Embroidery machine thread hooking device capable of automatically adjusting thread quantity

A self-adjusting and machine thread catcher technology, applied in embroidery machines, embroidery machine mechanisms, sewing equipment, etc., can solve problems such as insufficient optimization, and achieve the effects of stable operation, reduced wool, and stable tightening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

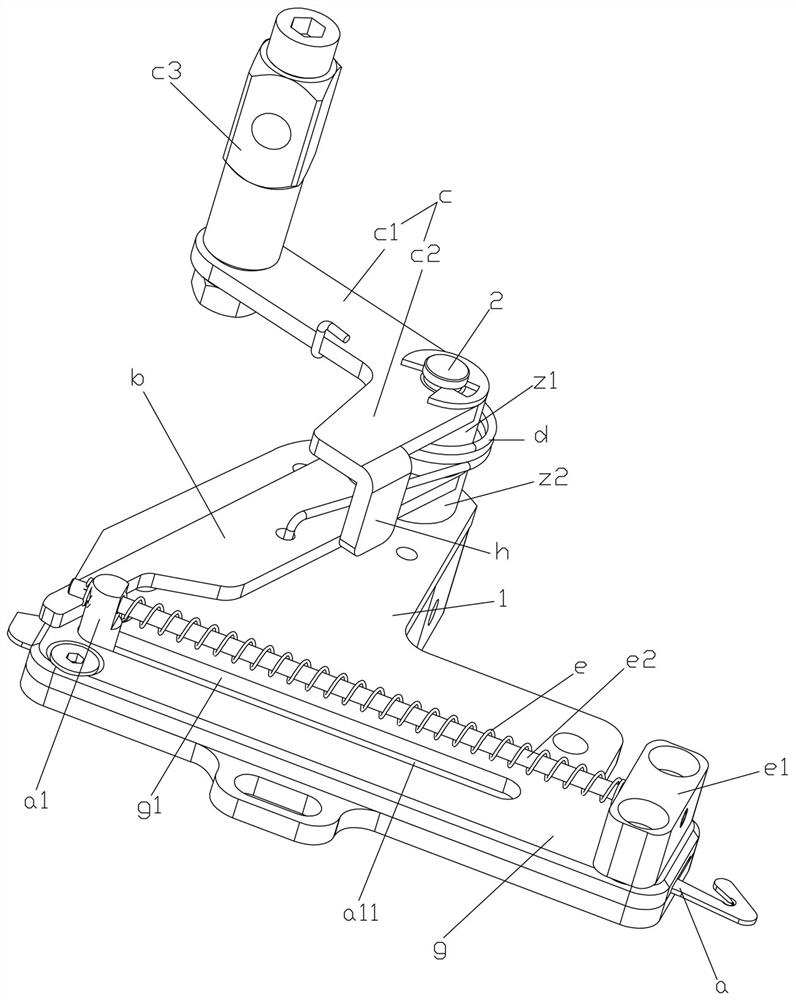

[0033] Example 1, such as Figure 1-3 As shown, an embroidery machine thread hooker capable of self-adjusting the amount of threads includes a base plate 1, a thread hook knife a mounted on the base plate 1, and a lower part for driving the thread hook knife a to move forward and out of the knife. The shift fork b and the upper shift fork c used to drive the lower shift fork b to swing back and forth between the front and rear, the base plate 1 is used as the basic component of the entire wire catcher to carry and install various components. Of course, the base plate 1 itself also needs Installed on the support structure in the machine head of the embroidery machine, so some installation holes also need to be opened. This is a conventional structure, which will not be described in detail here. In addition, after the substrate 1 is installed on the embroidery machine, it is usually preferred to be inclined forward and downward. The state is appropriate, and it is advisable to m...

Embodiment 2

[0046] Example 2, such as Figure 4-6 As shown, the difference between it and Embodiment 1 lies in the specific structural design of the elastic adjustment device, that is, the second structural style of the two preferred modes mentioned in Embodiment 1. Specifically, the spring e is a tension spring, except for this tension spring Stretching the spring, the elastic adjustment device also includes a spring stretching fit structure for stretching the spring e to form an elastic force, the spring stretch fit structure is to enable the spring to pull out the knife when hooking the thread knife and adjust the amount of thread In the process, the structure of the guide post a1 can be designed to position the rear part of the spring behind the guide post a1, so as to achieve the effect of stretching, but other structures that can make the spring stretch to form an elastic force are not excluded. This implementation A structure is introduced in , specifically, the spring tension fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com