Camber control method based on slab center line deviation analysis

A control method and camber technology, applied in the field of control, can solve the problems that the bouncing data cannot be very accurate, the influence of control is not considered, and the stiffness test cannot be done, so as to reduce adverse effects, reduce the degree of bending, and improve the degree of camber Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

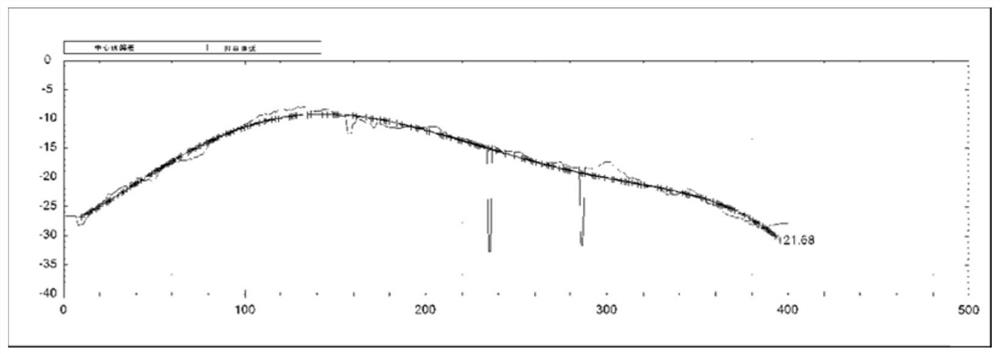

[0100] Assume that the centerline deviation data measured according to step 1) and step 2) are as follows Figure 5As shown in , all the data are fitted with a quadratic polynomial, and the fitted data result is:

[0101] y=-0.0012752x 2 +0.65984x-79.7912

[0102] Since its quadratic coefficient -0.0012752 is less than 0, the parabola opens downward.

[0103] Assume that opening up means the head is bent towards the driving side and opening down means the head is bent towards the operating side. Then the opening of this slab is downward, which means that the head is bent to the operation side, so the operation side should be pressed more accordingly. The actual pressure needs to be calculated according to the degree of bending.

[0104] Use a 5th degree polynomial to fit the curve. The fitted curve can effectively filter abnormal data. For the fitted curve represented by the "+" curve in the figure, the equation after the 5th degree polynomial fitting is as follows:

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com