Throat lozenge tabletting forming machine

A molding machine and tableting technology, which is used in material molding presses, presses, and devices for making medicines into special physical or ingesting forms, etc. Inconvenient materials and other problems, to achieve the effect of novel structure, improved production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

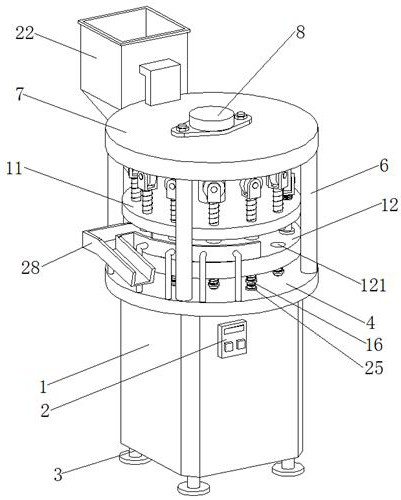

[0035] This embodiment 1 discloses a kind of lozenge lozenge tablet forming machine, with reference to the attached figure 1 , its main structure includes a chassis 1, on the outer surface of the chassis 1 is provided with a control switch 2, the control switch 2 is used to control the start and stop of electrical components in the whole device, and a number of shock-absorbing feet 3 are set on the lower surface of the chassis 1.

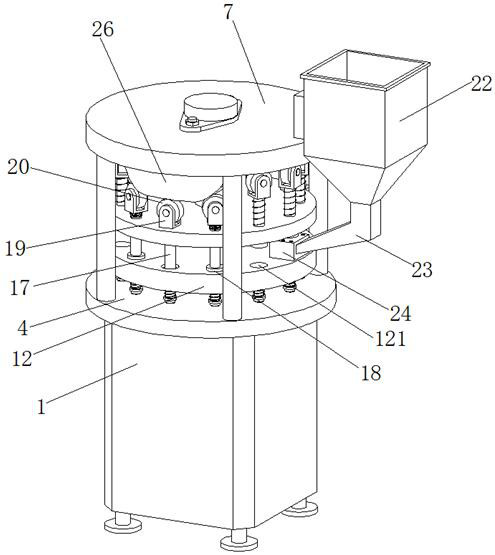

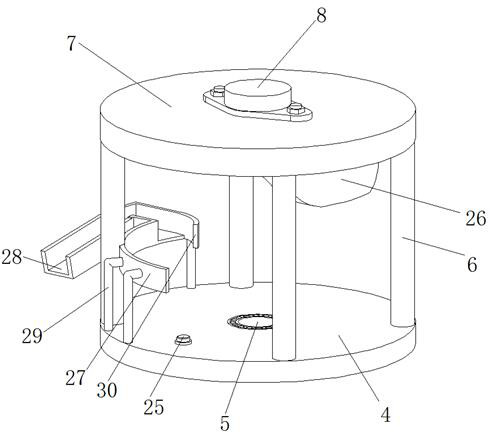

[0036] Reference attached figure 1 , attached image 3 , the upper surface of the cabinet 1 is fixedly connected with a circular lower plate 4, a bearing 5 is arranged at the center of the lower plate 4, and four columns 6 are arranged on the outer edge of the upper surface of the circular lower plate 4. A column 6 is fixed on the upper surface of the lower plate 4 in an annular array, and a circular top plate 7 is fixedly connected to the upper ends of the four columns 6 together, and a bearing seat 8 is arranged at the center of the top plate 7 ....

Embodiment 2

[0043] Embodiment 2 discloses an improved laryngeal lozenge tablet forming machine based on Embodiment 1. Refer to the attached Figure 4 And attached Figure 5 First of all, the same parts of this embodiment 2 and embodiment 1 will not be described again, the difference is that this embodiment 2 is also sleeved on the first guide rod 14 between the non-metallic end block 15 and the lower turntable 12 There is a booster spring 31, and the upper and lower ends of the booster spring 31 are connected with the lower turntable 12 and the non-metallic end block 15 respectively.

[0044] The arrangement of the booster spring 31 in the second embodiment has two effects. One, prevent the first powerful magnet 16 from being adsorbed on the lower surface of the lower turntable 12 after being jacked up, because the setting of the booster spring 31 can make the first powerful magnet 16 return to its original state after removing the repelling effect of the same pole. Its two; through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com