Structure and printing method of embedding rfid electronic tags in books

An electronic label, book technology, applied in printing, book binding, adhesives for binding, etc., can solve the problems of insufficient paste concealment, easy to be found, high cost, and save labor cost, not easy to wear and tear. The effect of tearing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

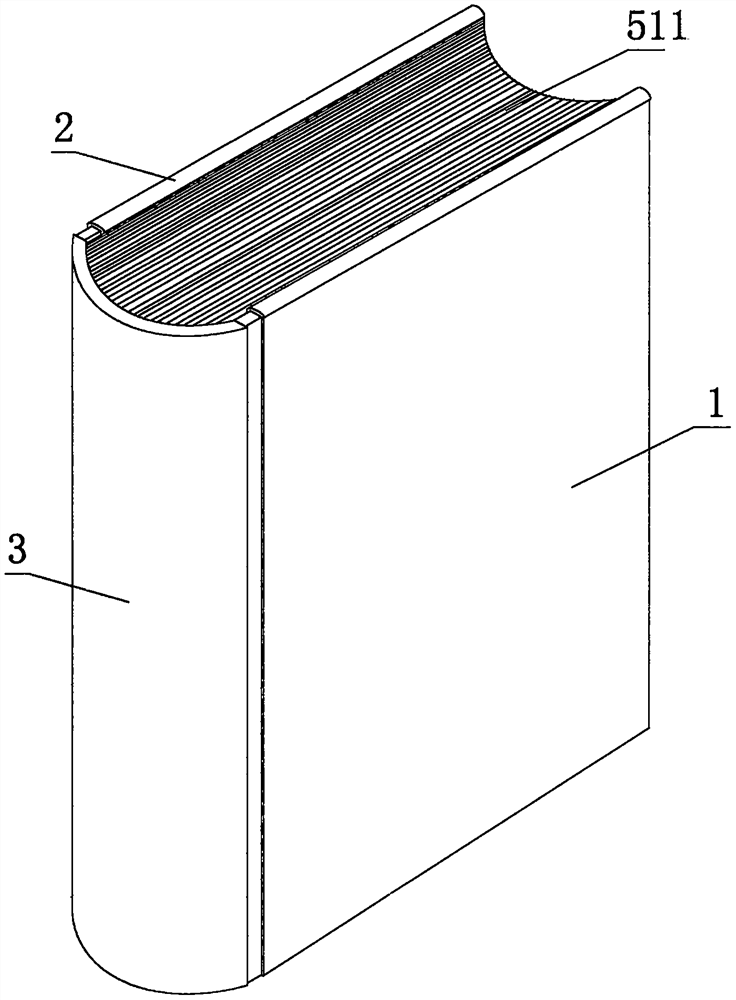

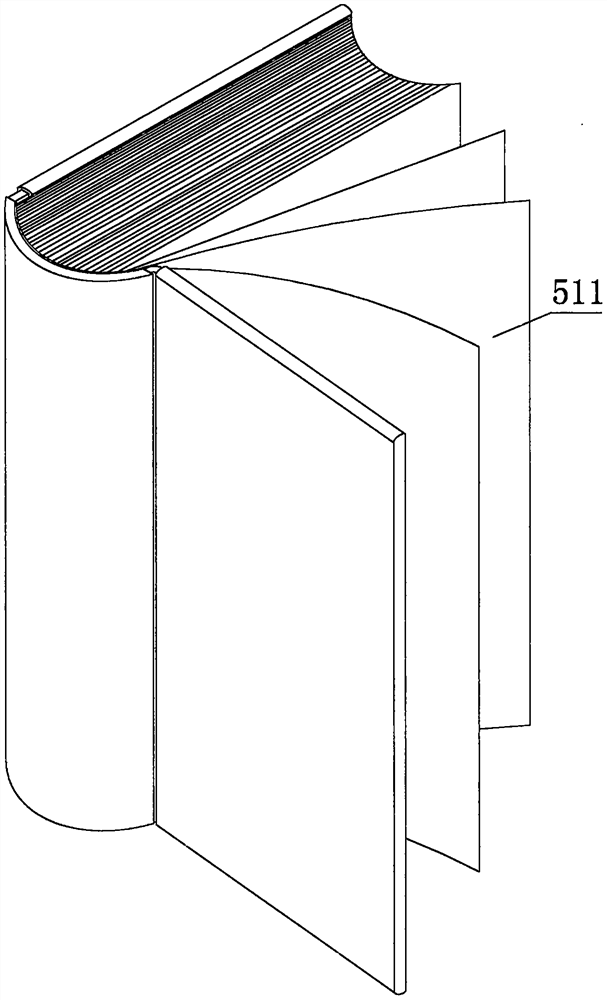

[0030] see Figure 1-2 , the structure of embedding the RFID electronic tag in the book, including the cover 1, the back cover 2 and the spine 3, the spine 3 includes a front ridge 31 and a rear ridge 32, the front ridge 31 and the rear ridge 32 are attached to each other, and the front ridge 31 and the rear ridge 32 The top and bottom of the book are connected to each other as a whole, an arc hole 4 is formed between the front ridge 31 and the rear ridge 32, so that the spine 3 can be penetrated, and the middle part of the front ridge 31 is bonded with a plurality of sheets 511 by adhesive.

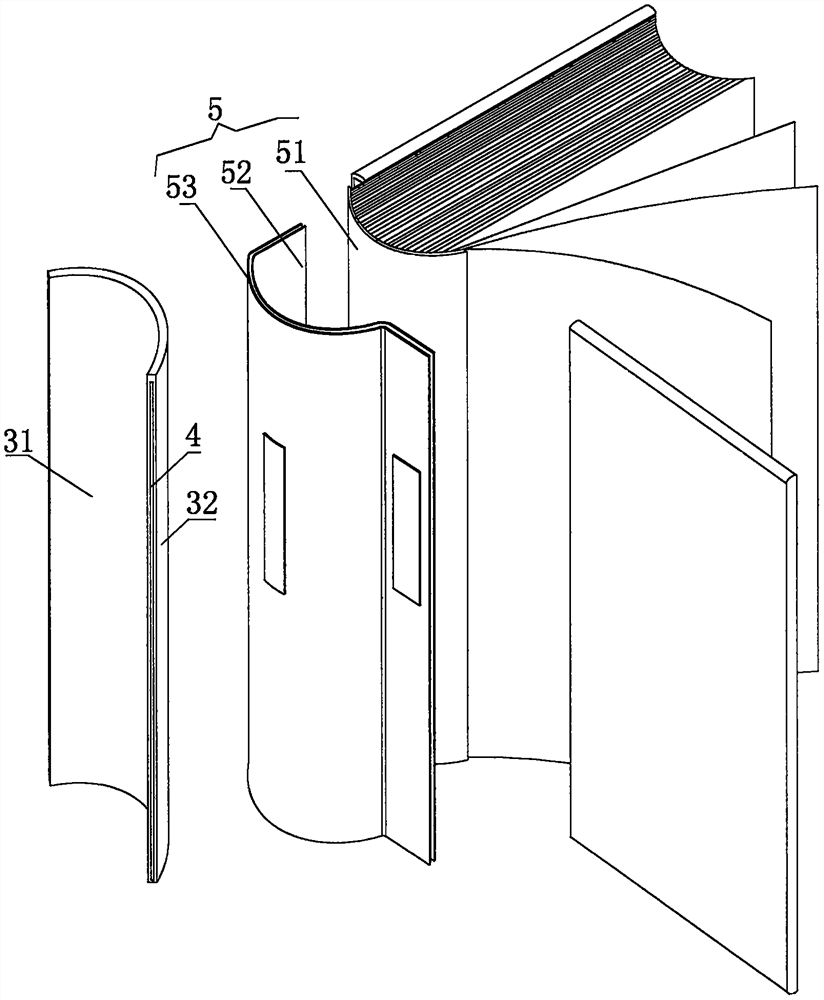

[0031] see Figure 3-4 , the strip holes 7 extending to the inside of the cover 1 and the back cover 2 are processed on the narrow sides of the cover 1 and the bottom cover 2 along the height direction. 1. The connection between the back cover 2 and the spine 3 at the reinforcement device 5 runs through to form a complete book.

[0032] see Figure 5-6 , the reinforcing device 5 inclu...

Embodiment 2

[0038] The front paper 51, the middle cloth 52 and the back paper 53 are superimposed and pass through the arc hole 4. The middle part of the front paper 51, the middle cloth 52 and the back paper 53 is located in the spine 3, and the front paper 51, the middle cloth 52 and the back paper 53 are separated. The spine 3 is divided in the middle, the remaining two parts of the front paper 51, the middle cloth 52 and the back paper 53 are inserted into the corresponding strip holes 7, and the front paper 51 and the back paper 53 are arranged with an adhesive on the surface, and It also provides a certain support force and hardness for the middle cloth 52, which is convenient for embedding. The two ends of the reinforcing device 5 are inserted into the strip hole 7 without bending. The paper 511 is located between the cover 1 and the back cover 2, and the front paper 51 and the back The outer surface of the paper 53 is coated with adhesive and inserted into the corresponding arc hol...

Embodiment 3

[0040] Change the structure of the reinforcement device 5, other parts are the same as the first embodiment

[0041] The reinforcement device 5 is changed to a single front paper 51 or a rear paper 53 to simplify the structure of the reinforcement device 5. The first RFID electronic tag 531, the second RFID electronic tag 532 and the third RFID are still pasted on the front paper 51 or On the rear paper 53, the outer surface of the front paper 51 or the rear paper 53 is coated with adhesive and inserted into the corresponding arc holes 4 and strip holes 7 respectively. The back ridge 32 is bonded, the two ends of the front paper 51 or the back paper 53 are bonded with the cover 1 and the back cover 2, and the cover in which the first RFID electronic tag 531, the second RFID electronic tag 532 and the third RFID electronic tag 533 are embedded 1. In the inner cover of the back cover 2 and the spine 3, the concealment of the electronic label is the best, and the assembly speed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com