Support-free primary and secondary beam system, construction method thereof and prefabricated superposed main beam notch mold

A technology of primary and secondary beams and composite beams, applied in the direction of joists, girders, truss beams, etc., can solve the problems of insufficient shear bearing capacity and the inability to realize prefabricated composite beams without support, etc., and achieve low cost of mold opening, transmission Reliable and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing description:

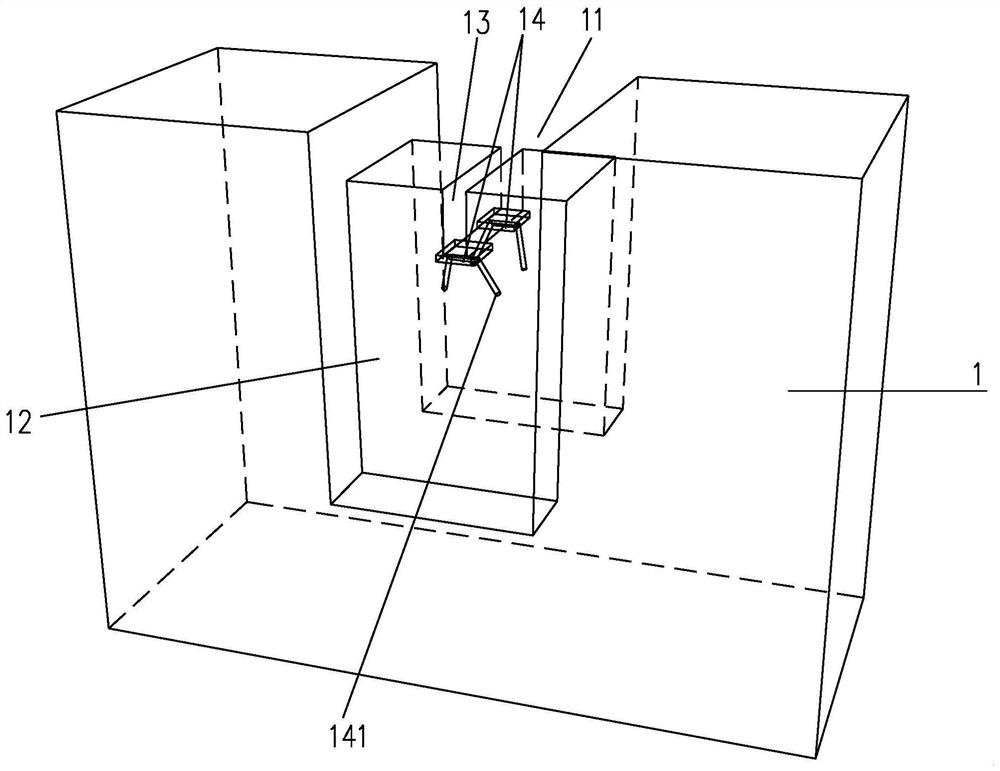

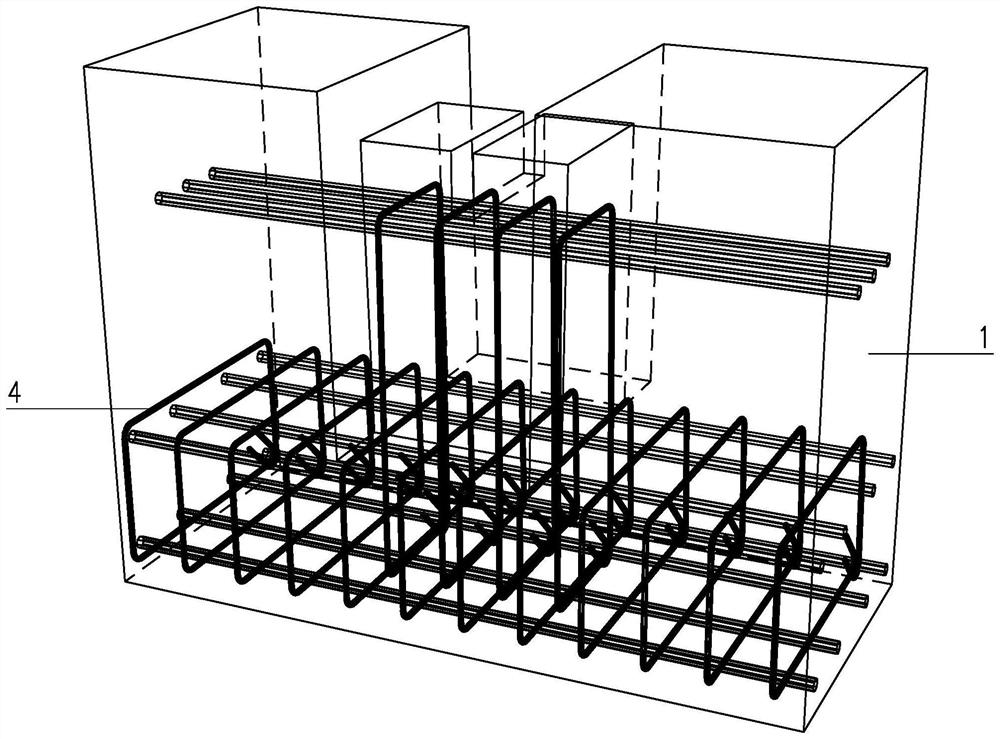

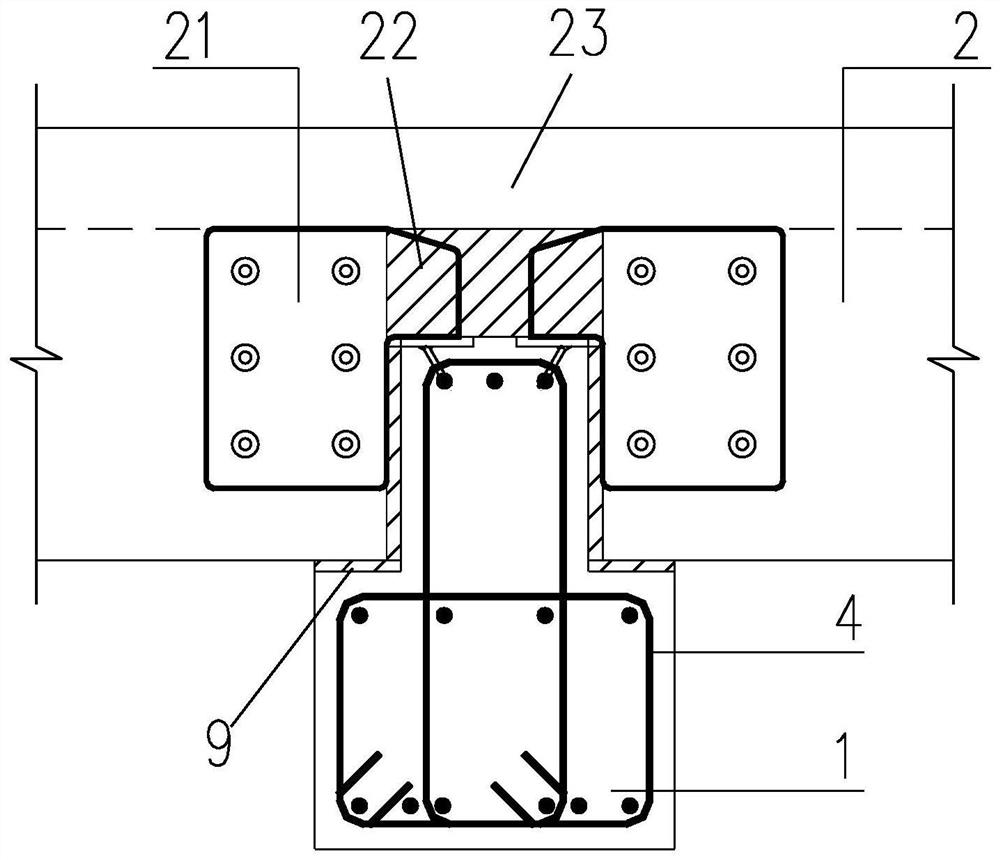

[0032] Such as Figure 1-4 Shown: the present invention relates to a support-free primary and secondary beam system, including a prefabricated laminated main beam 1 and a prefabricated laminated secondary beam 2;

[0033] The prefabricated laminated girder 1 is provided with a plurality of through notches 11, and a support block 12 is provided in the notches 11;

[0034] The support block 12 is provided with a steel bar 4 extending into the prefabricated laminated main beam 1, so that the support block 12 and the prefabricated laminated main beam 1 are integrated;

[0035] The upper surface of the support block 12 is provided with a groove 13, and the bottom of the groove 13 is provided with a pressure-bearing steel plate 14;

[0036] The end of the prefabricated laminated secondary beam 2 is provided with a pre-embedded steel connector, the pre-embedded steel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com