Double-locking device with auxiliary support and high-capacity switch equipment

A technology of auxiliary support and locking device, which is applied in the direction of high-voltage/high-current switches, electric switches, and air switch parts, etc. The effect of uneven force, reducing design difficulty and improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

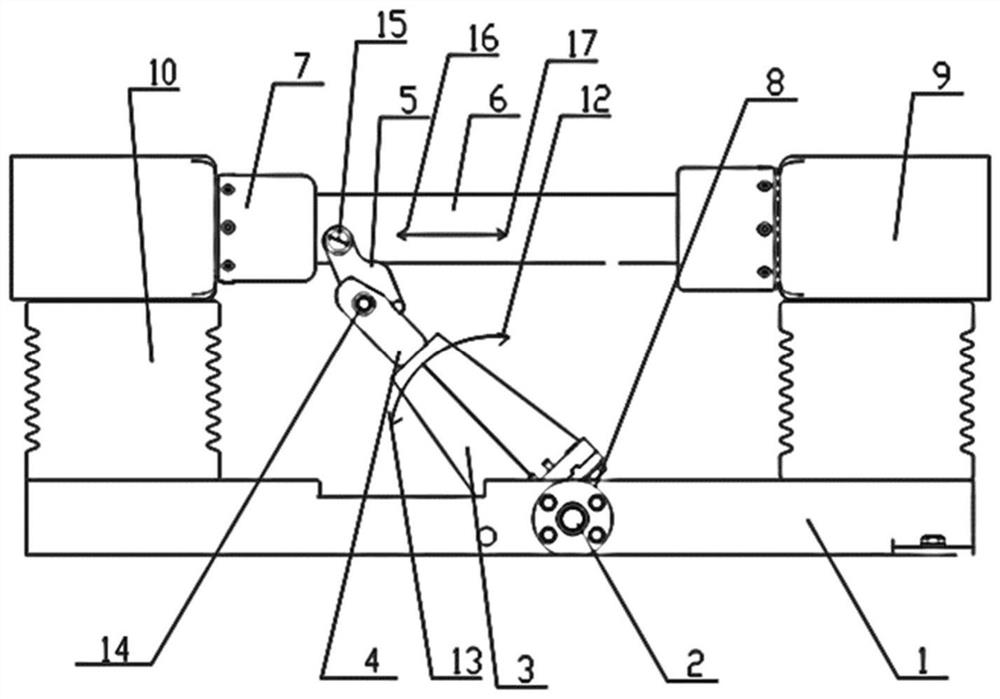

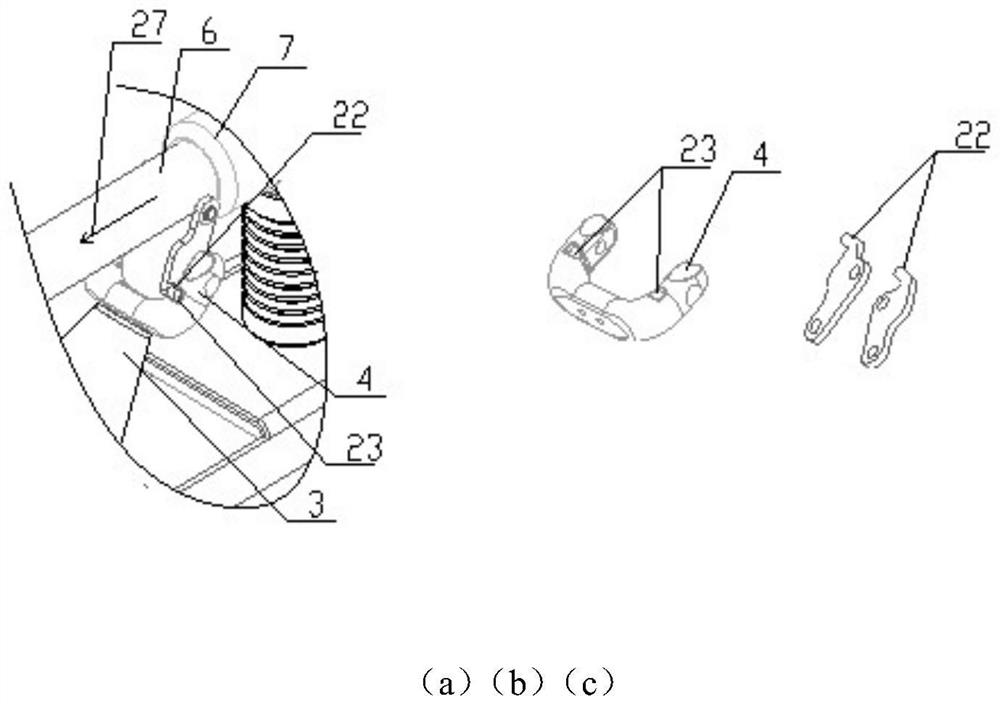

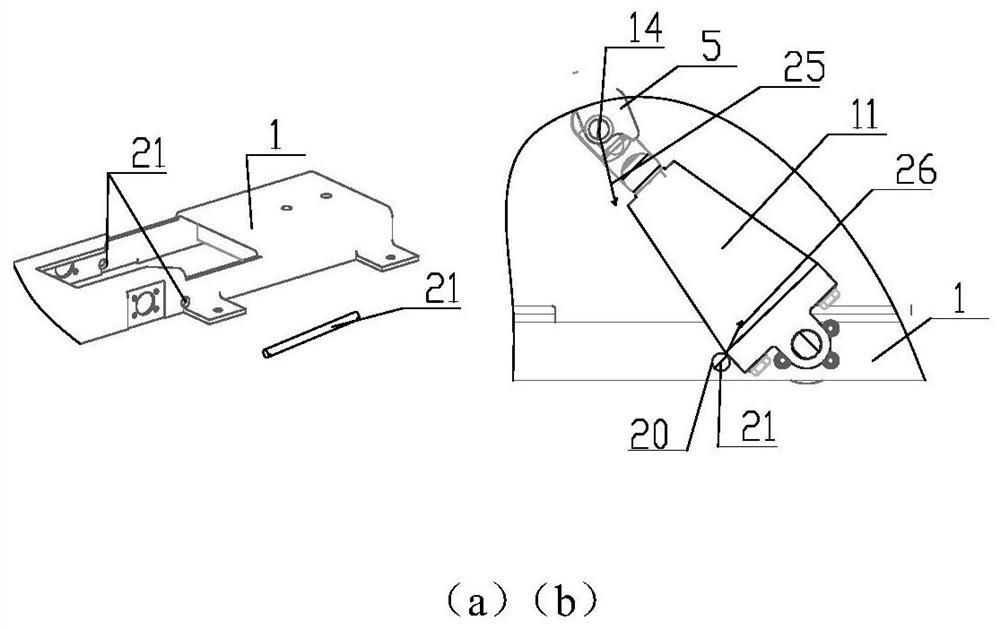

[0030] Such as figure 1 As shown, the present invention provides a double locking device with auxiliary support, the switch is in the closed state, the rotating shaft 2, the insulating rotor 3, and the U-shaped support 4 are installed as a crank arm 11, and the rotating shaft 2 is installed on the support on the support 1. At the seat circle center 8, the crank arm 11 rotates with the support circle center 8 as the axis to realize the opening movement direction 12 and the closing movement direction 13; the U-shaped support 4 and the connecting plate 5 are connected by the first pin rod 14, and the connecting plate 5 It is connected with the movable contact 6 through the second pin rod 15; when the crank arm 11 moves in the opening movement direction 12 and the closing movement direction 13, the U-shaped support 4 drives the connecting plate 5 to move through the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com