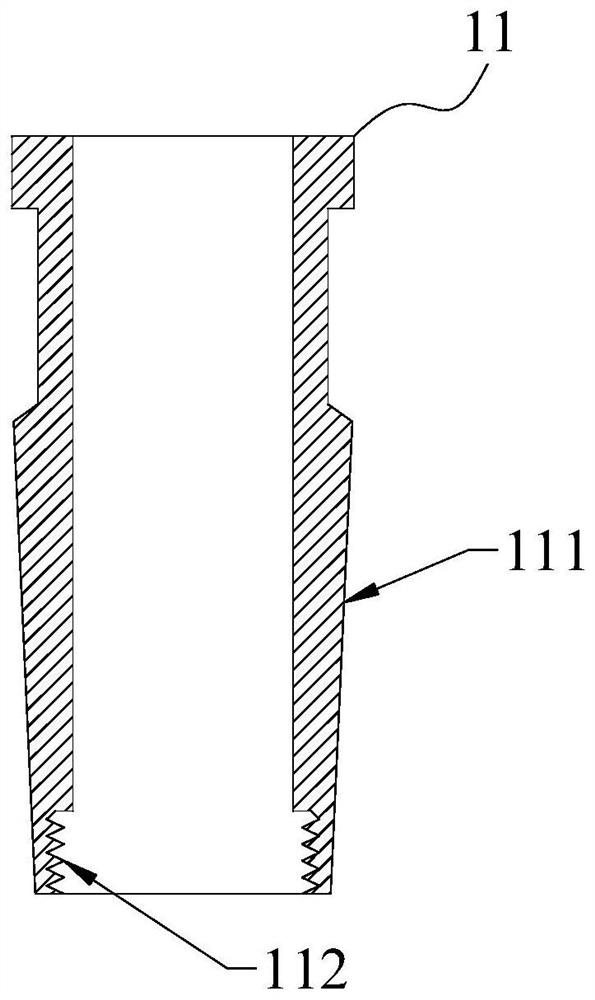

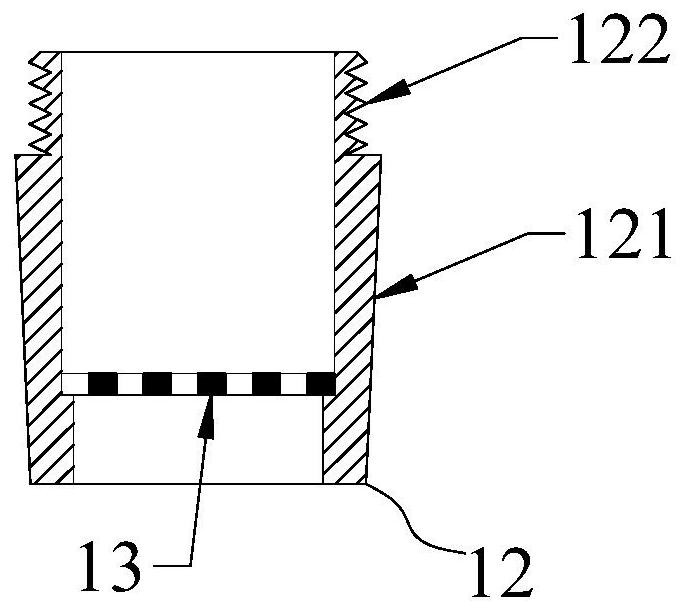

The invention relates to a cement specific surface area test method based on a split-type breathable cylinder. The cement specific surface area is measured by using a split-type breathable cylinder. The split-type breathable cylinder comprises an upper cylinder body, a lower cylinder body and a perforated plate, the periphery of the upper cylinder body is provided with a first conical surface, andthe lower end of the upper cylinder body is provided with an internal thread. A second conical surface is arranged on the periphery of the lower cylinder body, a boss used for supporting the perforated plate is arranged in the lower cylinder body, external threads matched with the internal threads are arranged on the upper portion of the lower cylinder body, and the lower portion of the upper cylinder body is in threaded connection with the upper portion of the lower cylinder body. According to the test method, the problem that the void ratios of different tested materials are not easy to determine is avoided, the test material is more convenient to prepare, sample preparation can be performed without considering the void ratios, and the test method has the obvious advantage of rapid andefficient sample preparation; and the operability is high, the height of the sample layer can be accurately controlled, errors can be effectively reduced, and the uncertainty of detection data is reduced.

Description

technical field [0001] The invention relates to a cement specific surface area test method based on a split-type ventilating cylinder, belonging to the technical field of cement fineness measurement. Background technique [0002] At present, the determination of cement specific surface area in the cement industry is based on GB / T 8074-2008 "Measurement method of cement specific surface area_Burner's method". This standard is suitable for determining the specific surface area of cement and the specific surface area suitable for this method is 2000-6000cm 2 / g of other powdery materials, the measurement principle is to measure the specific surface area of cement based on the change of flow velocity caused by the different resistance when a certain amount of air passes through the cement layer with a certain porosity and fixed thickness. [0003] When measuring the specific surface area, a certain quality of cement sample should be filled in the air-permeable cylinder. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/08

CPCG01N15/088

Inventor 刘军董献国李亚南胡晓曼庄菲鲁磊张杰王雷李泽君张文仲解文艳音正兵吴志德陈彩虹孙茹

Owner 安徽省(水利部淮河水利委员会)水利科学研究院(安徽省水利工程质量检测中心站)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com