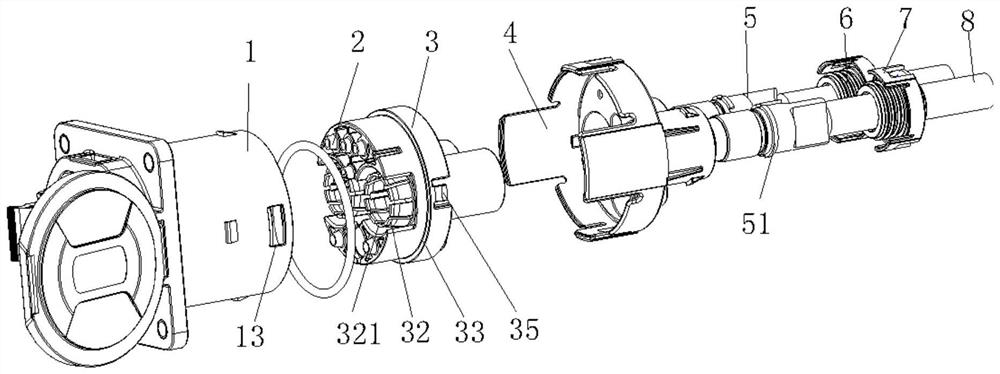

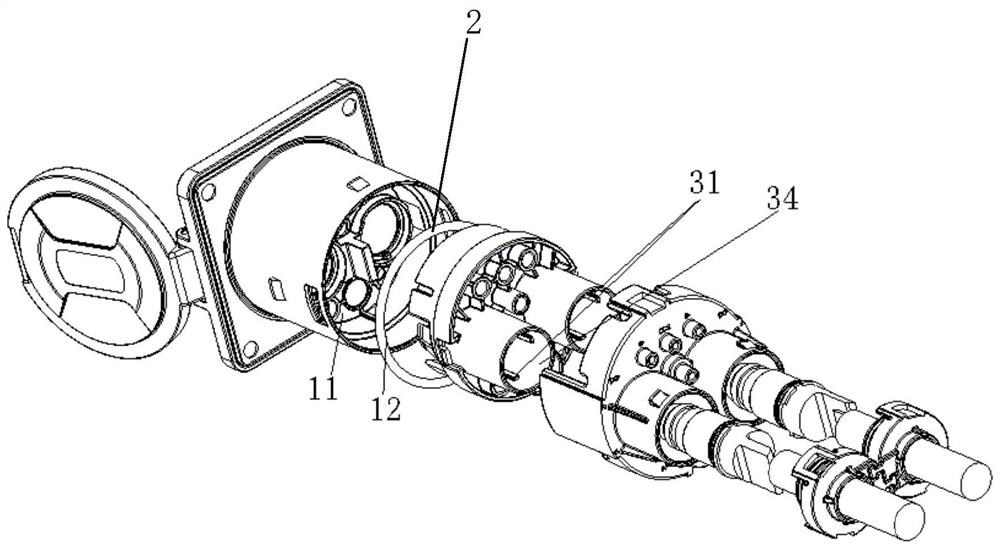

a charging connector

A charging connector and connector technology, which is applied in connection, charging stations, electric vehicle charging technology, etc., can solve the problems of high design requirements, low mass assembly production efficiency, difficult terminal disassembly process, etc., and achieve fast blind assembly and disassembly , high production efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

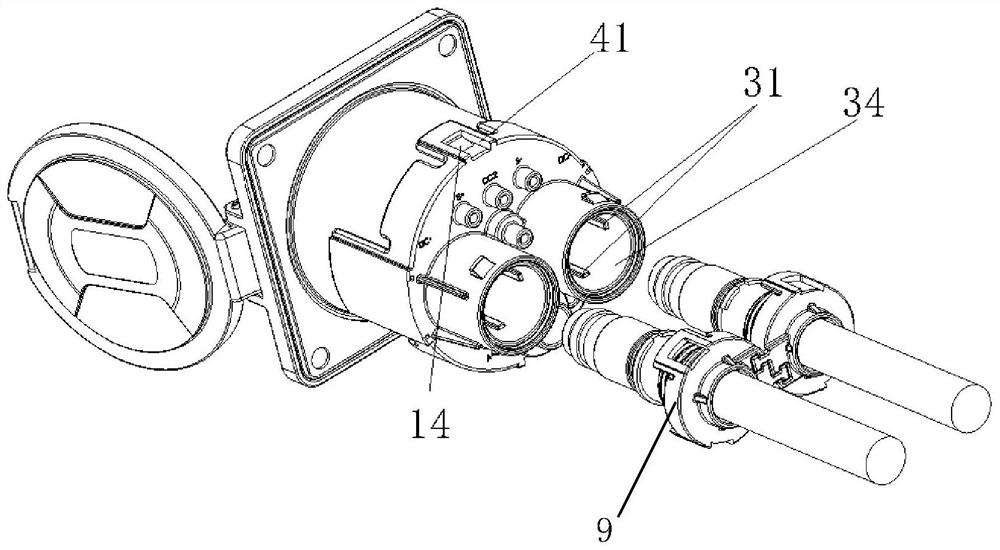

[0032] The second specific embodiment is as follows:

[0033] On the basis of the specific embodiment 1, as an alternative, the pressing plate 3 can also be limited in the accommodating cavity 11 by the tail cover 4. At this time, it is not necessary to provide the snap structure, and the tail cover can be removed from the connector housing. After being disassembled, the pressing plate and the terminal part can be directly taken out, and then the elastic tooth piece 321 of the elastic tooth structure hole can be deformed by the tooling, so that the terminal part can be withdrawn to the rear end, and the whole terminal part can be completed.

[0034] Further, the charging connector of the present invention is also provided with a temperature monitoring mechanism. The temperature monitoring mechanism includes a accommodating groove 101, a temperature monitoring device 102, a sealing member 103 and a monitoring device fixing member 104. The accommodating groove 101 is opened on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com