Fabricated wall panel sliding assembly

A technology of sliding components and wall panels, which is applied in the field of architectural decoration, can solve the problems of bumping into patients, affecting the space inside the suite, danger, etc., and achieves the effects of easy cleaning, ingenious structural design, and beautiful decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

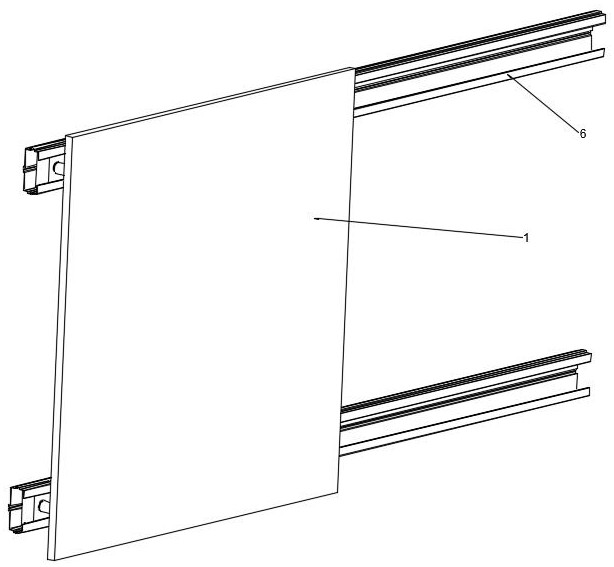

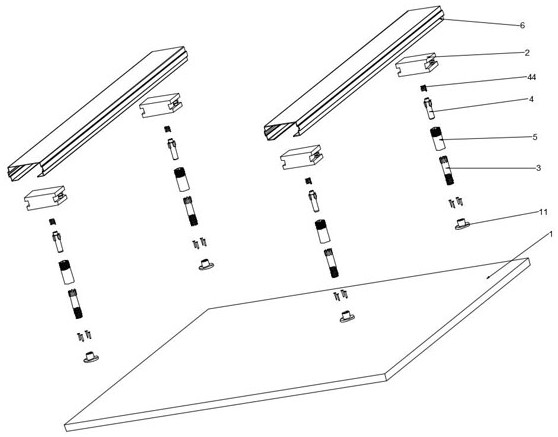

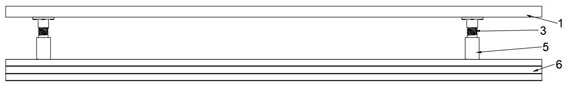

[0050] Such as Figure 1 to Figure 14 As shown, this embodiment provides an assembled wall panel sliding assembly, including: a panel 1 , a movable base 2 , a pressing head 3 , a movable tube 4 , a sleeve 5 and a track keel 6 .

[0051] Four fixing seats 11 are installed on the panel 1 in this embodiment, and the fixing seats 11 are respectively fixed to the four corners of the panel 1 by screws or bolts. The fixing seats 11 are used to connect with the pressing head 3. When pressing the panel 1, the four The fixed seat 11 at the first position is linked with the movement of the pressing head 3 at the same time.

[0052] One end of the pressing head 3 in the present embodiment is provided with eight first wedge-shaped posts 31, and the eight first wedge-shaped posts 31 are evenly arranged along the circumferential direction of the pressing head 3, and the other end of the pressing head 3 is provided with threads, and the threads and the fixing Seat 11 is fixedly connected. O...

Embodiment 2

[0073] This embodiment provides an assembled wall panel sliding assembly, which is different from Embodiment 1 in that:

[0074] In this embodiment, only two fixing seats need to be installed on the panel, and the distance between the two fixing seats corresponds to the distance between two track keels parallel to the original wall; at the same time, the pressing head, movable pipe, sleeve And two movable bases are also installed correspondingly, and after they are assembled, the panel can be moved up or down or slide left and right, saving materials, easy to install and disassemble, and easy to operate.

[0075] For other specific structures, reference may be made to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com