Breeze vibration suppression device of power transmission tower

A technology for vibration suppression and transmission towers, applied to towers, building types, buildings, etc., can solve problems such as inability to completely suppress vortex-induced wind vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

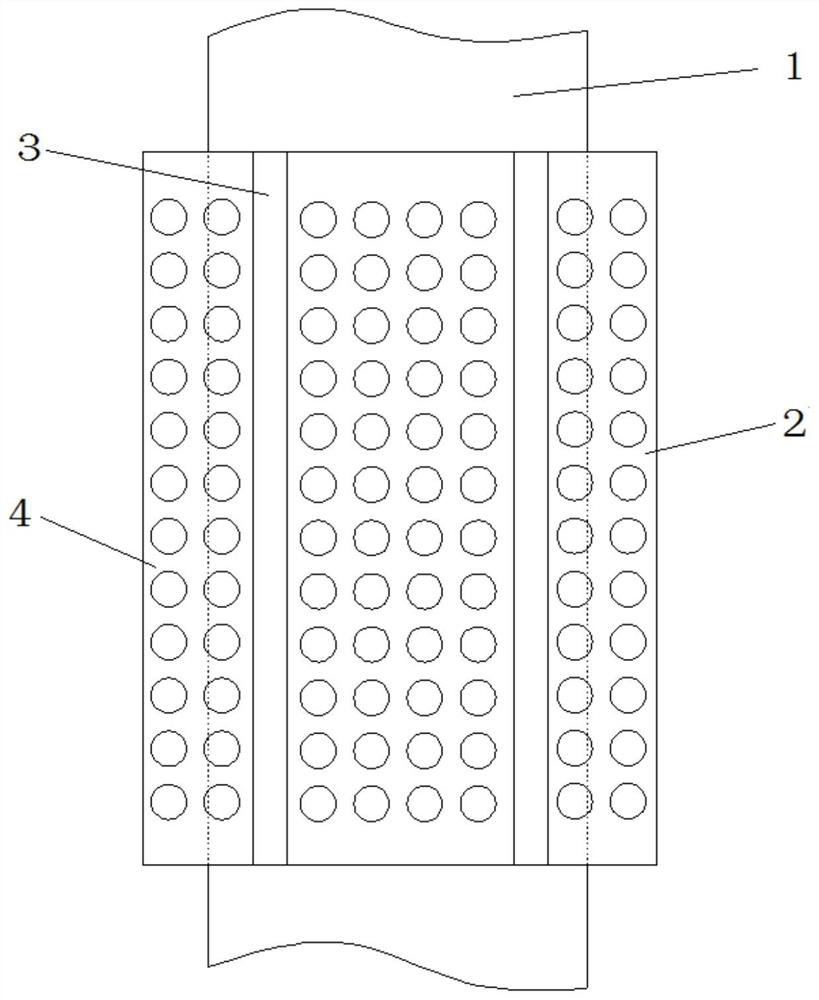

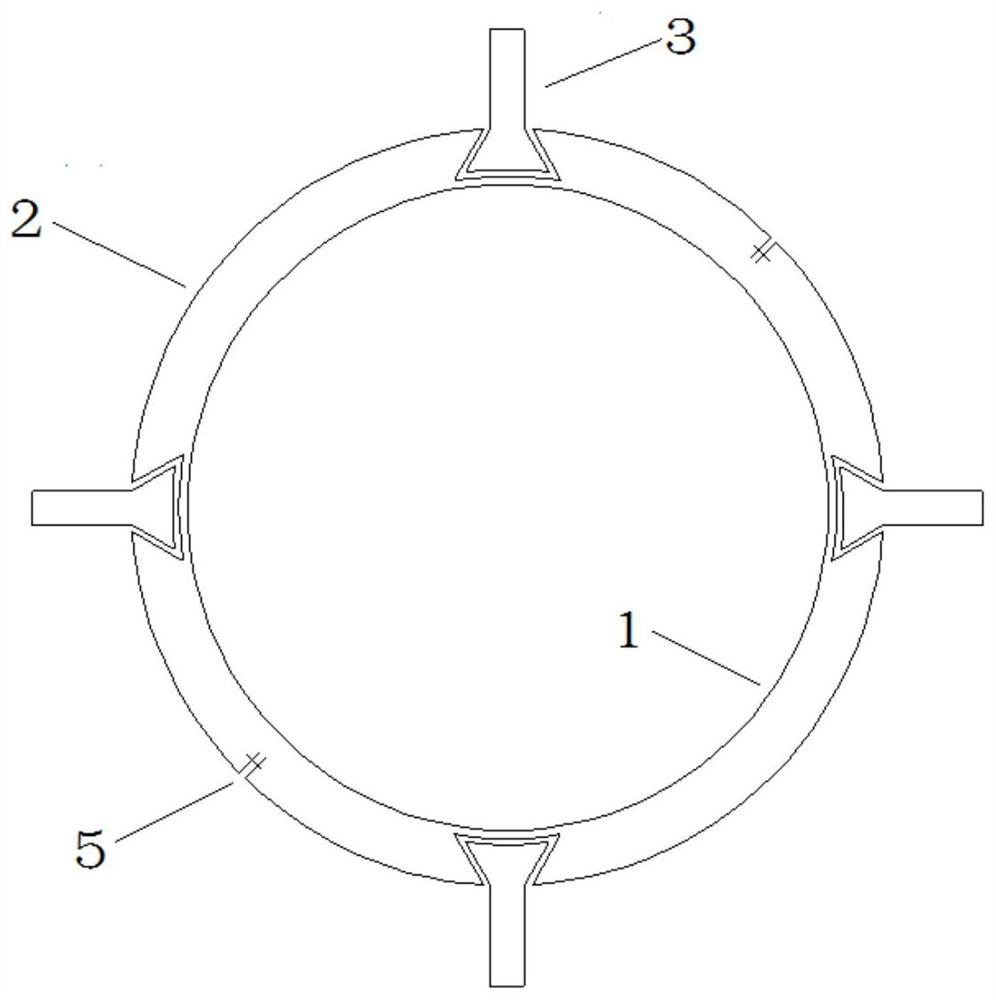

[0032] This embodiment provides a transmission tower breeze vibration suppression device, the front view is as follows figure 1 As shown, it includes: a sleeve 2; the sleeve 2 is a hollow cylindrical structure, fixedly sleeved on the steel pipe of the transmission tower, and a plurality of holes 4 are arranged along the axial direction of the sleeve 2.

[0033] The sleeve 2 includes:

[0034] At least two curved cylinders;

[0035] All the arc cylinders are combined along the cylinder sides to form a cylinder structure.

[0036] There are two arc cylinders.

[0037] Also includes a plurality of bolts 5;

[0038] Screw holes are provided on each arc-shaped cylindrical surface, and the cylindrical structure is formed by combining bolts 5 .

[0039] The diameter of the cylindrical structure is equal to the diameter of the steel pipe of the transmission tower, and the cylindrical structure is fixed on the steel pipe of the transmission tower by tightening the bolts 5 .

[004...

Embodiment 2

[0052] This embodiment provides a transmission tower breeze vibration suppression device, the device is installed on the steel pipe of the transmission tower, and the device is installed on the steel pipe rod 1, the front view is as follows figure 1 shown, including:

[0053] The sleeve 2 and the spoiler 3 are provided with circular openings, and the circular openings play the role of breaking the vortex, which can not only enhance the wind vibration control effect, but also reduce the wind resistance of the cylindrical sleeve itself;

[0054] The spoiler strip 3 is evenly installed on the outside of the sleeve 2 along the axis of the sleeve 2 .

[0055] The sleeve 2 is made of anti-aging metal material, including:

[0056] Two semi-cylindrical surfaces and bolt 5;

[0057] The radius of the semicircle of the semi-cylindrical surface is equal to the radius of the steel pipe of the transmission tower;

[0058] The semi-cylindrical surface is butt-mounted to the outer side of...

Embodiment 3

[0069] This embodiment provides a breeze vibration suppression device for a power transmission tower, which is composed of a cylindrical sleeve and a spoiler, the cylindrical sleeve surrounds the steel pipe rod, and the spoiler is externally connected to the cylindrical sleeve.

[0070] The cylindrical sleeve consists of 2 semi-cylindrical surfaces connected by 4 bolts at both ends. The cylindrical sleeve has built-in grooves every 90°, and a spoiler is inserted into each groove. The height of the spoiler is 10cm, and it is made of PVC material. In the area between each groove of the cylindrical sleeve, 4 columns of Φ2cm round holes are evenly distributed.

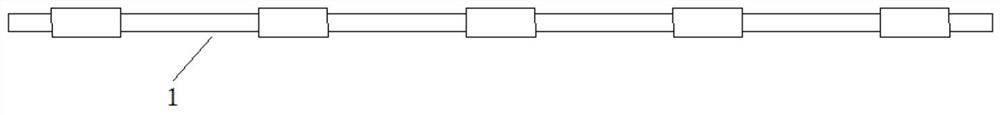

[0071] Such as image 3 According to the slenderness ratio and wind vibration conditions of the steel pipe rod shown, 5 to 7 devices of the present invention are installed at equal intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com