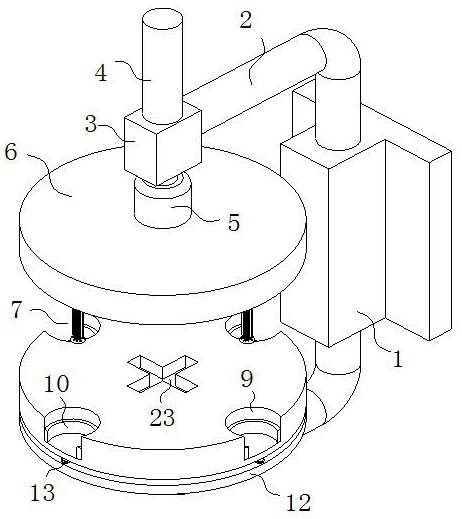

Shaking-up equipment for chemical production

A technology of medicine and equipment, applied in the field of shaking equipment for medicine production, can solve the problems of reduced production efficiency, foaming of medicine liquid, easy adhesion of foam to the bottle mouth and equipment, etc. , to ensure the effect of mixing and mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

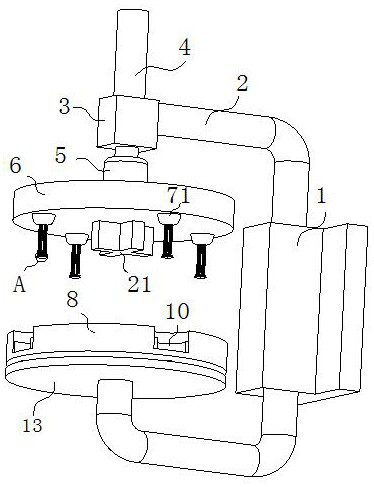

Method used

Image

Examples

specific Embodiment approach

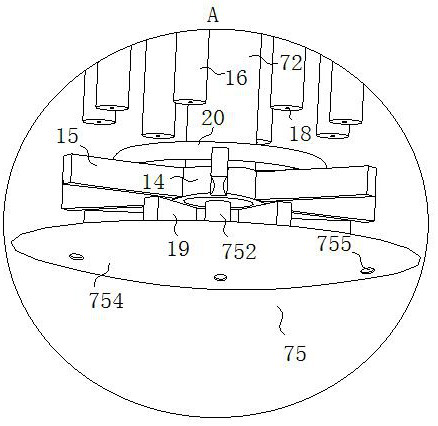

[0033]As a specific embodiment of the present invention, a fixed disk 12 is sleeved on the curved rod 2 at the bottom of the lower rotating disk 8, and a plurality of magnetic disks 13 are evenly distributed on the top of the fixed disk 12 along the circumferential direction. The gaps 9 correspond one to one; the outer side of the center rod 72 is sleeved with a bearing 14, and the surface of the bearing 14 is provided with a plurality of impellers 15, the impellers 15 are located between the outlet hole 74 and the cone 753, and the free end of one of the impellers 15 is sprayed. There is a magnetic coating; during the simultaneous rotation of the upper rotating disk 6 and the lower rotating disk 8, there are a plurality of magnetic disks 13 corresponding to the notch 9 on the top of the fixed disk 12 at the bottom of the lower rotating disk 8, when the central rod 72 and During the rotation of the medicament bottle, there is a rotatable impeller 15 at the bottom of the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com