Universal platform for butting front and rear ends of crane frame

A common platform, front-end and back-end technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of lack of docking platform, cumbersome and inconvenient loading and unloading of the docking platform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

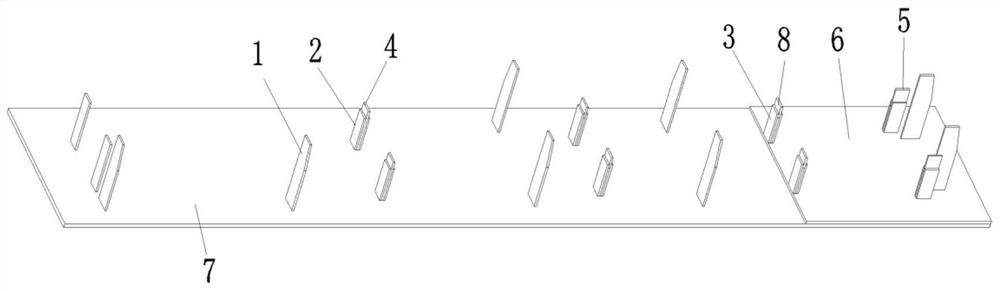

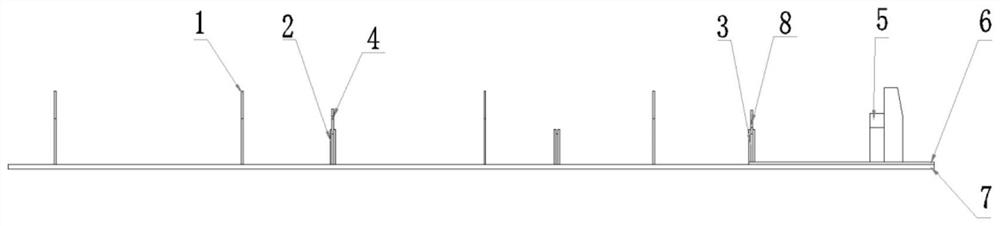

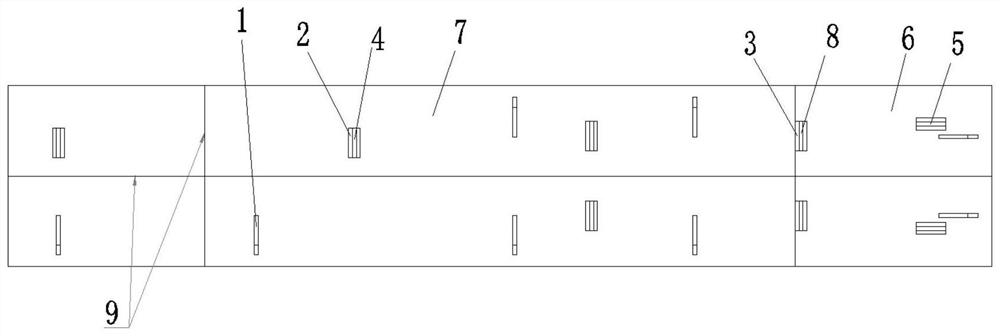

[0030] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0031] according to Figure 1-5 As shown, the present invention provides a common platform 7 for docking the front and rear ends of the crane frame, including: a platform 7, a base plate 6 and an adjustment block group, the platform 7 is a square panel, and one side of the platform 7 is provided with a The base plate 6 , the upper surface of the base plate 6 and the platform 7 are all provided with an adjusting block set, and the adjusting block set is used for erecting the workpiece 10 .

[0032] When in use, the adjusting block group can be replaced according to crane frames of different sizes and models, so that the platform 7 can be replaced at any time accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com