Shoemaking vamp drilling device capable of automatically drilling holes and collecting waste materials in centralized mode

A drilling device and waste technology, applied in shoemaking machinery, footwear, applications, etc., can solve the problems of not having the technical solution for replacing the drill bit, low efficiency of the drill bit, unable to meet the processing needs of users, etc., and achieve high-efficiency automatic The effect of returning material collection and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

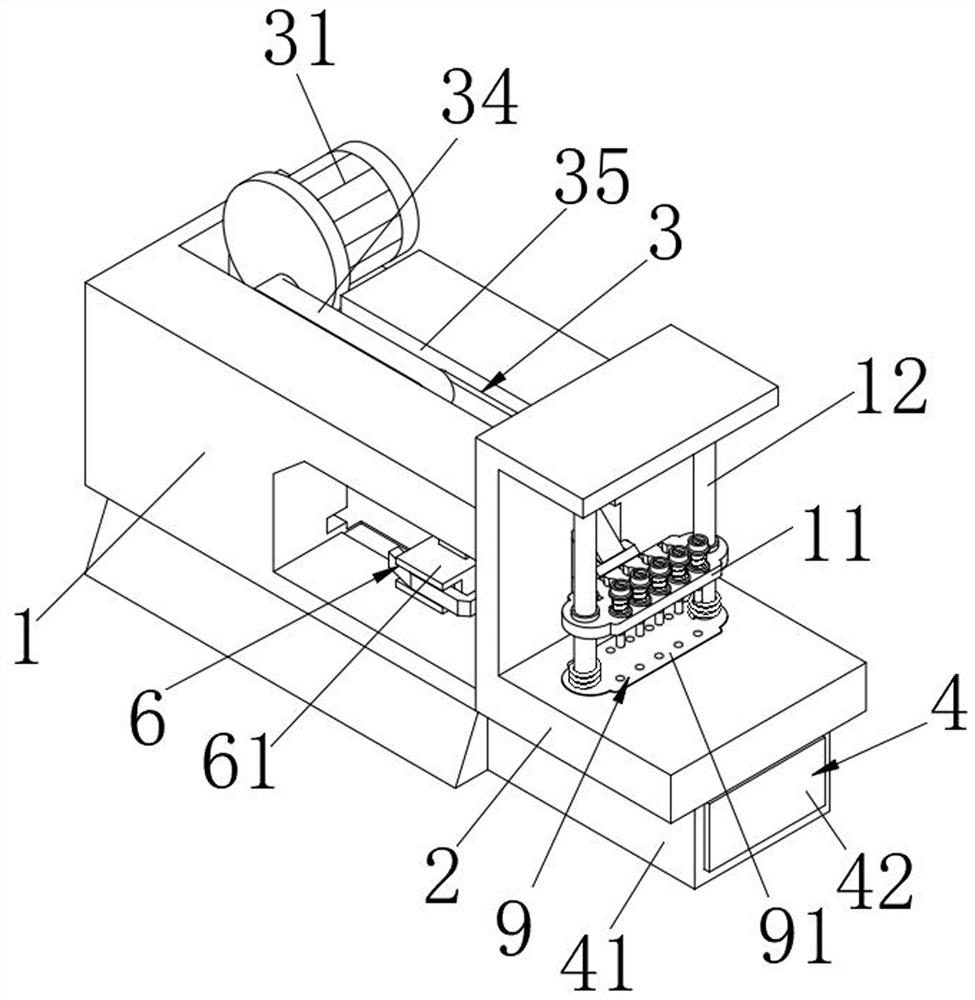

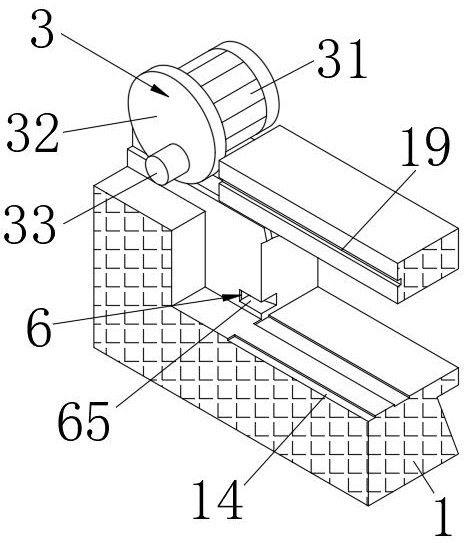

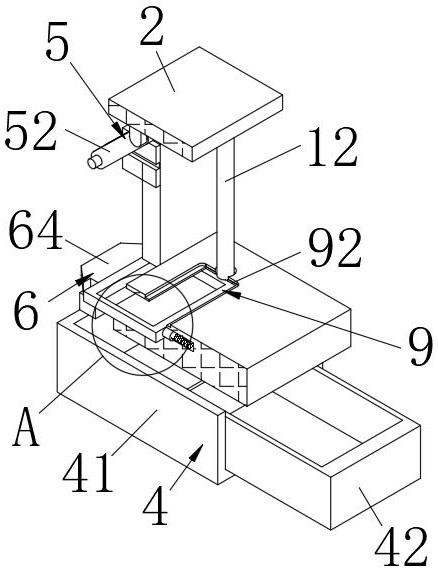

[0036] see Figure 1-7 , the present invention provides a technical solution: an upper drilling device for shoemaking that automatically punches holes and collects waste materials in a concentrated manner, including a body 1, a processing table 2 is fixedly connected to the right side of the body 1, and the bottom of the inner cavity of the processing table 2 The front side and the rear side of the body are fixedly connected with a guide post 12, the surface of the guide post 12 is slidably connected with a lower pressing plate 11, the top of the body 1 is provided with a drive mechanism 3, and the bottom of the processing table 2 is provided with a storage mechanism 4, the storage mechanism 4 Including a box body 41 fixedly connected to the bottom of the processing table 2, the inner cavity of the box body 41 is slidably connected with a drawer box 42, and the bottom of the inner cavity of the processing table 2 is provided with a return bin 43, and the inner cavity of the ret...

Embodiment 2

[0043] see Figure 1-7 , the present invention provides a technical solution: an upper drilling device for shoemaking that automatically punches holes and collects waste materials in a concentrated manner, including a body 1, a processing table 2 is fixedly connected to the right side of the body 1, and the bottom of the inner cavity of the processing table 2 The front side and the rear side of the body are fixedly connected with a guide post 12, the surface of the guide post 12 is slidably connected with a lower pressing plate 11, the top of the body 1 is provided with a drive mechanism 3, and the bottom of the processing table 2 is provided with a storage mechanism 4, the storage mechanism 4 Including a box body 41 fixedly connected to the bottom of the processing table 2, the inner cavity of the box body 41 is slidably connected with a drawer box 42, and the bottom of the inner cavity of the processing table 2 is provided with a return bin 43, and the inner cavity of the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com