Foaming process of refrigerator

A refrigerator and process technology, used in household appliances, other household appliances, household components, etc., can solve the problems of poor thermal conductivity of products, high cost of foaming materials, long time, etc., and achieve shorter curing time and surface crusting. The effect of improving and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

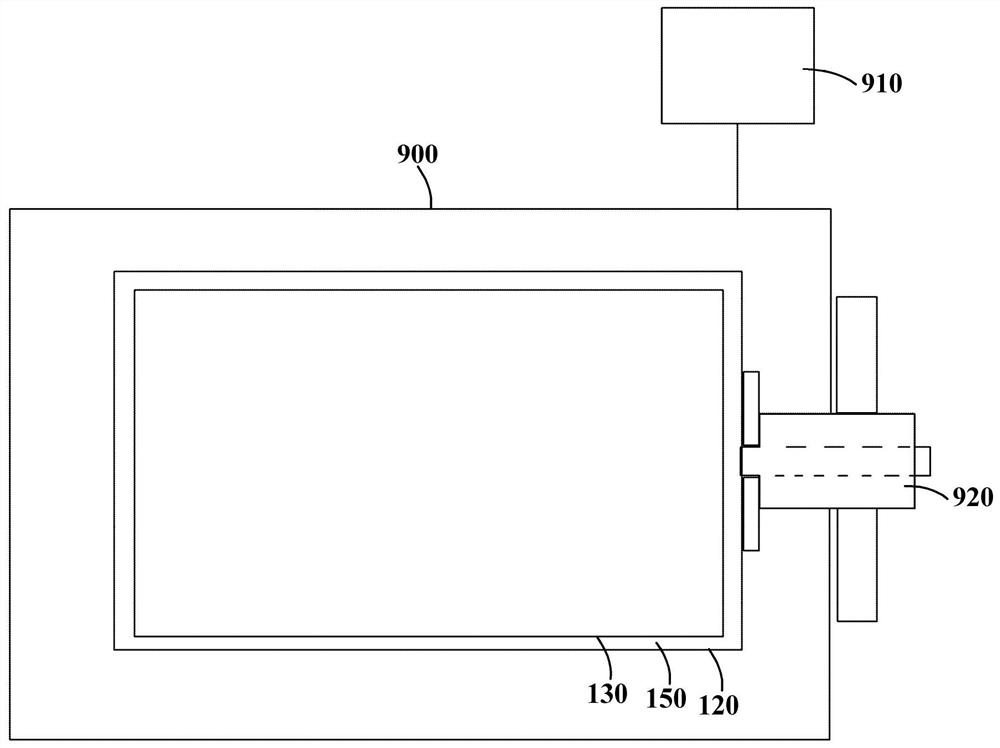

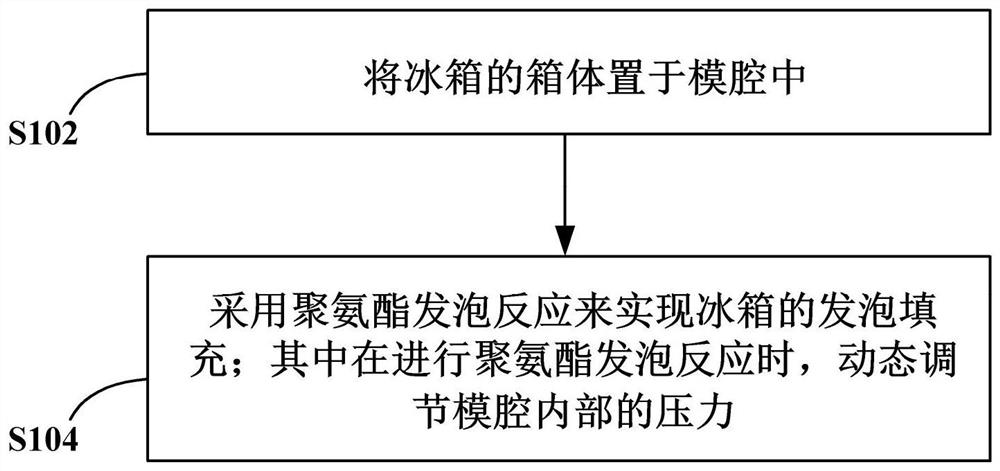

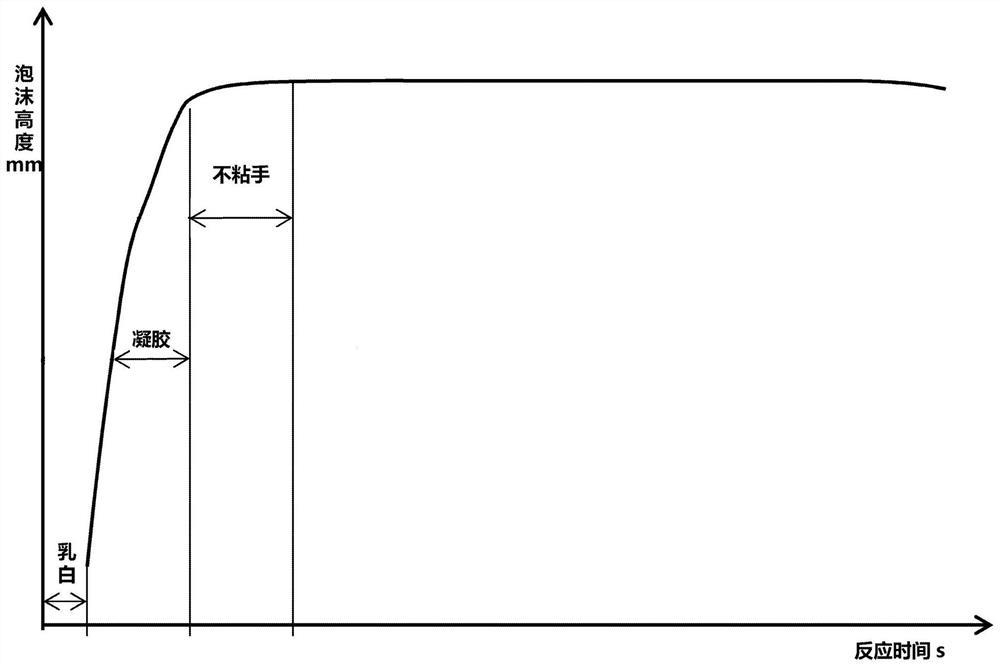

[0037] figure 1 It is a schematic diagram of the device when performing the foaming process of the refrigerator 100 according to an embodiment of the present invention. figure 2 is a schematic flowchart of the foaming process of the refrigerator 100 according to an embodiment of the present invention. The refrigerator 100 in the embodiment of the present invention includes a box body 110 and a door body (not shown in the figure). The box body 110 includes an outer shell 120 and an inner tank 130 . The interior of the liner 130 defines a storage space 140 . A foaming space 150 is defined between the inner tank 130 and the outer shell 120 . The storage space 140 constitutes one or more storage compartments. The door body is arranged on the front side of the storage compartment for opening and closing the storage compartment. The number and structure of storage compartments can be configured according to requirements. For example, the storage compartment includes a refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com